- A technical textile is a textile product designed for non-aesthetic objectives, with utility being the primary consideration.

- Textiles for automotive applications, medical textiles (such as implants), geotextiles (for strengthening embankments), agrotextiles (for crop protection), and protective apparel are all examples of technical textiles. (e.g., heat and radiation protection for fire fighter clothing, molten metal protection for welders, stab protection and bulletproof vests, and spacesuits).

- The advanced technical textile sector offers material solutions to a wide range of niche industries by combining science, information technology, and specialised materials.

- Advanced Textiles Develop Materials with Better Performance, Structure, and Strength Utilizing New Concepts and Methods.

Innovative advanced textiles [1]

- The usefulness, usability, and product distinction of parts are increased by new materials.

- The industry sets itself apart from the traditional textile industry by implementing novel concepts and procedures to produce materials that adhere to particular specifications.

- Innovative advanced textiles may enhance consumer goods at a low cost while adding exceptional features. They are typically used for performance, structure, and strength.

Revolution of the Textile Industry

- Conventional Textile

- Main Uses – Protection, Comfort, Decoration

- Labor – Intensive

- Low Automatization

- Low R and D Investments

- Few Categories of application (low Flexibility)

- Advanced Textile

- Main Uses – Specific Scope and Functional Properties

- Capital – Intensive

- High Automatization

- Massive R and D Investments

- Plenty Categories of application (High Flexibility)

Advanced textiles experiencing fast growth

- The Industrial Fabrics Association International (IFAI), a trade organisation that speaks for the global specialised fabrics market, estimates that the market for advanced textiles will expand overall by roughly 9% and is presently worth $71 billion.

- Protective textiles make up 6% of this industry’s output, while high-performance apparel, composites, coated textiles, and smart textiles are all significant contributors.

- Graphite, Vectran TM, Teflon TM, Dyneema®, and Spectra® fabrics, as well as composites or other specialty fibers, are typical examples of high tech/specialty fibres with properties designed to bring added value and increased performance to the end use application.

- Bally Ribbon Mills (BRM) has discovered that consumers want to stand out from their rivals by using cutting-edge fabrics. They seek to extend the lifespan of their product, make it lighter, or offer it other qualities that will give them a competitive edge. Advanced fabrics are being utilised to make items stronger in the personal protection sector. One BRM customer, for instance, sought to get rid of belt elongation in a production process. The belt was able to keep its integrity for 10 times longer than the previous iteration by adding low elongation para-aramid and UHMWPE fibres to the original substrate.

- In recent years, there has been a drive for textiles that are lighter, stronger, and enable people to accomplish more with less. Although there are many different uses for advanced textiles, the most cutting-edge technical textiles would or should be used in industries that enhance quality of life. This could include military, industrial, and medical uses for parachutes as well as certain industrial and industrial ones. By industry, they are seeking for different kinds of features. While the medical sector looks for materials that are less intrusive and encourage faster recovery, some people still seek out stronger and lighter textiles.

- It should be mentioned that even for items that have been on the market for decades, different markets are searching for innovation and developments. A design review might still be beneficial for something even if it has been in use for a while. For instance, BRM has improved the design of dog collars to make them more durable. Customers want to stand out from the millions of other businesses producing canine items (and baby things!) in sophisticated design. Sun awnings are another excellent illustration of the usage of cutting-edge fibres in well-established items. Manufacturers are coming up with new techniques to weave fibres that wear better and can last 50 years instead of 10. Advanced textiles may be used anywhere manufacturers are looking for a competitive advantage.

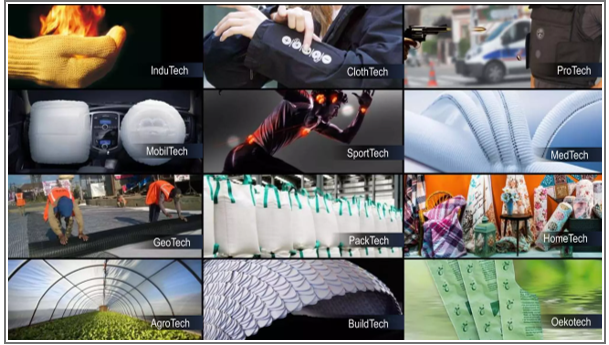

Applications of Advanced Textile

Different Types of Advanced Textile [7]

- Indutech (industrial textiles)

- Mobiltech (textiles used in transport; automotive and aerospace

- Geotech (geotextiles)

- Agrotech (agro-textiles)

- Clothtech (clothing textiles)

- Sportech

- Packtech (packaging textiles)

- Buildtech (construction textiles)

- Protech (protective textiles)

- Meditech (medical textiles)

- Hometech (domestic textiles)

- Oekotech or Ecotech (ecological protection textile) [7]

Electronics in textiles

When textiles and electronics are combined, technology is made possible for many uses in the medical field, rehabilitation, and sports. Larger functions and contextual capabilities for wearable computers include sensing, adaption, resource finding, and augmentation.

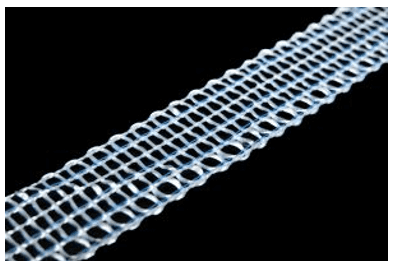

E-WEBBINGS enable electronic transmission of data, sensations and power [1]

Examples of the newest advanced textiles include:

E-WEBBINGS® are conductive, narrow-woven textiles that may be stored or utilised to actuate or modify things. They allow the electrical transmission of data, sensations (light, noise, vibrations, and heat). Together with other fibers, these special conductive fibres may be weaved to create embedded sensors for wearable and embedded electronics, such as the Internet of Things.

