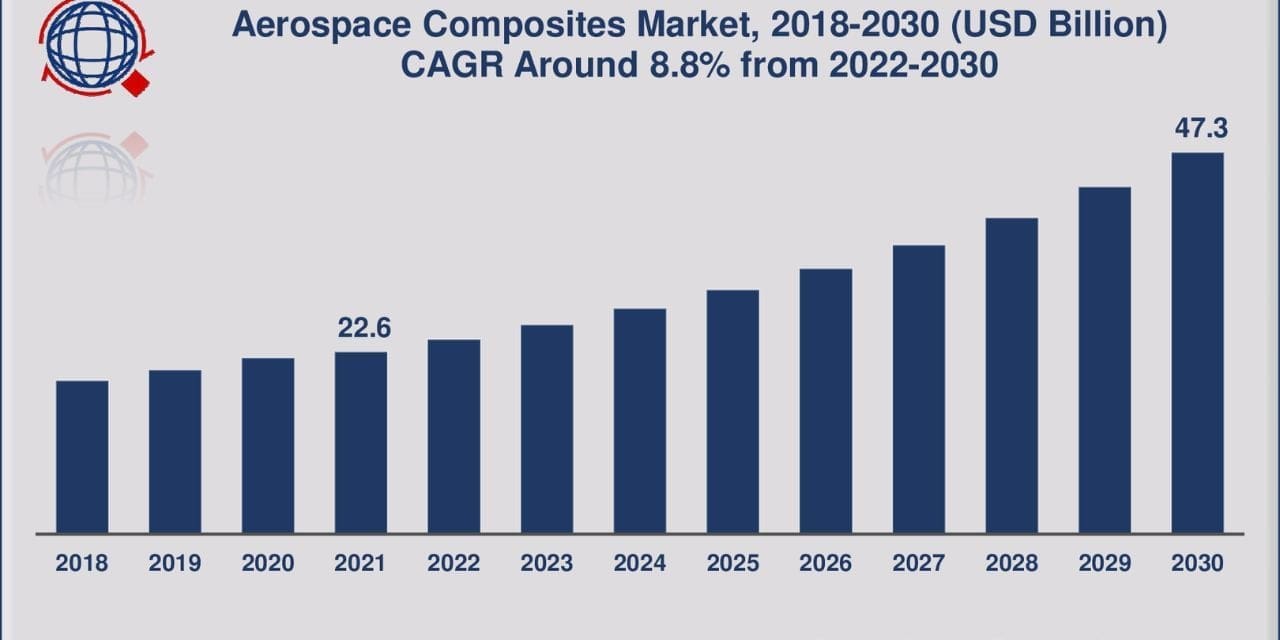

The report “Aerospace Composites Market by Fiber Type (Carbon Fiber Composites, Ceramic Fiber Composites, Glass Fiber Composites), Matrix Type, Manufacturing Process (AFP/ATL, Resin Transfer Molding), Application, Aircraft Type, and Region – Global Forecast to 2027“, is projected to grow from USD 26.6 billion in 2021 to USD 51.6 billion by 2027, at a CAGR of 11.7% during the forecast period. The market is growing due to the increase in the demand for high-performance materials, with properties such as low weight, high strength-to-weight ratio, good tensile strength, and electrical conductivity.

Browse

• 180 Market data Tables

• 51 Figures

• 210 Pages and in-depth TOC on “Aerospace Composites Market – Global Forecast to 2027”

Some of the prominent key players are:

- Solvay (Belgium)

- Toray Industries, Inc. (Japan)

- Mitsubishi Chemical Holdings (Japan)

- Hexcel Corporation (US)

- Teijin Limited (Japan)

- SGL Group (Germany)

- Spirit AeroSystems (US.).

Opportunity: Reduction of cost of carbon fibers is an excellent opportunity in the aerospace composites market

The main raw materials used for the production of carbon fiber composites are polymeric resins and carbon fibers. The cost of carbon fibers is directly proportional to the cost of precursor raw materials from which they are obtained. Carbon fibers are currently obtained from polyacrylonitrile (PAN), whose cost in aerospace applications is approximately USD 90 per kilogram. The development of low-cost and high-yield precursors for making aerospace grade carbon fibers would significantly reduce the cost of carbon fibers. These low-cost precursors for carbon fibers would bring down the cost of aerospace-grade carbon fibers. The reduction in the cost of carbon fibers would reduce the cost of carbon fiber aerospace composites, thereby driving the market.

AFP/ATL is expected to account for the largest share in the aerospace composites market during the forecast period.

The ATL/ AFP processes use computer-guided robotics to lay one or more layers of carbon fiber tape onto a mold to create a part or structure. AFP/ATL machines help in increasing the production rate and precision in the manufacturing of aerospace composites and composite parts. AFP is a hybrid process between filament winding and tape laying, and hence, it combines the benefits of both the processes. This process is less time-consuming and leaves out very less scrap of raw materials, as compared with manual processes.

Europe is expected to account for the largest share in the aerospace composites market during the forecast period.

Europe accounted for the largest market share in the aerospace composites market due to high demand from commercial aerospace industries. Moreover, it is home to many key aerospace composite manufacturers, such as SGL Carbon, Solvay, and TenCate. Increased deliveries of Airbus aircraft primarily drives the composites material demand in Europe. Apart from this, the region develops military aircraft and helicopters