To help the person achieve the ideal temperature, a temperature-sensitive fabric adapts to how hot, cold, or perspirant they are. The yarn used to make the fabric is heat-sensitive, and its fibres respond to heat and humidity by expanding or contracting.

When the yarn is warm or wet, it compacts into a little bundle, which causes gaps to appear in the fabric, allowing heat to escape. When the material is cold or dry, the opposite happens: the fibres expand, closing holes to keep heat from escaping.

Introduction

Since ancient times, clothing has played a crucial role in human life, whether it is as a means of weather protection or as a necessary item serving a variety of social functions like adornment, identification, modesty, and prestige. If it were not for textiles, the human species would not have been able to endure and live in many regions of the earth, from the coldest spots to the most hostile ones. Textiles made it feasible for humans to travel to unexplored areas, scuba dive into the deepest oceans, scale the tallest mountains, and explore space.

For ages, textile materials’ principal function has been to provide protection from heat and cold. Textiles will continue to be important components of protective equipment due to the growing demand for human comfort and protection from heat and cold during our daily activities or employment, as well as the ongoing development of health and safety laws. Thermal protection entails enhancing human safety from the effects of heat and fire without losing comfort. In order to achieve sufficient body insulation, address the dangers of cold climes, and

achieve fundamental clothing qualities like breathability and comfort, protection against cold necessitates a variety of design solutions.

Thermal Protective Textiles

Industrial workers, firefighters, and others who are frequently exposed to hazardous settings including high temperatures and fire depend on textiles to protect them from heat and fire threats. Other needs, such comfort and durability, should also be met by thermal protection apparel. However, when it comes to heat and fire gear, protective qualities frequently come at the expense of the wearer’s comfort. When such happens, extra precautions are required, like setting a maximum wearing time.

Flame-Retardant Fibres And Textiles

Textiles and fibres that are flame-retardant are those that do not burn easily or burn slowly if they do. After the fire source has been extinguished, these materials burn for a little period of time. Flame-retardant fibres typically undergo carbonization and offer a carbonaceous coating that shields them from the ignition source.

Flame-Retardant Cotton

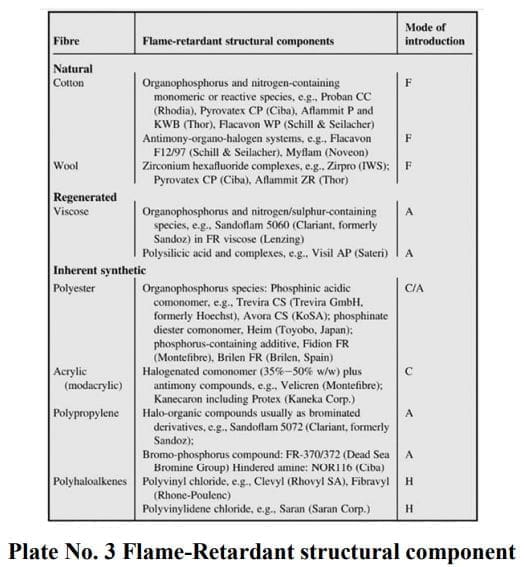

Flame-retardant cotton textiles are often made by chemically treating cotton fibers, and they offer acceptable flame-retardance qualities at a cheap cost for common use.

Flame-Retardant Wool

The maximum nonflammability among conventional fibres is what makes wool unique. Complexes of zirconium hexafluoride are added as a finishing component to the dye bath. (Plate No.3)

Flame-Retardant Viscose

When producing viscose fiber, flame-retardant components are typically added into the spinning dope. This is accomplished through the use of polysilicon acid and complexes, organophosphorus, and compounds containing nitrogen and sulphur as additions during the manufacturing of fibre. (Plate No.3)

