Arshin Shaikh

PG Scholar, PG Department of Textile Science and Apparel Design,

S N D T Women’s University, Mumbai

Mr. Muntazir Ahmed,

Ex. Principal Scientist ICAR, CIRCOT

Visiting Faculty, PG Department of Textile Science and Apparel Design,

SNDT University, Juhu, Mumbai.

Introduction

The word ‘Knitting’ was derived from the ancient Sanskrit word ‘Nahyati’. Presently, Knitting is the second most popular method of fabric production, which was initiated during 1000 B.C. by using fingers only. The second stage of its evolution is ‘Hand Knitting’ (using 2 pointed needles), which was known and practised during 256 A.D. Its speed is up to 100 loops per minute. This method is continued for domestic purposes. Machine Knitting was started in 1589 with the invention of the first knitting machine by Reverend William Lee of Calverton near Nottinghamshire, England. The speed of the original model was 500 to 600 loops per minute with a gauge of 8 needles per inch. Though the knitting machine was invented in 1589, it took about 300 years to start knitting in India when the first hosiery unit was installed in Kolkata in 1892.

Recent developments in machines and fabrics, together with versatility and flexibility in manufacturing and styling, have increased the scope of knit fabric from its original use in hosiery. Presently, knitting has made great progress, and the reason for its growth is low capital cost, economical fabric, design setting easy and quick, simple and short process, garment knitting, advanced technical textiles, special end uses like sports, swimming, socks, gloves, etc. Lately, knitting has been introduced in textile courses in our country, but its progress in the educational system is still very slow, with poor facilities. This basic study has been carried out by getting inspiration from finger knitting. The experiment aims to explain the principle of loop formation and fabric construction, which in turn will help to understand the process of loop formation of machine knitting.

Materials and method

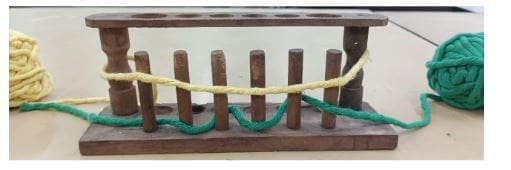

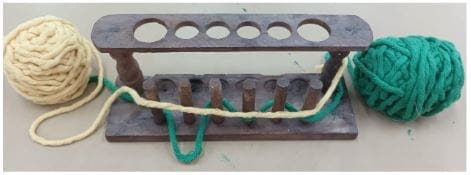

The easily available test tube stand (Fig 1) is the only equipment for this experiment. Pegs of the

Fig.1. Test Tube Stand

test tube stands are comparable to the vertical needles of a single jersey circular knitting machine. Two yarn balls of green and yellow colours are chosen to feed alternately for the intermeshing of two different coloured loops. Coloured yarns are used for a sharp distinction between old and new loops and also for the formation of horizontal stripes of respective colours. Coloured loops will better help to explain the basic structure of the fabric and loop formation during knitting.

The selected tt stands 6 pegs, comparable to 6 needles of a single jersey knitting machine having vertical needles. Loop formation by this method is systematically explained as follows:

STEP 1: Green yarn is loosely fed, forming set-up loops around all the pegs, as shown in Fig.2

Fig.2

STEP 2: Yellow yarn is fed, laying it at the front of pegs as indicated in Fig. 3.

Fig.3

Fig.3

STEP 3: The old green loop of the second peg is pulled out for cast-off, as explained in Fig. 4.

Fig.4.

STEP 4: The old green loop is taken over yellow and passed behind the peg, leaving a new yellow loop on the stem of the peg, as seen in Fig.5.

Fig.5.

In machine knitting terminology, this action is known as knock-over or cast-off.

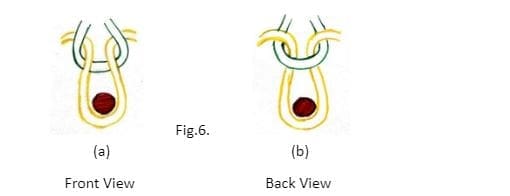

Immediately after knock-over, the newly formed yellow loop is pulled through the old green loop for the appropriate loop length, as given in Fig.6.

STEP 5: The first course is completed by knitting loops sequentially, one after the other, as presented in Fig.7. Therefore, this method is a sequential or individual knitting system. Now, the frame is ready to start with the formation of the second course.

Fig.7

Now, the green yarn is fed to all pegs, and old loops of yellow yarn are ready to knock over at all the pegs sequentially for the formation of a new course, as observed in Fig. 8.

Fig.8 Alternate feeding and knock over of both yarns will continue for the production of the entire length of the fabric.

Fig.8 Alternate feeding and knock over of both yarns will continue for the production of the entire length of the fabric.

Fig.9 During knitting, green has fed and cast off the process of previously formed yellow loops are continued.

Fig.10 Formation of the yellow course is being completed with the knock-over process at the last peg.

Fig.11 Technical back of long fabric being Fig.12.Technical face

knitted is seen with a curling tendency (legs of loops in “V” formation)

at selvedges.

