GRAZ, MAY 02, 2023. International technology group ANDRITZ will be presenting its innovative nonwovens production and textile-recycling solutions at ITMA in Milan, Italy, from June 08 to 14 (hall 10, booth A105 and hall 09, booth C205).

The ANDRITZ product portfolio covers state-of-the-art nonwovens and textile-production technologies such as air-through bonding, needlepunch, spunlace, spunbond, wetlaid/WetlaceTM, converting, textile finishing, airlay, and natural fiber processing. For the textile recycling sector, ANDRITZ offers complete lines and individual components for textile fiber preparation, mechanical and chemical recycling, and combined processes.

KEY FOCUS FOR ANDRITZ NONWOVEN (HALL 10, BOOTH A105)

Sustainability is a serious responsibility for the entire textile and nonwoven industry and will continue to be so in the years and decades to come. Our nonwoven production solutions and products are classified as sustainable if they support customers in achieving their sustainability goals. This means they help protect the environment, contribute towards decarbonization and carbon neutrality, enable the use of natural, biodegradable and/or recycled fibers, reduce the use of valuable resources such as energy, water or raw materials, or recycle waste and foster a circular economy. Thus, airlay, spunlace and needlepunch lines, and bast fiber processes using 100% bio-based, natural fibers and/or recycled fibers, as well as Wetlace and Wetlace CP lines to produce biodegradable wipes, and needlepunch lines equipped with web weight correction systems are all classified as sustainable products and solutions.

The presentation of a complete PA.3000 elliptical cylinder pre-needler at ANDRITZ’s booth is one of the highlights at this year’s ITMA in Milan. The PA.3000 is the ideal solution for processing fiber mats, featuring new capabilities to “freeze” the evenness of the fabric as it operates with no internal draft and with more than 70% extra surface-impact needling capacity than the existing technology. It is the ideal solution for markets in which the visual aspect of the products is important and that have high productivity requirements. ANDRITZ will also present its ProWinTM technology for profile web weight correction, which is used to optimize fabric evenness and provide a faster return on investment in the needlepunch market segment. By combining the well-known and proven technologies ProWidTM and ProDynTM, ProWin allows customers to achieve the lowest CV-ratio ever, reaching more demanding markets and saving up to 2% additional fibers compared to ProDyn.

Another main topic at ITMA will be digitalization. ANDRITZ offers a broad and constantly growing range of innovative products and services in the industrial digitalization sector under the brand name Metris. One focus area is the Metris all-in-one digitalization platform, which provides full support for industrial plants throughout their entire life cycle. It combines a complete set of functionalities for professional production management, simulation and optimization using the latest artificial intelligence methods, plus cyber security, and condition monitoring with smart sensors in an integrated approach. ANDRITZ will offer a live demonstration of the platform at its booth at ITMA.

KEY FOCUS FOR ANDRITZ TEXTILE RECYCLING (HALL 09, BOOTH C205)

ANDRITZ is at the core of the movement to provide sustainable solutions and state-of-the-art recycling processes for pre- and post-consumer textile waste and collaborates with internationally renowned partners to do this. At ITMA, ANDRITZ will pesent its textile-recycling processes, including textile fiber preparation, mechanical and chemical recycling, and combined processes.

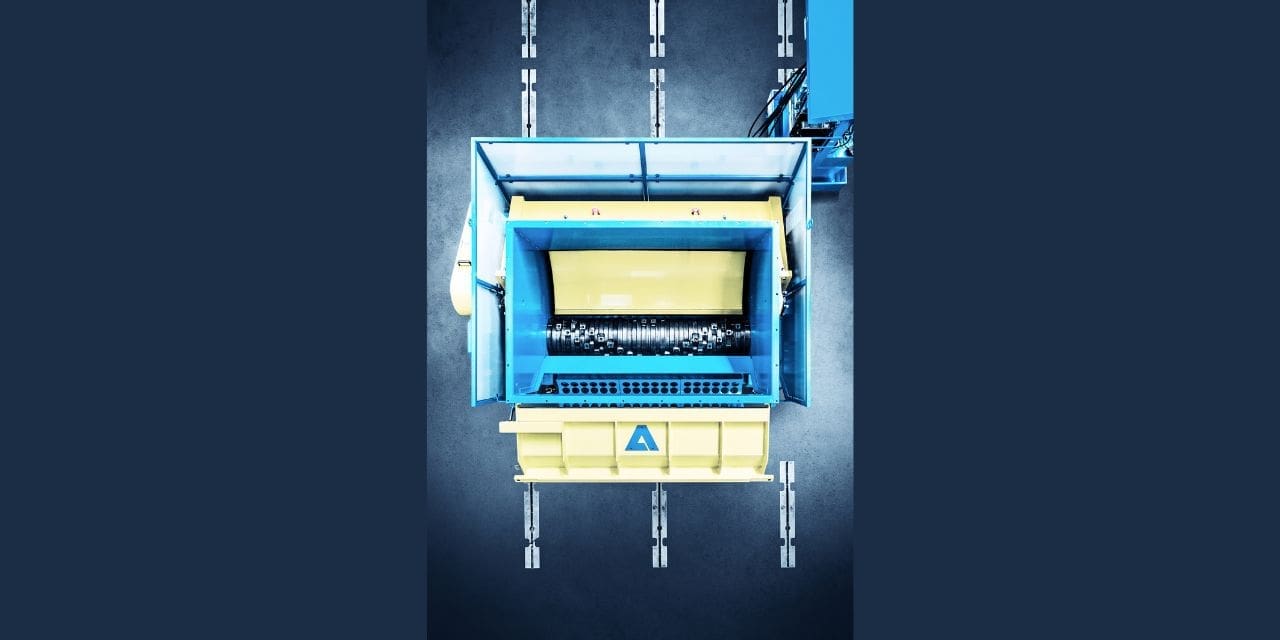

One highlight is the ADuro F fine grinder, which will be showcased at the ANDRITZ booth. The ADuro F is used for efficient fine grinding of pre-shredded textile input material down to a very accurate granulate size, while keeping dust to an absolute minimum. Learn more at the ANDRITZ booth, where you can also see an augmented reality demonstration.

Another key topic at ITMA will be ANDRITZ chemical/circular textile recycling technologies, where fiber preparation – for example using ADuro shredders and fine grinders – plays an essential role. Chemical recycling of textile waste is a vital and emerging business area. ANDRITZ is a key player here because the core process steps involved can use the same equipment as in existing pulp and paper technology, where ANDRITZ is an acknowledged expert.

The second exhibit at the ANDRITZ Textile Recycling booth is a Jumbo tearing module, which has been designed for recycling a high volume of textiles, whether post-consumer textile waste or industrial textile waste. It includes high quality tearing equipment for smooth production of nonwoven fiber and yarn.

What is more, ANDRITZ has teamed up with Pellenc ST and Nouvelles Fibres Textiles in an ambitious partnership aiming to drive the shift towards an industrial-scale circular economy for textiles. This partnership is the result of a long-standing collaboration. The three companies are now joining forces to set up the very first industrial line in France to combine automated sorting and recycling technology. At ITMA, the companies will present the latest developments.

The entire ANDRITZ Nonwoven and Textile Recycling team is looking forward to welcoming customers to our booths (hall 10, booth A105 and hall 09, booth C205).