An Interview with Dr. Mangesh D Teli, Professor at the Institute of Chemical Technology

1.Share your Education and Professional Journey:

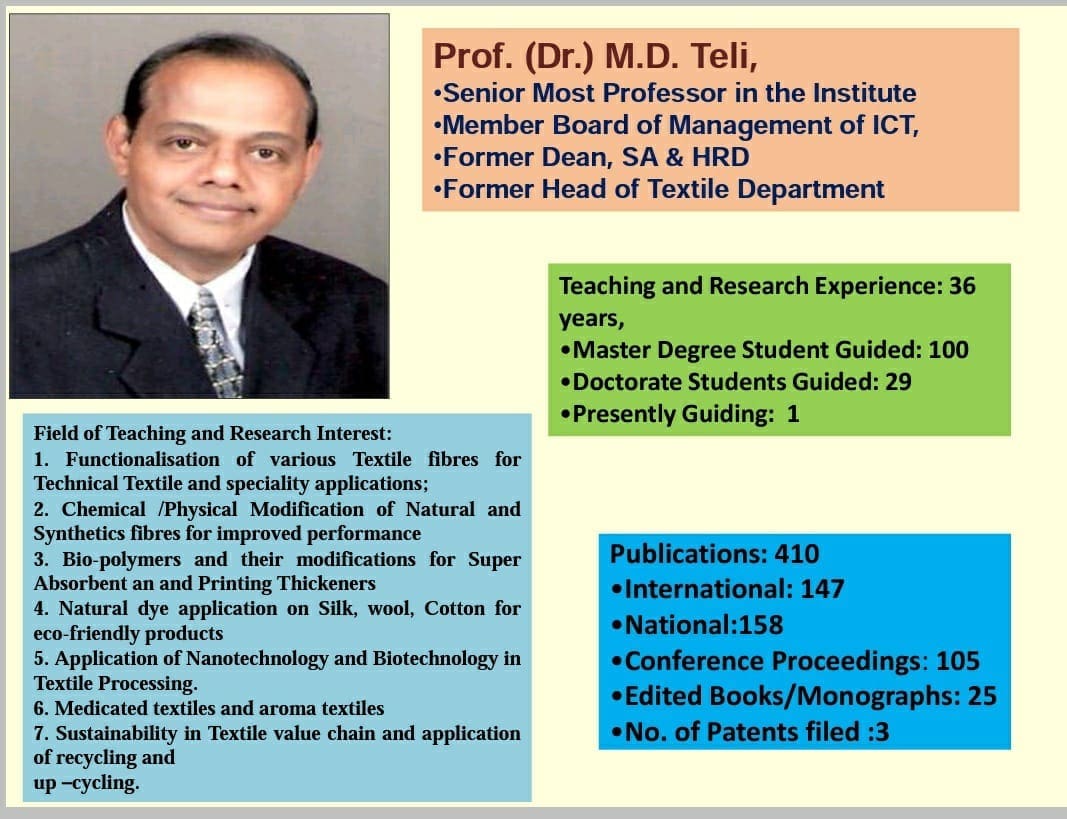

I joined then UDCT, in 1973 as a BSc.Tech student of Textile chemistry, and topped the University three times among all Branches of Chemical Technology at BSc Tech as well as MSc.Tech degrees. I was a recipient of several scholarships and then was inducted in UDCT, as an Associate Lecturer in 1978. In 1981 I finished my Ph.D.Tech and was absorbed as a Lecturer which is now known as Assistant Professor. I was fortunate to get Associate Professorship in 1986 and I superseded my seniors during that time.Relatively at a very young age, I became Professor of Fibres Science in 1991 and then in 1996 as Professor of Textile Chemistry. It means the highest position in academic excellence was achieved by me in the year 1991. It also indicates that since then technically there was no special promotion, but the simple increment in salary. And on 31st July 2017, I retired from the now known Institute of Chemical Technology, an independent Deemed University.