Flame-Retardant Synthetic Fibres

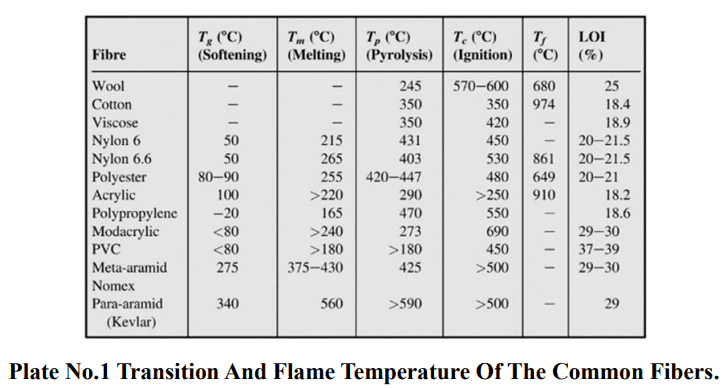

For flame-retardant textiles, synthetic fibres are not suitable since they rapidly melt at temperatures over 250oC. They can, however, be used sparingly in blends with other naturally flame-resistant fibres. However, the presence of flame-retardant materials as additions in the polymer melt or by copolymeric modification can demonstrate flame retardance. Plate No. 3 presents the main synthetic fibres and flame-resistant structural elements.

Coatings

To achieve flame retardancy, coatings with flame-retardant ingredients can be applied to one or both surfaces of fabrics. Copolymers of vinyl or vinylidene chloride are typically utilised for this.

Heat And Fire-Resistant Textiles

Textiles that are heat and fire-resistant may withstand higher temperatures for an extended period of time. These fabrics constituent fibres typically have chemical structures that are hardly visible.

Thermoset Fibres

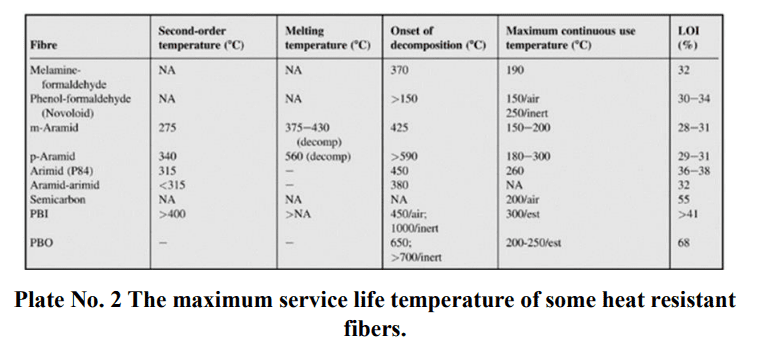

The most popular types of thermoset fibres include melamine-formaldehyde Basophil and phenol-formaldehyde Kynol. When these fibres are heated to a high temperature, they carbonise and transform into char. When in touch with fires, thermoset fibres release very little harmful gas.

Aramids And Arimids

The most well-known class of high-performance, thermally protective fibres are .aramids and arimids. The amide-CONII- or imide-CON groups that connect them to one another form repeating aromatic units.

Semicarbon

Similar to how carbon fibre is generated, semicarbon fibres are made from oxidised acrylics. Among the commercially available semi-carbon fibres are Sigrafil O, Celiox, and Grafil O (Courtaulds) , (SGL).

Fibres

Semicarbon fibres are produced from oxidized acrylics with a similar process applied for carbon fibre production. Some commercialized semi- carbon fibres include Grafil O (Courtaulds), Celiox (Celanese), Sigrafil O (SGL).

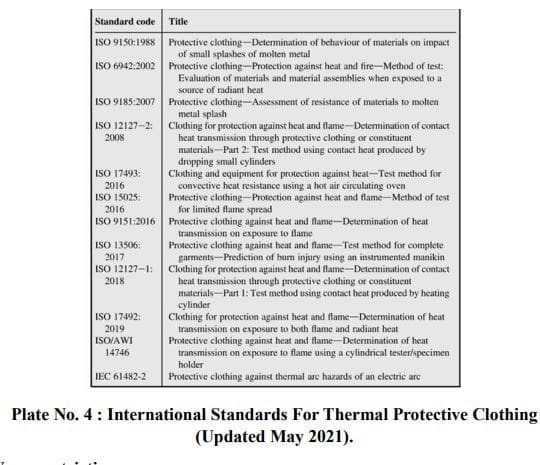

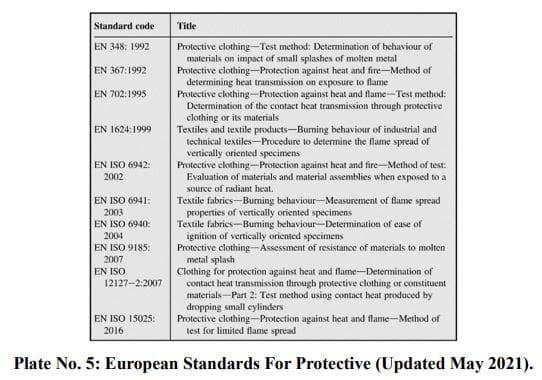

Standards And Testing Of Thermal-Resistant Textiles

Heat in the form of convection, conduction, and radiation, fires, molten metal, hot fluids, explosions, etc. are examples of thermal risks that may be present in the workplace, in contract or household settings.

