Unique processing of NASA insulation on a textile medium

Comprised of up to 99.8 percent air, aerogel is the lightest solid in the world. But that is not all. The material, which is also called “frozen smoke” due to its appearance and physical properties, exhibits extremely low heat conductivity which exceeds other insulations many times over. This is why NASA has already been using aerogel for aerospace projects for many years. Despite this, it has not been possible to bind the material to textiles in a high concentration and enable straightforward further processing over the roughly 90-year history of the material…until now. Outlast Technologies GmbH has developed an innovative process for permanently adhering large amounts of aerogel to different media, like nonwoven fabric, felt and composites materials. Their original properties are retained throughout, so they can easily be further processed using conventional production methods. What is special here, is that the fabrics sold under the Aersulate name are only 1 to 3 mm thick and achieve very high insulation values which are largely retained even under pressure and in moist conditions. Despite their high performance, they are still soft and can be used for shoes, clothing and work safety products, as well as for sleeping bags and technical applications. A patent for the process developed by Outlast has already been filed.

“Thanks to its extraordinary physical properties, NASA has already been using aerogel for many years,” remarked Volker Schuster, Head of Research and Development at Outlast Technologies. “For example, for the insulation of its Mars rovers and for capturing dust from the tail of a comet during the Stardust mission,” he continued. Since the development of aerogel by American scientist and chemical engineer Samuel Stephens Kistler in 1931, no-one had been able to apply the versatile material to textiles in large amounts without changing their original properties, despite intensive research. This means that the products were often not only very rigid, but made processing with conventional production methods impossible due to their high degree of dust abrasion. With its newly developed Aersulate technology first presented in June 2022, though, the specialist in textile thermoregulation located in Heidenheim, Germany is now writing insulation history.

High-performance insulation just 1 to 3 mm thick

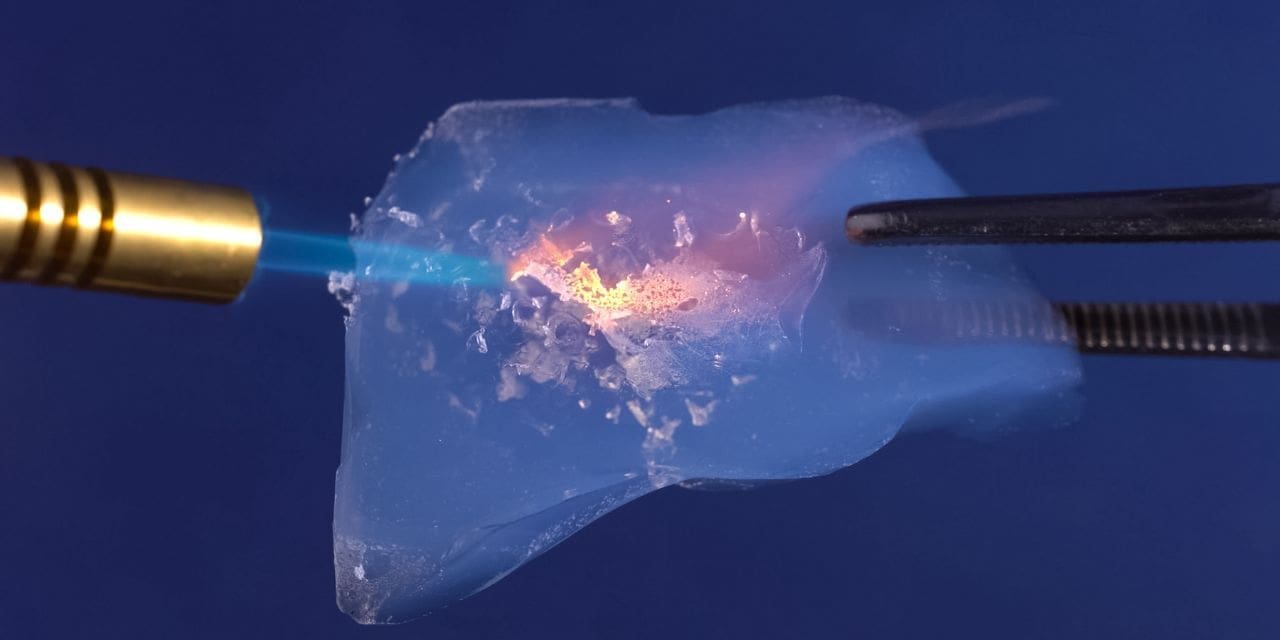

“The consistency of aerogel can be best described as liquid dust particles which spread uncontrollably throughout a room within seconds thanks to their minimal thickness,” explained Schuster. “This is why processing is a big challenge.” Despite these difficulties, Outlast Technologies has managed, after a development period of around five years, to bring an innovative process involving the adhering of aerogel between multiple layers of material to market maturity. Depending on the area of application, nonwoven fabric, felt and different composite materials can be used as the media. What is special here is that the properties of the respective textiles are not adversely affected by the Aersulate technology, meaning that they can easily be further processed with conventional means and under industrial conditions despite their acquired thermal properties.

As a silicate-based solid, aerogel is obtained from natural quartz sand, yet exhibits a density over 1,000 times lower than glass manufactured from the same raw material. The extraordinary thermo-insulating properties of the material are thanks to its extremely porous structure, which enables it to be composed of up to 99.8 percent air. “One liter of aerogel weighs just 50 g,” explained Schuster. “Just 10 g of the material has the same surface area as a soccer field, though.” Thanks to these properties, Aersulate textiles exceed all other previously known insulation materials in terms of performance, despite the fact that they are only 1 to 3 mm thick. Tests carried out by the German Institute for Textile and Fiber Research in Denkendorf (DITF) using the Alambeta method showed that the thermal resistance of an Aersulate fleece is more than double that of a conventional fleece of the same thickness. Add to this the fact that the thermo-insulating properties of Aersulate products remain high despite pressure and wetness, while they decrease enormously with other conventional materials like felt and polyurethane foam (PU) under these conditions.

Work safety and functional clothing with Aersulate

Thanks to the textile medium, thin Aersulate products are especially suitable for the shoe and clothing industry, as well as all areas of work safety. The user benefits from different properties, depending on the intended use. “With a glove made of Aersulate just 1 mm thick, you can put your hand into boiling water without being scalded, for example,” explained Schuster. “The material’s extremely hydrophobic properties play quite literally into our hands here.” In the case of knee patches on work and functional pants, as well as shoes and soles, on the other hand, the material properties also become relevant when compression occurs. This is because the thermo-insulation properties of other materials would be reduced little by little due to moisture from the outside and sweat from the inside on the one hand, and by the continual influence of body weight on the other.

In addition to the human body, luggage and technical devices can also be protected from extreme temperatures and the effects of weather with Aersulate. For this purpose, corresponding cell phone or equipment pockets could be sewn into garments, for example, to maintain their battery life even at very cold outside temperatures and to safeguard the devices from overheating in case of high heat exposure. “With the broad range of possible textile medium materials, Aersulate is suitable for all applications requiring high thermal resistance on the one hand, where only a little space is available and both compression and moisture can be expected on the other,” said Schuster in summary.