So my teaching and research journey has been for 39 years.Till today I have one final Ph.D. Student. Till December 2018, ie.1 year after my retirement, I taught in ICT as an honorary Professor. Because salary never motivated me to serve in ICT. Had it been so I would have never remained in this noble Profession, as till 2006, our salaries were very much limited and always invariably my Ph.D. Tech students drew their first salary at least 50% more than mine, having put in more than three decades of excellent service. I love teaching and research as it allows me not only to lecture and guide the students but interact with them and enable them to learn various life lessons from me besides Technology.

Many of my students who are now having top positions in the Industry and academia remember me for molding their ethical commitment and sensitivity to the social commitment and human values.Many of the communication skills and gems of knowledge have been shared with them from time to time by quizzing them. Application of those lessons was always tested by me during lecturing and thus it was always a different kind of teacher-student discourse when I would lecture them.

There was an unwritten principle-Laxman Rekha I had drawn for myself,

that is when “my today become same as tomorrow”, with no excitement in the job, I will quit my Institute.And that day is still not dawned. I have retired honorably, but have not quit Teaching, nor research as friends always keep seeking my assistance, and I too, keep in constant touch with ICT. Fortunately, almost every single Faculty of Textile Department has been one time or the other, my student, and that gives me the honor and also additional affection to contribute to its success. I always believed that true teachers should empower students and create in them thirst and capacity for application of knowledge, rather than spoon-feeding them with answers. And thus I had to go beyond the curriculum which I used to lecture on and relate so many life experiences to them so that they understand the true meaning of building the right attitudes and capacity.

That is why, I always wanted to be abreast of the latest technology, so that I can earn that respect from the students, my peers, and from the Industry for my academic excellence.I am happy to say that I have been always up-to-date with my lecturing and research and my output in terms of M Tech and Ph.D. Students has been around 150, research publications around 350 with additional 100 conference presentations at more than 30 Universities in different countries and about 30 edited books of proceedings as well as around 10 Chapters in various books and 5 patents.

Can’t say everything in such a small space, about the journey of a lifetime; But suffice is to say, in general as one progresses from Assistant Professor to Associate Professor to finally Poressor, his/her initial progress curve gets slowly tapered down losing its steepness slowly. I never allowed this to happen when I became Professor in the early 90s and am happy to say that in the last 5years till I retired, I had 95 publications. So when you have academic and research excellent criteria met, then the outcome is the academic and research community respects you, and naturally, recognitions from different quarters do come in your way.

Simultaneously I was practicing Baha’i Faith since 1971, and having had belief in One God, Oneness of Mankind, and Foundation of all religion as one. I followed Vasudhaiva Kutumbakam’s philosophy in my life. Hence whosoever came in contact with me, they attracted me as an iron piece does to the magnet. We both, myself and my wife in our free time would hold value education workshops and motivation workshops all over the country for PG students, faculty, young parents, directors of various departments and Institutions, college teachers, etc. I strongly believed that technology needs to go hand in hand with ethics for it to become sustainable and I used this rightful position of mine to draw the attention of my students, faculty as well as in the Industrial seminars, the role of social commitment, and ethical values. It is now becoming increasingly evident to see how interdependent we are, in this Covid-19 pandemic situation in the Globe.

So, in the end, I would say after being Head of Textile Department for 10 years, I moved to become Dean, (HRD & Students Affairs), then a member of the Board of Management of ICT, and also being senior most Professor of ICT, I officiated several times as the Acting Director/ViceChancellor in the absence of VC. So in short, the Journey at the Institute of Chemical Technology has been fulfilling and gives me a sense of achievement, that I was able to make my significant contribution to the growth of this Institute of International repute.

2- Being an educationist, your journey in industry life!