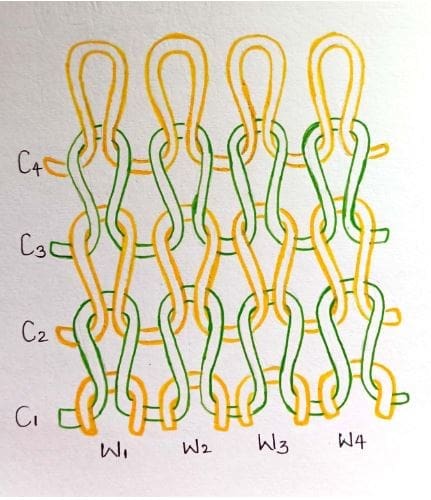

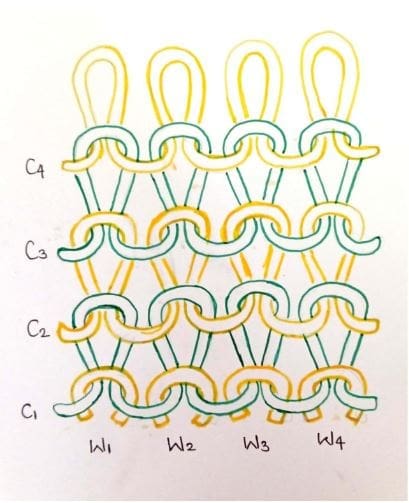

Fig.13 Loop diagram derived from the technical face of the fabric as given in Fig. 12.

Fig.14 Technical back (Head and feet of lopes in the form of opposed semi-circles).

Fig.15. Loop diagram derived from the technical back of the fabric, as shown in Fig. 14.

Result and Discussion:

- The knitting action started at step 1 and completed at step 4. Loop formation was done with the help of human fingers, but the process is similar to machine knitting, where the action is automatic. Therefore, this simple tool can be used for the initial training of knitting learners.

- Fig 6 indicates two views of the newly formed loop. Therefore, knitted loops can be classified into two types – front & back; at the same time, the basic definition of the knitting process can also be derived as pulling a new loop through the previously formed loop.

- With the help of these two loops, the concept of four basic weft-knit structures can be explained by arranging face and back loops in 4 different orders.

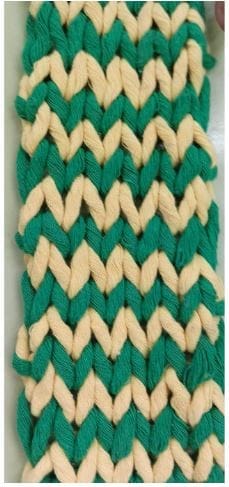

- Identification of the technical face and back is self-explanatory in Fig. 12 and 14, respectively. Two legs of loops are seen in a ‘V’ formation together with a smooth and shining surface at the face side in Fig. 12. Clearly visible rows of opposed semicircles formed by the head and feet of loops with rough and dull surfaces appeared on technical back in Fig. 14.

- On the technical face (Fig. 12 and 13), the loops are visible in the entire fabric like ‘bricks’ of a building in such a manner that each loop is interconnected with its four neighbouring loops. The green loop is connected with two green loops at the right & left and two yellow loops at the top & bottom and vice versa. Each green is drawn through previously formed yellow, and yellow is drawn through green, confirming that knit fabric is produced by pulling a new loop through the old loop.

- Another important observation from the technical face (Fig. 12) is the horizontal and vertical alignments of loops. These two types of arrangements are known as courses and wales. Horizontal rows are called courses, and vertical columns are known as wales. One course is made of one single coloured loops, whereas in wales, alternate loops are made of green and yellow loops. Six numbers of wales are identical with six pegs in the tt stand. Confirming that each wale is produced by one peg.

- The yarn path derived from the face and back of the fabric are represented in Fig. 13 & 15, respectively. These two loop drawings are self-explanatory to understand the basic construction of plain single jersey fabric.

- Fig. 11 communicates the curling tendency of knit fabric, which is observed at the two selvedges of the fabric.

Further Scope:

- Instead of tt stand, straight and circular wooden frames with more pegs can be prepared for a better explanation of flat and circular knitting techniques.

- Two rows of pegs for double jersey structures.

Conclusion:

In the form of straight and circular peg frames, this system can be utilized as an educational tool to demonstrate the concept of loop formation and the basic fabric structure of flat and tubular fabrics.

Acknowledgements:

I wish to express my sincere gratitude to

- Dr. Anshu Sharma, Professor and Head, PG Department of Textile Science and Apparel Design, SNDT University, Juhu, Mumbai, for her kind permission to carry out this study.

- Ms. Nikhila Rane, Asst Prof., SNDT University, Juhu, Mumbai, for her appreciation, encouragement and valuable suggestions.

- Dr. Rajeshree Amit Shinde, Asst Prof., Svt College of Home Science (Autonomous), SNDT Women’s University, Juhu, Mumbai, for providing a basic tool to carry out this experiment.

- References:

- David J. Spencer, Knitting Technology, Pergamon Press, Great Britain.

- Prof. D.B. Ajgaonkar, Knitting Technology, Universal Publishing Corporation, Mumbai, India.

- Sadhan Chandra Ray, Fundamental and Advances in Knitting Technology, Woodhead Publishing India Pvt. Ltd., New Delhi.

- Encyclopedia of Textiles, American Fabrics and Fashion Magazine, Prentice–Hall Inc. NJ, USA.

- Instagram https://www.instagram.com/reel/Co4byMWhAjx/?igshid=MTc4MmM1YmI2Ng

- https://youtu.be/p4IoOa_SMUE?si=0B744jN61rY6k9Qc