One brand-new concept now under development makes use of sophisticated weaving techniques to combine fibre-optic filaments with high-performance structural materials. The organised result of the weaving process is optical “carriers,” which are used to build assemblies that can collect and transfer data to computer equipment farther down the line. The optical technology can support the integration of non-destructive inspection equipment, the optimisation of production processes, and the taking of remedial action based on better monitoring capabilities. [1]

TPCM™ woven thermoplastic localized reinforcements

These thermoplastic composite materials are woven thermoplastic structures that are either 2-D or 3-D for inclusion into composite components created using a variety of dynamic moulding techniques. Several sectors, including aerospace/aviation, automotive/transportation, military, architecture/infrastructure, marine, and sports/recreation, utilise hybrid composite constructions that incorporate woven structural forms.

Structured and matrix/resin fibres are used to make TPCM textiles, which are orientated to maximise X, Y, and/or Z directional characteristics. They can manufacture higher-quality, lighter-weight components with lower labour and material expenses, as well as simpler processes and material bills. A variety of structural yarns (such as fiberglass, carbon, and aramid) and matrix/resin yarns are possible fibre combinations. (such as PE, PA6, PEI, PPS and PEEK). Where better characteristics are needed, TPCM with a tailored and designed weave pattern offers targeted reinforcement.

As part of a joint development project, BRM is working with suppliers and downstream fabricators to enhance TPCM textiles. One partner in the initiative is Concordia Fibers in Coventry, Rhode Island, which provides Comingled Yarns. Its method generates a superior mixture of structural and matrix yarns, which enhances the woven structures’ characteristics. Customers that purchase this kind of fabric have access to comprehensive supply chain expertise, covering the full process and product development process. The most innovative strategy for collaborating with suppliers to guarantee product success is this one.

With less complicated manufacturing processes and bills of materials, TPCM textiles can deliver lighter-weight, high-quality components for lower material and labour costs. [1]

NFC Interactive Clothing

The creation of the Internet has simplified and made daily living easier. The Internet of Things (IOT), where numerous systems and gadgets are connected to use data everywhere, anytime, is a new Internet revolution. Over the upcoming years, IOT is anticipated to grow quickly. This convergence and drive will release a new dimension of services, enhancing the standard of living. Although IOT has penetrated all significant industrial sectors, the textile industry is one where it has not yet done so. The ‘Interactive clothing’ system is the one that has been proposed, and it uses IOT and NFC tags. A unique ID is contained in an NFC tag that is sewn into the clothing. Both manufacturers and end users will benefit from the digital environment created by the mobile application, which scans the NFC tag embedded in the fabric and connects to a cloud-based database. It also aids in monitoring use patterns. [3]

Colour Changing Fabrics

The invisible, a London-based design firm, has created chameleon-like apparel that makes standard heat-activated, colour-changing t-shirts appear to be high school science fair projects. Specialized cloth in the fashion project, a couture capsule collection dubbed “air,” changes colour when exposed to wind and other stimuli. The fabric adapts and alters its look in response to environmental conditions such as wind, UV radiation, moisture, and four other elements thanks to the material’s integration of nano compounds, chemical technologies, and inks and dyes.

varied stimuli have varied effects on the cloth. According to Design Boom, “Pollution can only travel back and forth, from yellow to black, but heat alters colour in RGB and pantone irrevocably.

The outfit even resembles a dragon’s or an exotic bird’s hide or armor, with its iridescent façade. “Air” is “intended to reveal the otherwise unseen turbulence surrounding the human as it moves about its environment,” according to THE invisible. On a warm, bright day, the collection must be absolutely stunning, but the thought of how it might fare in a hurricane sends the mind reeling. [4]

Self-Healing Material

A type of intelligent material known as self-healing material has the capacity to repair structural flaws on its own. This power may fix harm that a machine sustained from repeated use. [5]

Benefits of Advanced Textiles

Advanced textiles can contribute exceptional qualities including lower weight, particular strength, durability, stability, abrasion resistance, and sustainability while increasing a part’s usefulness, utility, and product distinctiveness at a competitive net cost. BRM stands apart from the competition due to its exceptional capacity to create high-tech textiles via creativity, experience, design, research, development, quality, technological breakthroughs, and customer service. [1]

References

- Davis, R. (2020, April 24). Rachael Davis. Textile World. Retrieved February 16, 2023, from https://www.textileworld.com/textile-world/nonwovens-technical-textiles/2020/04/advanced-textiles-use-new-ideas-and-processes-to-create-materials-that-improve-performance-structure-and-strength/

- Wikimedia Foundation. (2023, February 11). Technical textile. Wikipedia. Retrieved February 16, 2023, from https://en.wikipedia.org/wiki/Technical_textile#External_links

- Outdoor clothing brand uses NFC technology to Digitise Products. Spring wise. (2019, October 31). Retrieved February 16, 2023, from https://www.springwise.com/outdoor-clothing-connects-to-its-own-app/

- Wind-reactive fabrics change color like a chameleon. VICE. (2014, July 25). Retrieved February 16, 2023, from https://www.vice.com/en/article/bmyz93/wind-reactive-fabrics-change-color-like-chameleon-skin

- (2022, June 17). Self-healing material. YouTube. Retrieved February 16, 2023, from https://www.youtube.com/watch?v=DAUl6upA3q4

- E-WEBBINGS® smart textiles & fabrics. Bally Ribbon Mills. (2020, August 5). Retrieved February 16, 2023, from https://www.ballyribbon.com/products/e-textiles/

- Matteo Carbone (n.d.). Advanced textiles. Share and Discover Knowledge on SlideShare. Retrieved April 10, 2023, from https://www.slideshare.net/MatteoCarbone5/advanced-textiles