Gilberto Loureiro, Co-Founder of Smartex

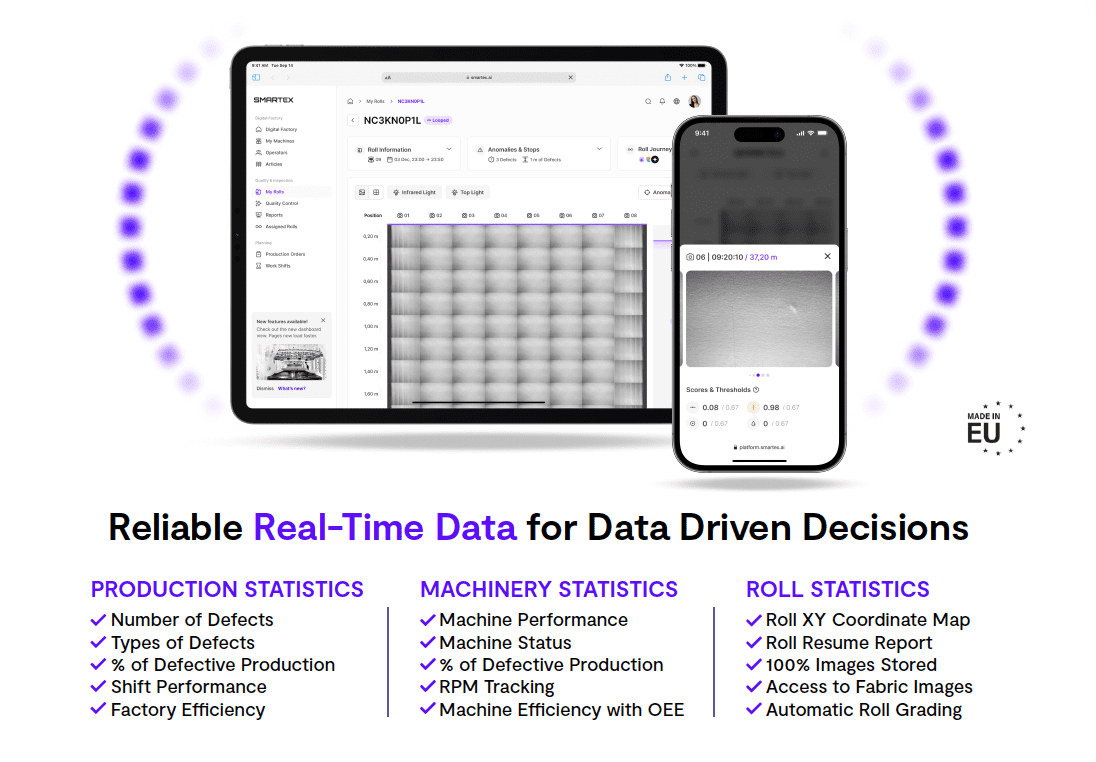

Smartex stands out as a distinguished hardware-based software company, renowned for its dedication to advancing solutions for the modern textile factory. Specialising in AI-driven technology, Smartex empowers textile manufacturers to optimise operations, enhance quality control, boost sustainability, and streamline supply chain processes. At the forefront of this revolution are Smartex CORE and Smartex LOOP, two groundbreaking tools that enable manufacturers to unlock their full potential and excel in a competitive market. Smartex CORE utilises artificial intelligence and machine learning algorithms to detect defects in Circular Knitting Machines, while Smartex LOOP revolutionises supply chain communication through fabric-roll level data collection. With a commitment to digitising the textile industry, Smartex is reshaping the future of manufacturing, striving for a zero-waste world.

Recently, at ITM 024, our TVC Media Team had the privilege of speaking with Gilberto Loureiro, Co-Founder of Smartex, who shared his passion for technology, automation, and sustainability. As a company driven by innovation and a vision for a sustainable future, Smartex is dedicated to empowering factories worldwide to produce efficiently and sustainably.

What does Smartex do? Are they in smart technology or sustainable textiles?

I am Gilberto, the co-founder and CEO of Smartex. With a background of over 15 years in textiles, my journey began in knitting and quality control due to my family’s textile legacy. The realisation of the challenges in manual fabric inspection led to the inception of Smartex. Our company specialises in creating innovative solutions using camera systems and artificial intelligence to automate fabric inspection processes and enable proactive measures within textile manufacturing. Initially founded by three co-founders with diverse expertise, Smartex has now grown to 140 engineers, primarily software experts, operating from headquarters in the US, with main offices in Europe and Turkey, and expanding into India and Bangladesh. With a growing clientele and continuous technological advancements, Smartex is revolutionising the textile industry with cutting-edge solutions for efficient and proactive fabric inspection.

What drew you to textiles despite the industry’s slow tech uptake?

The inspiration to venture into the textile industry was driven by the evident technological gap and inefficiencies prevalent in the sector. Observing the lack of automation and technological advancements in textile manufacturing compared to industries like automotive or electronics, the motivation stemmed from the immense potential for innovation and improvement. This era presents a unique opportunity to leverage technology, particularly artificial intelligence and machine learning, to revolutionise textile production. Additionally, personal experiences, such as childhood traumas and encountering challenges like fabric defects without proper tracking systems, fueled the development of solutions like LOOP and FACT to enhance transparency and efficiency throughout the supply chain. Ultimately, the goal is to make a significant impact by introducing cutting-edge tools and solutions that address industry-wide challenges and drive positive transformation.

Will traceability become standard in textiles, and how are brands jumping on board?

The future of traceability in the textile industry holds significant potential as a key tool for enhancing sustainability practices. Despite the current reluctance to invest in traceability due to the perceived lack of financial incentives, it is intricately linked to sustainability goals. By implementing systems like QR codes and cameras to track production processes, inefficiencies such as yarn swaps and defects can be identified and rectified, leading to improved productivity and sustainability. While the adoption of traceability tools like LOOP and CORE remains optional for fashion brands at present, the increasing demands for sustainability and transparency suggest that it may soon become a standard practice in the industry. Ultimately, traceability is poised to become an indispensable tool for driving sustainability improvements within the textile sector.

Who bears traceability costs & how does traceability software make money?

Traceability costs are ultimately borne by consumers. Our solution generates savings for manufacturers through waste reduction, enabling them to invest in traceability without increasing costs. We charge based on these savings, ensuring an ROI for our clients and no added expense for brands or consumers.

Should fashion brands invest in traceability even without legal requirements?

Traceability systems offer superior monitoring and control compared to certifications, leading to cost savings and improved efficiency. Brands should encourage suppliers to adopt these systems for mutual benefit.

How can young entrepreneurs with disruptive ideas win in a crowded industry?

To succeed as a young entrepreneur, anticipate challenges, persevere, and think boldly. Expect scepticism, but stay focused on your vision. Leverage technology to disrupt industries, invest wisely in talent and capital, and aim for global impact.