Sanathan Textiles, a global supplier of cotton yarns, polyester yarns and yarns for technical textiles, has three yarn business verticals giving the company the unique opportunity to offer a wide variety of yarns that are used by various sectors and industries, across applications and end-uses. Having a technologically advanced and environmentally conscious manufacturing setup enables us to offer customers value-added yarns, niche yarns, functional yarns and a wide range of coloured yarns.

Promoted by the Dattani family with 100+ years of cumulative experience in the yarn industry and managed by a professional and experienced team, Sanathan Textiles is committed to its aim of providing value added innovative yarns for the fabric of our lives. Mr. Paresh Dattani is the Managing Director of the company.

Mr.Sammir Dattani, Executive Director of Sanathan Textiles replied to the Textile Value Chain’s Questionnaire.

Excerpts:

Your company seems to be a leading firm in yarns. When did the journey begin and what is the progress till now?

As a family we have been in the yarn business for 75 years. Over the years Sanathan textiles has expanded manufacturing into 3 yarn businesses/segments namely – polyester filament yarns (PFY), cotton yarns and yarns for technical textiles.

Our key focus has been on the yarn segment of the textile chain since its the base of the entire textile eco-system. We have the opportunity to supply our products to many industries, sectors and end-uses. In the last 5 years we have seen the yarn business in PFY evolving a lot making it a very exciting space with ample opportunity for innovation and value addition.

How was the functioning during the severe stages of the pandemic?

Initially we were all affected due to the lock down restrictions because of COVID, but once production resumed in June 2020, things only improved every month. The demand due to China +1 factor has been very strong from customers around the world, enhancing export demand for all textile products from India.

What about the venture into technical textiles?Give us a glimpse.

Started in the year 2017-2018, our division of Yarns for Technical textile & Industrial uses, has been equipped with the most advanced manufacturing setup, designed and delivered by Oerlikon Barmag Germany offering high tenacity yarns which are used for a wide variety of applications, from 600 to 6000 denier. Technical and Industrial use yarns are deemed to be the highest discipline in filament manufacturing and can pose a significant challenge for the manufacturers. However, our expert and professional team tackle these challenges to create the best technical and industrial yarns for our customers.

Regular Shrinkage, Low Shrinkage, Super Low Shrinkage, BornDyed™ Coloured Yarns for Technical Textile are some of our product offerings.

What are the brands you have developed and what are their USPs and benefits for the users?

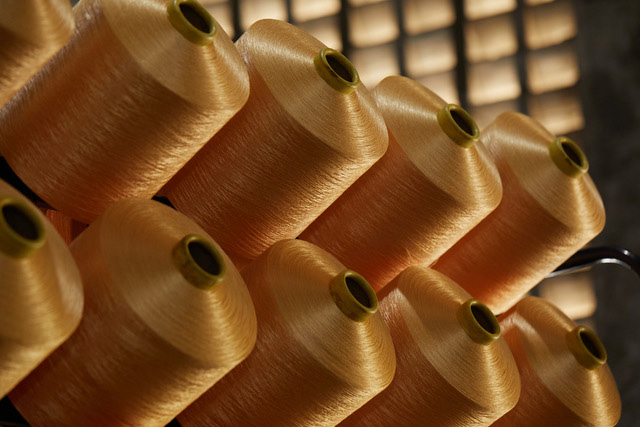

We have started marketing a lot of our value added yarns, like performance yarns and functional yarns, under the “Sanathan” brand for better marketing, product differentiation and customer recall. Some of the branded products we currently offer are mentioned below –BornDyed™ – Our rage of eco-friendly coloured yarns.

We offer a large variety of shades and colours. We also offer customized, Made to Order colours #OurYarn- YourColour

Sanathan Stretch™ – Yarns which add freedom of motion and movement to the garments. Sanathan DryCool™ Yarns – innovative polyester yarns designed with moisture-wicking properties to keep you cool and dry.