Cold Protective Textiles

Body Heat Balance

Our bodies are open thermodynamic systems. Our bodies and the environment are constantly exchanging nutrients, waste products, heat, oxygen, and heat. As a result of metabolic activity, which transforms biological energy into chemical and thermal energy, heat is created. Body functions are propelled by chemical energy. Through several processes including convection, conduction, radiation, evaporation, and respiration, thermal energy is released to some amount to the environment.

Vasoconstriction:

The process of blood vessel constriction that causes the blood flow to the skin to diminish is this. The temperature difference between the body and the environment is decreased as a result of it, which also lowers skin temperature. Heat loss is thereby reduced as well.

Thermal Comfort

In general, comfort can be characterised as being at ease, pain-free, and devoid of any physically unpleasant sensations brought on by pain, heat, cold, etc. It is nearly impossible to establish an objective set of circumstances that can be used to describe what is comfortable for everyone because the experience of comfort is frequently subjective. Numerous elements, including a person’s physiological and psychological state, the physical environment, the weather, tactile senses, etc., can influence how comfortable someone feel at a given moment.

The American Society of Heating, Refrigeration, and Air Conditioning Engineers recommends that a space be maintained at a temperature range of 22.2-25.5°C for people wearing long-sleeved shirts (0.6 clo), indicating that the comfort zone where physiological temperature regulation can be achieved is very small.

Thermal Insulation

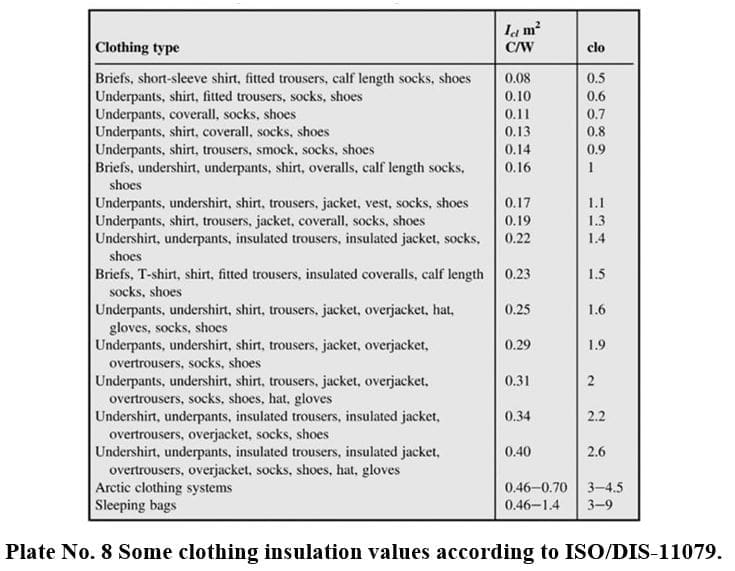

Clothing significantly affects each of the three modes of heat transfer, therefore the equations for convective radiative and evaporative heat transfer above often consider nude surfaces. Layers of clothing prevent the skin’s thermal insulation from radiating or convecting heat away by covering it (f. The value it represents is the average of the covered and uncovered bodies).