I opted for the teaching job by my choice when there was an option to go to the Industry as I was First Class First in BSc.Tech and at MScTech degrees and had Ph.D. Tech in the shortest possible time, on Synthetic Fibre Modification. I wanted to shape the careers of several students rather than enrich myself with material means, and thus as a Baha’i, I wanted to be that kind of teacher who is an enabler and inspirer. I am happy that students of mine put me in that super-category of a teacher who inspires them and shows them how to apply and use the knowledge and how to live this life long learning process.

I always learn while I teach; it’s a mutual learning process. So even in the Industry, my approach has been that of a learner who tries to know every single detail; the one who would ask to repeat the problem and then would offer a solution. In UDCT and now ICT, there has been freedom for the Faculty to do Industrial consultation/Industrial projects/special assignments against Technical consultation Fees, and 2/3 of the same would go to the faculty whereas 1/3 will be for the Institute. This way many teachers-active researchers and industrial consultants earned the revenue for the Institute sometimes more than the salary they would receive in that year.

I had kept a legitimate balance so that I had sufficient time for teaching, research as well as for Industry and Textile Association in addition to my Activities relating to motivation and personality development of youths. However, I had a series of the International and National companies on my list to whom I gave my technical inputs at some point of time in different roles- as a full-fledged technical consultant or for technical assignment/research project/expert opinion/technical magazine advisory Board, etc. To name a few Degussa Hulls(USA), Maiji(Japan), Huntsman International, Clariant, L’oreal, Procter and Gamble, Century Textiles, Century Rayon, Sarex overseas, Resil Chemicals, Elkay Polymers, Rossari Biotech, Larsen and Toubro, Ministry of Textiles and many more.

I had been on the Board of Directors of Sarex Overseas, and an Independent Director on Siyaram Silk Mills for more than 12 years.

I am happy that industry too, assisted me while raising the fund for the development of my Textile Department and they were quite happy to offer this lending hand in my efforts to develop this Textile department with which ICT was first established in 1934 as UDCT with the Mill Owners’ initiative. I must thank M/s. Reliance industries and specially Mr.Mukesh Ambani and Mr. Nikhil Meswani, Rameshji Podar of Siyaram’s and almost all the specialty and dyestuff industry heads who contributed to our success. Under my Chairmanship, we had the Annual Conference of Society of Dyers and Colorists in Hotel Taj Mahal Palace and the title of their annual conference Colour Trends was coined by me. Even ICT’s conference Tex Summit was initiated by me and we had very successful four Summits of that kind till today. We also had a very successful three year International Project with the Ethiopian Government and its Textile Body; Ethiopian Textile Industry Development Institute. Through this project of US$ 2 million, we had an opportunity to do handholding of ETIDI Technicians and give quality service and training on the shop floor in solving Industrial problems in their Textile Mills. We also helped their 15 technicians to do an M. Tech degree in ICT and one of them also did Ph. D. under my guidance. Ethiopian Ministers and the Government consider this International project as the most successful projects they have so far run. It also means ICT has 15 Ethiopian alumni living in that country who are our real ambassadors.

Unless we had in the faculty, an element of social responsibility inculcated, we would not have gone for this project, especially when that country had many problems such as Ebola, Emergency, unrest, and economic challenges. However, I am happy to say that all of my colleagues supported this move of ours because they strongly believed in their social commitment while applying technological solutions. Ethiopia needed us and we delivered it successfully.

3- As a Mentor, what qualities, capabilities you choose in your Ph. D. students?

Firstly, the ability to put in hard work, reliability, integrity, honesty in doing literature survey, and reporting results. Their reliability in doing the work and reporting the proper results matters a lot and thus integrity, loyalty, ethical commitment, etc are all also equally important. Original thinking, compatibility with other colleagues, and attitude of humility and cooperation are the traits one should possess. The killing spirit of getting the work done come what may is required rather than every time giving excuses about how certain things were not possible to do. In the sense, instead of having the habit of why things have not been done, an attitude of reporting how those things can be done is more welcoming. This way they work on problem-solving rather than nurturing the habit of getting spoon-fed. They should be good communicators, presenters and in the end, should develop an ability to undertake independent research. They should also develop the ability to handle juniors with a spirit of accompaniment and encouragement.

