Innovative solutions in challenging technological applications are driven by Heberlein jet technology.

March 7, 2024, Heberlein Technology AG, Wattwil, Switzerland – At the next Techtextil in Germany, special technology for producing cutting-edge technical fabrics with exquisite qualities will be showcased. Leading provider of air texturing and interlacing jets, Heberlein, intends to persuade attendees with essential components, such the most recent PolyJet-TG-3, that can affect both yarn characteristics and processes.

Technological developments in high-performance yarns have led to adaptable substitutes for conventional raw materials across various sectors and uses. Presently, customized filament yarns satisfy particular requirements in a variety of industries, including construction, automotive, aviation, maritime, and medical. Furthermore, Heberlein’s Swiss-made essential parts are leading these advancements by integrating cutting-edge new technology into the center of filament yarn innovation.

A new generation of spinning jet is the PolyJet-TG-3.

Magnification of the yarn evenness with a PolyJet-TG-3-HP405A/WO70 (TopAir) looks amazing for manufacturers of demanding technical yarns. The latest generation of jets impresses with robust, dependable knots for high tenacity yarn (HT and HMLS) and an unrivaled even and consistent interlacing density. The most recent PolyJet-TG-3 from Heberlein can reach speeds of over 12 knots per meter with 1100f98dtex and 1670f98dtex. Smaller differences are seen in the tensile strength, elongation, and elasticity of the yarn, which contributes to enhanced bobbin unwinding behavior and overall quality improvements.

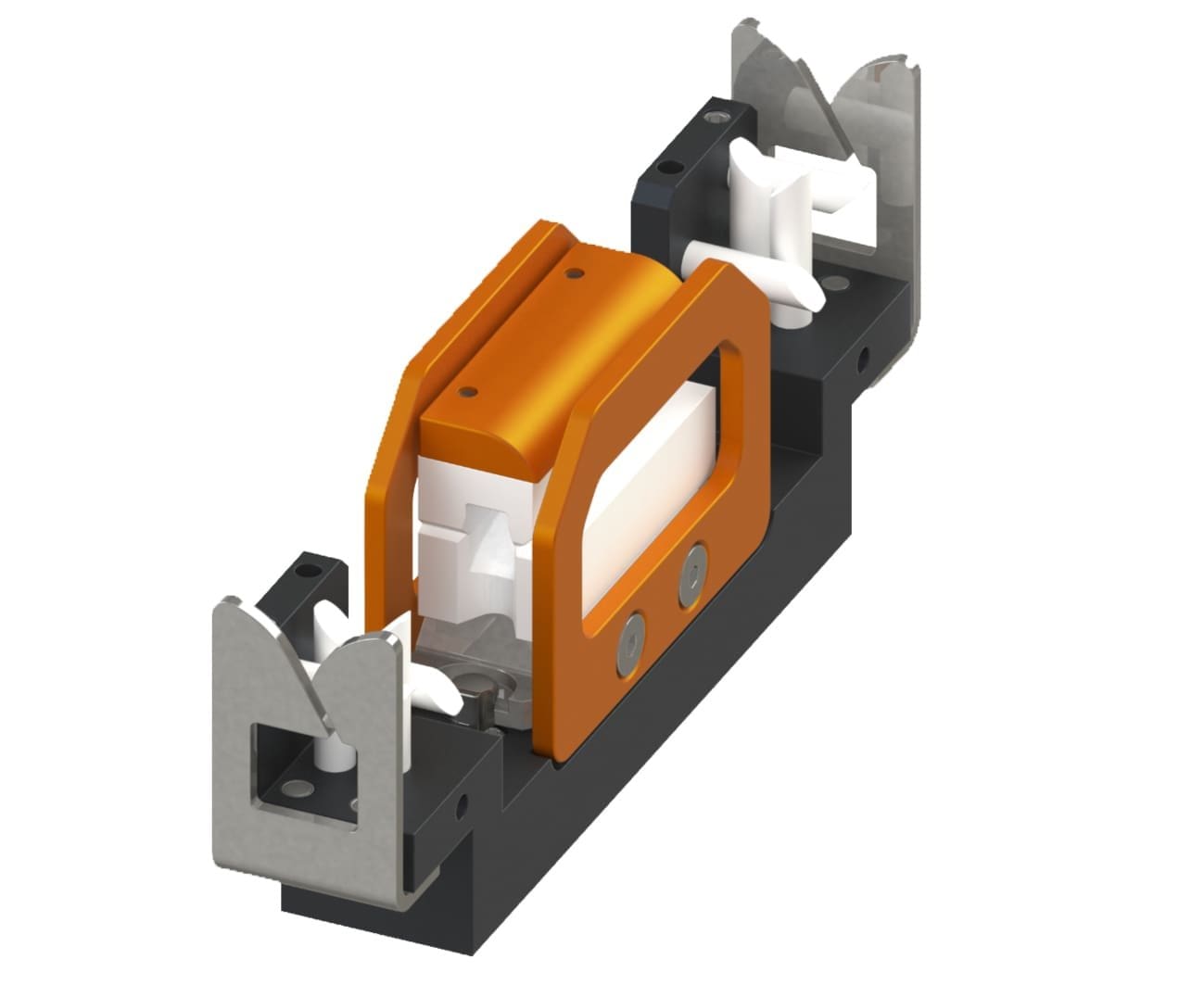

All of these elements are typical of Heberlein advantages. Technical yarns’ high-performance air interlacing jets include a special quick-release mechanism that allows jet packs to be swapped out in a matter of seconds with only a single 180° spin. Additionally, they have a small, space-saving design with a roll bar to shield the surfaces made of ceramic.

For technical fibers with great strength, use AirSplicer-3 Flex.

Yarn splicers provide a homogenous, tear-resistant splice of material free of knots. Compressed air is all they require. When exceptional strength properties are required for a variety of technical fiber applications, Heberlein’s AirSplicers generate first-rate splices.

Glass, carbon, aramid, and synthetic multifilament yarns can all be spliced with AirSplicer-3 Flex. The range varies based on the substance and can reach 500dtex to 30,000dtex. Its unique width-adjustable design, which is perfect for technical and textile multifilament yarns, results in flexibility. The new splicer replaces two older devices, AirSplicer 40-2 and 70-2, in a single device.

Heberlein is excited to answer any questions regarding jets and splicers from visitors to Techtextil Frankfurt in Hall 12.0 at booth B01. Experts at Heberlein will be especially eager to discuss the advantages of the unparalleled yarn evenness that the newest spinning jet technology achieves.