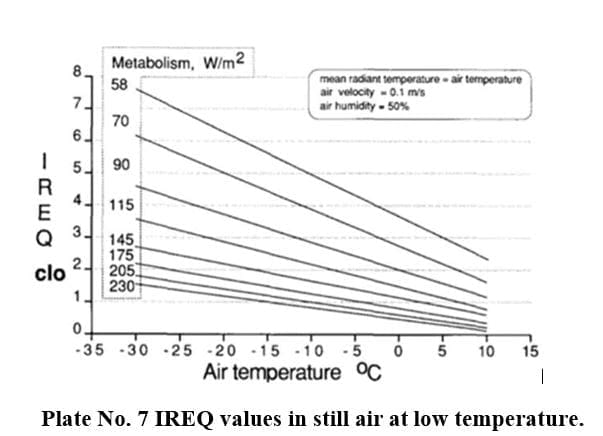

Clothing Requirements For A Cold Environment

For various activity and climate scenarios, the values for total insulation I and evaporative resistance R7 can be determined using the body heat balance equation adapted for clothes (Eq. 10.7). Cold weather protection is covered by a number of international standards, including ISO/DIS-11079, ENV-342, ENV-343, ENV- 14058, and EN-511.

The fundamental insulation value (1) discovered using thermal manikins identifies a garment’s typical insulation. Since insulation is most strongly correlated with the air trapped inside garments than with any other component, clothing design has a significant impact on insulation capacity.

Clothing Design For A Cold Environment

Human safety is seriously threatened by the cold. Cold protection apparel should be breathable and offer sufficient insulation to prevent overheating while also slowing down the loss of body heat. It thought to act as a deterrent to wind and water infiltration.

Fiber Properties

By conduction between two fibre surfaces or between the fibre surface and human skin, fibre/libre radiation, and convection of air in the fabric structure, heat can be transferred through clothes. The insulating qualities are only little impacted by the thermal conductivity and specific heat of the fibre material.

Yarn Properties

Thermal characteristics are greatly influenced by yarn type as well. The insulating characteristic of yarn has been observed to increase with yarn hairiness. More air can be trapped in yarns with projecting fibres. Due to the bulky nature of low- twist yarns, which trap more air, it should therefore be assumed that yarns with low twist will have better insulation.

Fabric Properties

Other significant aspects that need to be considered are fabric kind, construction, and design. The most crucial variables are the fabric’s structure, its surface and optical characteristics, as well as its areal weight, thickness, design, and porosity. In comparison to woven and knit fabrics, nonwoven fabrics may hold more air inside their structure.

Garment Properties

The style and fabric of the garments also influence how they insulate. A practical strategy for achieving cold-weather protection is to wear several layers of clothes. It is possible to create layers with various functions.

Moisture Management Properties

Sweating while participating in an activity and insensible perspiration at rest are the two ways that evaporative heat transfer occurs within textiles. Through the diffusion of water molecules through the air gaps between fibres and yarns, moisture can move throughout the fabric.

Smart Textiles And Chemical Finishes

It has been demonstrated that the heat management capabilities of fabrics containing phase-change polymers are significantly enhanced. These materials can be added to spinning dopes or used as finishing materials by coating, laminating, or printing. By transitioning from a solid to a liquid phase, they can absorb heat energy. They can then release the heat by going back to a solid phase.

Conclusion

For our daily needs, textiles are a necessary material. Textile materials that protect us from the many environmental risks we encounter on a daily basis while engaging in regular or professional activities are essential components for our security and comfort. The elements of heat and cold, fire, chemicals, radiation, ultraviolet light, microbes, and more are among these dangers. Since ancient times, textile materials have been primarily used to defend against heat, cold, and fire. Textiles used as furnishings, fire and heat barrier textiles, and other materials in dangerous situations are all examples of thermal protective textiles. They also include garments worn by industrial employees, firefighters, and defence people. Convective, conductive, radiating thermal energy, as well as their mixtures, must be rejected by thermally protective clothing.

References

- Donna (2019, February 7). Heat-sensitive fabric cools you on hot days and warms you in the cold. Retrieved from https://www.newscientist.com/article

- Pintu Pandit, S. S. M. (2022). Protective textiles from natural resources. Elsevier Science. (book)

- Nicola Davies. (2021, June 29). From Hot to Cold and Cold to Hot: Fabrics that Work with your Body Temperature. Retrieved from https://www.technicaltextile.net/articles/all-weather- clothing3288#:~:text=highly%20efficient%20breathable,protection%20fr om%20rain.

- Ralph (2022, January 27). US’ Ralph Lauren launches new temperature responsive fabric. Retrieved from https://www.fibre2fashion.com/news/apparel-news/us-ralph-lauren- launches-new-temperature-responsive-fabric-278609- newsdetails.htm#:~:text=Leading%20fashion%20brand,to%20Ralph%20 Laure.