Sanathan Reviro™ – our range of GRS certified Re-cycled yarns made from waste PET bottles. Helping you make responsible choices.

Above are some of our current brands. We are continuously developing innovative yarns to strengthen our product portfolio which will be in sync with the customer demands.

Other than yarns, what are the new plans for the future?

The yarn manufacturing space is going through a very exciting phase, currently our focus is completely on our yarn business and we have our hands full with the same at the moment.

What is your set-up in infrastructure and R&D?

Our current plant located in DNH (Dadra and Nagar Haveli) produces three yarn segments – polyester, cotton & technical textiles. It is an integrated setup providing customers a one stop shop for a wide variety of yarn requirements. We have equipment designed and supplied by global leaders in the yarn manufacturing industry – Oerlikon Barmag, Reiter, LMW, TMT Japan, Aiki, Alidhra. Our setup is abled with the appropriate amount of automation and technology to enable our team with better and more consistent performance.

• Our plant provides automatic doffing, transportation and package handling systems to meet global inventory management standards.

• We also have automated warehouse management system to ensure high efficiency, less damage and better inventory management in a limited space-We have a dedicated and skilled team for process management, quality control and research & development.

Focusing on developing new yarns to carter to varied end use and applications across multiple industries. Our experienced team is focussed on this endeavour to ensure we be ahead of the curve in making high value- added yarn products. We achieve the above by focusing on the below

• Updating our lab facility with the latest equipment

• Constant product benchmarking

• Finding the problem and then working a solution

• Understanding the customer’s purpose and desire

What is your wish-list for the industry and the Government?

Our government has been very proactive and supportive to the textile industry. Announcements such as the PLI scheme and the recent Textile Technology Development Scheme (TTDS) have created lots of excitement and growth prospect for the industry. The world is looking at an alternative supplier to China. The textile industry has seen tremendous demand

boost from around the world due to the China +1 factor and now with the right government initiatives and support, India can surely reap the benefits. Locally the inverted GST structure is a hurdle for MMF manufactures which the ministry is aware of. Some prompt and amicable solution for the entire industry is expected soon.

Views on Sustainability, Recycling, Waste management Sustainability is at the heart of every decision we make at Sanathan Textiles. Whether its regarding business,people, or our surrounding. With the second generation fully involved in the running of the business at Sanathan Textiles, we are aware of the importance of climate change and are keen to introduce measures to help reduce our carbon footprint as an organization.

– Keeping in sync with these ethos we installed a 2.3MW solar power facility for in-house supply of renewable power.

– We recently converted all our packaging carton to FSC paper.

– We have already installed Solutions at our facility for systematic disposal of waste.

Our foray into BornDyed™️ coloured yarns, which uses dope dyed technology to produce colour polyester yarn is an eco-friendly solution to producing coloured yarns.

Reducing consumption of chemicals and shortening the supply chain helps in reduced production costs and ensures the ecological footprint of the final products is in check.

As the demand for sustainable textile increases, we at Sanathan have decided to contribute by producing yarn from PET chips which are made from waste recycled bottles. With Reviro our endeavour is to contribute to the new worlds efforts through Reducing, Reusing and Recycling.

What are your future goals to increase productivity?

In 2020 we doubled our cotton yarn capacity which is in full production now. While in 2021 we increased our manufacturing capacity in Yarns for technical textiles. In the coming years we hope to grow in a similar fashion.

Recycling Fiber is the new trend in textile, what is the growth you can see in this industry?

With growing environmental concerns and awareness, recycling waste in useful textile products is the need of the hour. The demand for sustainable textile is increasing every day from our customers and brands.

At Sanathan Textiles have started our range of recycled yarns made from waste recycled bottles by converting them to PET chips. Our range of recycled yarns are marketed under our brand name Sanathan Reviro. This range of recycled yarn products are available as texturised yarns, fully drawn yarns and also come with the required GRS certification.

The demand for these yarns are going to grow at a faster pace in the coming years because of customer awareness and requirements.