4.What kind of changes the chemical and dyes industry has undergone in recent years?

Indeed with increasing consciousness of sustainability requirements, the chemical and dyes industry has undergone tremendous change. Right from the German ban on Azo dyes which were responsible for the release of potentially carcinogenic amines, we have come a long way. The whole industry got itself geared to adhere to the requirements of the dyes which were free from such amines if they were to export their goods to European countries and the USA. Every country which was involved in the manufacturing of processed goods had the responsibility to see that they use safe dyes as well as chemicals. This naturally was also forced by the demands by the brands and thus eventually society stood benefited, although there was strong criticism that it may be one more tariff barrier by the developed world.

India established several Eco-testing laboratories to test such dyes and also the chemicals and auxiliaries which were non-eco friendly. This not only led to the establishment of good work practices but also gave a guarantee to the processors that supplied dyes and chemicals adhered to the standards required to be complied with.

Replacement of kerosene in

pigment printing using synthetic thickeners, use of enzymes in desizing, scouring as well a in certain cases in bleaching, also use of hydrogen peroxide instead of sodium hypochlorite, replacement of pentachlorophenol as preservatives in gums and many more such substitutes were invented. Some of the finishing chemicals including formaldehyde-based finishing agents were also replaced by polycarboxylic acids. In the case of reactive dyes, a large amount of salt was required to be used to enhance their exhaustion. Such dyes were replaced by High Exhaustion and Medium Exhaustion dyes. Not only did they require a very little salt as they contained birecative systems, but also there was a very little unexhausted dye remaining in the effluent and thus load on effluent treatment was much reduced. There were many techniques developed eg. reactive dyes can be exhausted on the cotton fabric by cationization which enhances exhaustion without the use of salt and it is then followed by fixation.

- Is sustainable fashion/ Sustainability affecting chemical and dyes industry?

Indeed sustainability is affecting the chemicals and dyes. Let me be frank, if we in reality and true to the spirit of sustainability, wish to carry out our business practices, then all that is required to be done has to be first committed by the management. Sustainability needs the organization to be financially sustainable, but that is one of the three elements. What about the social accountability of the business enterprise as well as environmental compliance? The enterprise has to accordingly follow the practices which will take into consideration workers’ and all other stakeholders’ rights and also see that the environment is least harmed.

Hence efforts towards a replacement of objectionable chemicals and dyes in the industry as well as conservation of energy, saving of water, application of renewable resources /energy, etc are being employed. Naturally, such demands of sustainability have already set in motion various research and development activities so that newer and safer chemicals, dyes, and technologies are made available and eco-friendly processing of textiles can be made possible. The reuse of energy, zero liquid discharge concepts, etc are the off-shoots of all these demands of sustainability. Good work practices at the shop floor, fair wages, avoidance of child labor, pollution control norms and waste utilization,etc are thus given a lot of importance. The stress is not just on consumption, but to look at the whole life cycle of the garment and accordingly, sustainable fashion should gear itself.

For example instead of having multiple hues from different classes of dyes to colour multiple fiber components in the same garment, if the fashion designer is conscious of sustainability and its technological requirements, with due interaction with the fiber scientists and textile manufacturing personnel, it is possible the optimum number of fibres in Optimus proportion could be made use of. Similarly, dyes of only a limited number of chemical classes can be used. In such cases, the coloration technology becomes relatively simple, effluent treatment becomes easier, and3 subsequent disposal of the garment even after its working life becomes much easier. Sustainable fashion thus has to give rise to the responsible fashion.

