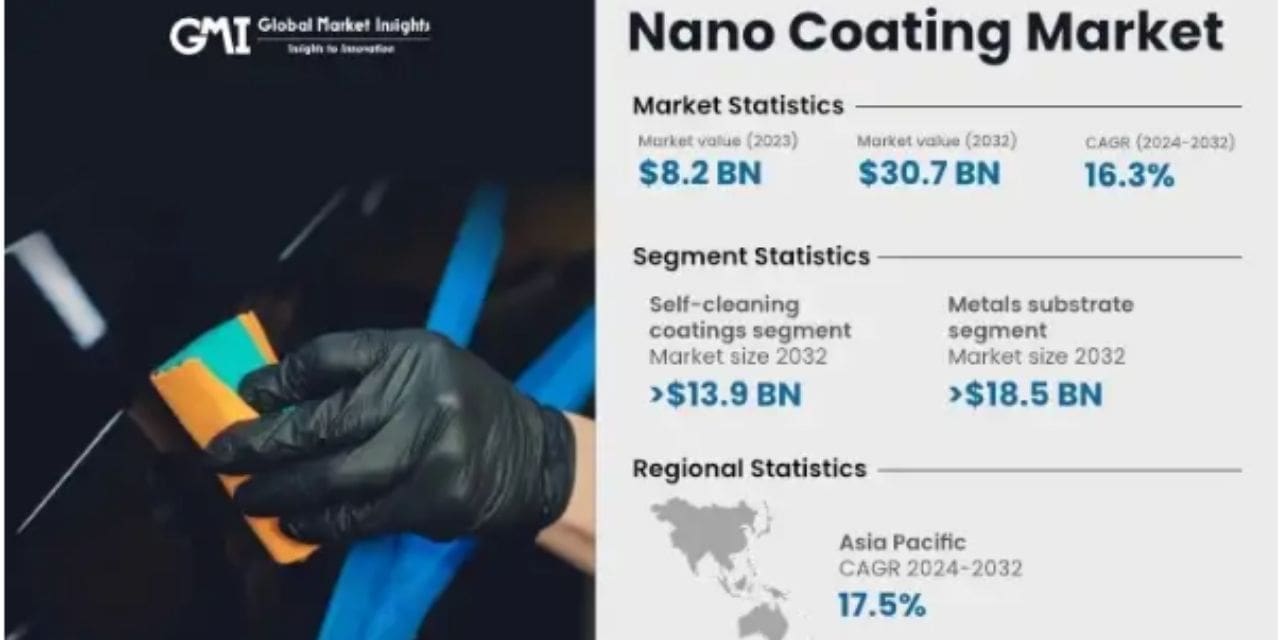

The nano coating market will witness 16.3% CAGR between 2024 and 2032, driven by the growing quantity of new product releases from industry leaders. Because of its special qualities, which include increased durability, resistance to water, and self-cleaning abilities, nano coatings are becoming more and more popular in a variety of sectors, including healthcare, electronics, and the automotive industry. To suit the changing needs of consumers and industries, leading companies are providing novel nano coating solutions with enhanced functionality, like enhanced scratch resistance and anti-corrosion properties.

For example, Hyundai Motor Company unveiled a new program in June 2024 that aims to improve vehicle cooling through the use of a Nano Coating Film. The goal of this program was to enhance their cars’ interior cooling.

Because these new product introductions offer improved performance and address certain industry concerns, they are propelling market growth. The incorporation of nanotechnology into coatings improves surface functionality, leading to more durable and effective goods. The need for nano coatings is growing as sectors look to use cutting-edge technologies for better performance and durability. This demand is being bolstered by continual innovation and developments from market leaders.

Depending on the kind, substrate, end-use, and geography, the entire nano coating industry is categorized.

From 2024 to 2032, the anti-corrosion coatings segment of the nano coating market is expected to grow at a remarkable compound annual growth rate (CAGR). These sophisticated coatings build a protective layer that increases tensile strength and prolongs the life of different materials, such as metals and alloys, by utilizing nanotechnology. Anti-corrosion nano coatings are being used more often in the automotive, aerospace, and construction industries to protect structures and parts against abrasive environmental conditions. These coatings’ exceptional corrosion-prevention capabilities, together with their affordability and lightweight design, are driving their increasing market share and appeal as a solution to major lifespan and maintenance issues in a variety of industries.

The glass market is expected to rise significantly between 2024 and 2032. Glass with nano coatings has amazing qualities like better water resistance, increased scratch resistance, and self-cleaning ability. These qualities are especially useful in industries where glass surfaces are vulnerable to damage and dirt buildup, like electronics, automobile, and architecture. Nano coatings enhance the upkeep and durability of glass by forming a protective layer at the molecular level, increasing its resistance to environmental pressures. The increasing use of nano coatings in glass applications is indicative of the need for creative solutions that improve aesthetics and functionality.

From 2024 to 2032, the European nano coating market is expected to grow at a significant rate. Nano coatings are becoming more and more popular in European sectors due to their improved performance qualities, which include increased durability, water resistance, and self-cleaning capabilities. In industries like automotive, aerospace, and construction, where improved coatings provide significant advantages like longer lifespans and lower maintenance requirements, demand is especially high. Furthermore, the use of environmentally friendly nano coatings is further accelerated by Europe’s stringent environmental legislation and drive towards green technologies. The market for nano coatings is growing as consumers and businesses in Europe look for innovative ways to increase the longevity and performance of their products.