ABSTRACT

Nanotechnology is one of the latest innovations in this time that has shaped the today’s lifestyle. The properties of nanomaterials have attracted not only scientists and researchers but also businesses, due to their huge economical potential and growing public health concerns. This article explores one of the branches of nanotechnology i.e. anti-microbial finish. Textile with anti-microbial function has been developed for promoting health and hygiene of human safety. At present the whole world is suffering from COVID-19 pandemic and everyone is looking forward for the health and hygiene options to stay safe. Some anti-microbial finishes are also effective to tackle the virus also.

INTRODUCTION

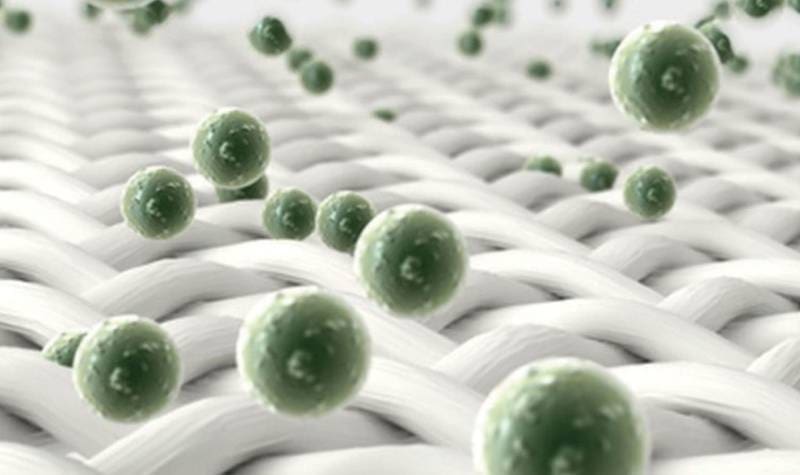

In the current global crisis from corona virus pandemic, it has arisen many clinical and public healthcare challenges and nanotechnology is playing a significant role in it. There has been an increase in the public awareness in terms of health and hygiene and therefore creating growth in demand of healthcare or health protective products. Textile materials particularly made of natural fibres supply an outstanding medium for microbial growth due to their large surface area and ability to retain moisture. Moreover, the problem of degeneration of natural products such as natural wood, cotton, or wool by microorganisms or insects has been faced by human beings since they were first started to be used. Therefore, to prevent undesirable effects such as degradation, unpleasant odours, and potential health risks, textiles are treated with antimicrobial agents. With the help of nanotechnology textiles are now providing us with number of anti-viral and anti- microbial products that are non-toxic and environmentally friendly, allowing for exceptional hygiene standards in all areas of work and life. As a result, it is possible to create a healthier living and working environment and to offer holistic solutions to people with a diminished immune system. Nano-based surface coatings or finishes can prevent the spread of bacteria, fungi and viruses over infected surfaces of high-traffic objects, such as door and window handle in public places, hospitals, public buildings, schools, frequently used hygiene textiles etc.

ANTIVIRAL AND ANTIMICROBIAL NANOCOATINGS

Among other mechanisms, viruses and bacteria can spread when a person comes in contact with a site where germs have settled, such as a door frame, handrail, infected textile or medical device. Garment and textile goods provide favorable environments for bacteria or fungi for their growth. Longer survival length of pathogenic microorganisms on textile materials leads to the spreading of diseases. In order to diminish microbial infections caused by textile goods, antimicrobial textile materials could be used especially in health care facilities.

Prokaryotic structural components of micro-organism consist of macromolecules such as DNA, RNA, proteins, polysaccharides, phospholipids, or some interdependent combination. The macromolecules are made up of primary components such as nucleotides, amino acids and sugars. The sequence in which the components are put together in the macromolecule, called the primary structure, determines numerous properties that the macromolecule will have.

AGENTS

As per research done till now nanoparticles of metals like gold, silver, copper, zinc, have shown effective results as antimicrobial agents. The antibacterial properties of gold and silver are well known for their effectiveness in reducing the growth of several microorganisms. Due to high cost of silver and gold material researchers have focused their attention on exploring the possibility of using copper as the ultimate antimicrobial agent. In the recent research copper has been approved as an anti-viral agent along with its anti-bacterial property and are being used in making antiviral textiles. Just like silver copper also have the same properties and nature towards viruses and microbes.

MECHANISM

Exposure to copper have resulted in death of microorganism within minutes. Copper toxicity to microorganisms is achieved through several parallel mechanisms. These include plasma membrane permeabilization, membrane lipid peroxidation, alteration of proteins and inhibition of their biological assembly and activity, and denaturation of nucleic acids. Redox between Cu+ and Cu2+ results in the formation of hydroxyl radicals that may attack amino acids, especially histidine and proline, causing substantial protein alterations and even protein cleavage. Viruses are highly affected by the copper induced damage since they do not have tolerance and repair mechanisms, such as DNA repair mechanisms present in bacteria and fungi.

PROCESS

There are several ways by which chemical used as an antimicrobial activity can be applied to the textile material. For antimicrobial finish textile one can use exhaust, pad-dry-cure, coating, spray or foam techniques. The antimicrobial substances can also be applied by directly adding into the fibre during the spinning stage which can increase the life span of functional property of the fabric.

TESTING METHOD

Whether the antimicrobial agent is infused into the textile as a thread or applied to the textile surface as a liquid, testing is crucial to ensure performance. Textile testing help in evaluating the effectiveness of antibacterial finishes. Testing is also used to conclude about the quality of end products and their extent of microbial resistance. To measure the efficacy of antimicrobially treated textiles, test methods used under controlled conditions are needed for reproducible results. The antimicrobial activities are generally tested for both quality and quantity through standard tests. Laundering is a main source of fabric degradation, so companies often ask for standardized laundering prior to tests. Some of available standards are AATCC 100-2004 Assessment of Antibacterial Finishes on Textile Materials, AATTC Test Method 147-2004 Parallel Streak Method, AATTC Test Method 30-2004 Antifungal Activity and Assessment on Textile Materials: Mildew and Rot Resistance of Textiles.

HEALTH AND ENVIRONMENT ISSUE

An antimicrobial hampering the growth or leading the death of microorganism may be harmful to other living species including human being. More than 250 commercially known microbiocides, and several chemical formulations based on these antimicrobe were available in the market. The multiplicity of antimicrobial chemicals introduced the variety in chemical and physical properties in finished products. Concentration of germicide chemical influences the mechanism of microbial resistance. At an increased concentration multiple cellular and metabolic targets were possible, and at reduced concentrations fewer cellular targets were indicated.

The release of antimicrobial through the wash- off liquor of the finished fibrous article would introduce the hazard to aquatic life.

END USE

Antimicrobial nanocoating can be applied by spraying or dipping and adhere to various surfaces such as glass, metals and various alloys, copper and stainless steel, marble and stone slabs, ceramics and tiles, textiles and plastics. Various products made up of polymer can incorporate these agents at its molten stage which can help in long lasting functioning of these nano particles.

CONCLUSION

With advent of new technologies, the growing needs of the consumer in the wake of health and hygiene can be fulfilled without compromising the issues related to safety, human health and environment. Scientists all over the globe are working in the area and a few of them reported to have used antimicrobial finishes and chemicals to make the fabric having antimicrobial properties. To carve a niche for textile materials, this kind of value adding finishes in our day to day garments are the need of the hour.