A simple example is the use of Natural colours on some natural fibres using nonmetallic mordants. Once you respect the concept of eco-friendliness, you do not necessarily expect too many bright colours except in certain hues as you know there are limitations to produce them. But one is happy and content having a fully eco-friendly garment, rather than the one which is not at all sensitive to the requirements of sustainability. The point I want to make here is, just after this Covid19, the world which thought we can not go slow and fastest-moving is the best, has come to the terms that in totality, if we have to be successful, we must slow down and take care of the things which we are missing out and never thought them important.

Today, health, hygiene, cleanliness, social distancing, etc have become important under the compulsion and fright that otherwise we could get infected by Covid19. But post this event, we should at least learn from such incidents and sort out our health systems, medicine availability, and overall hygiene. I feel sorry sometimes when I hear that PPE and Masks are in short supply and medical professionals are also not getting enough of them. Why is it so? It does not need great rocket science to manufacture, but just because before that it was not considered to be in demand and a profit spinner, we neglected such manufacturing of such low-value items. I think we shall soon have to look into our capability of manufacturing in India-Make in India spirit so that in an emergency we don’t have to depend upon other countries for the supply of such items.

6- What are the latest trends in the industry?

In the research a lot of new trends you will find being introduced and have the potential to be developed at the shop floor level. Industry wants to respond to fashion demands as quickly as possible and thus turn around time of fashion trend is shortening to bear minimum. It demands Right First Time and right every time, preparation without any defects, ability to provide in large orders, best of quality and many times competitive edge in terms of specialty finishes; such as flame retardant, antibacterial, stain-resistant,oil repellent, wrinkle resistance, dimensionally stable types of finishes, etc. There are still specific applications where additional demands are there from the industry. Bulletproof material, parachute clothing, high altitude clothing,chemical and heat resistant clothing, etc. Textiles required in the Medical field, such as PPE, gloves, masks, aprons, and all of them with specific standards are required. Textiles are required in many technical textile fields such as automobiles, in construction fields, agriculture and horticulture, and so on in addition to the apparel and sports wears and home furnishing which is commonly known to all of us.

Newer finishes and chemical formulations based on nanotechnology and biotechnology are being welcomed. Digital printing, 3 D Printing, waterless dyeing, plasma application, ultrasound technology, transfer printing, etc are also looked at as the alternative models to make the processing more sustainable and eco friendly.

So the industry needs such products with durable quality, very good performance properties, processed eco-friendly way, and also competitive in price so that they are affordable too.

7- Any update on Carbon Footprints and its relevance to the industry?

Sustainability, as I mentioned, is going to drive the agenda of future manufacturing and consumption. The business as usual practices which are characterized by total disregard to environment and social accountability and which

only revolve around profitability are

no longer going to be welcomed. The realization of the importance of environmental protection is at the highest level at present and thus sooner than later, the Carbon footprints of the products will be looked into by the brands and the consumers. Just as at present,we see the ingredients of food items on the packet along with their percentage and calories they offer, similarly the need for a declaration of Carbon footprints of various products including Textile apparel will be widely advocated. It is then the true spirit of the Kyoto protocol accepted by more than 150 countries a few decades ago will be revealed. There is already talk about what are the Carbon footprints of such products and water footprints; in fact, many times debate goes on about 1 kg Cotton garment requiring about 200 liters of water and so on.The same is in terms of CO2 emission. Indeed we are in an alarming situation and we have already consumed more than 30% of earth resources and if we don’t change our methods of manufacturing and style consumption, we would need another planet by 2050. The life of our future generation will become highly unsustainable. The Present crisis itself gives us how fragile our life has become, although we might call us “mighty and powerful” countries with the highest level of technological development.

Hence, before we are compelled to do it, and at that instance, we may not have sufficient time, we must become conscious of sustainability and ask for the products which are eco friendly and have the least Carbon footprints. Such products will get more premium in the market and it will prove that marching on the path of sustainability makes true business sense. which will bring in true prosperity providing a win-win situation for all the supply chain partners.