Supply Chain Management

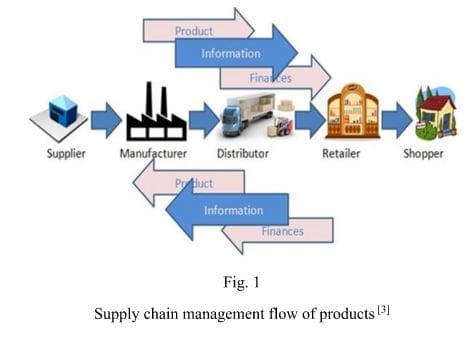

The management of the flow of goods and services that starts at the point of origin and concludes with consumption is known as supply chain management. Additionally, it includes the transportation and storage of raw materials used in ongoing projects, inventory, and fully furnished commodities. Monitoring and tying together the production, distribution, and shipment of goods is the core goal of supply chain management. Companies that have excellent and tight control over internal inventory, production, distribution, internal productions, and sales can do this.

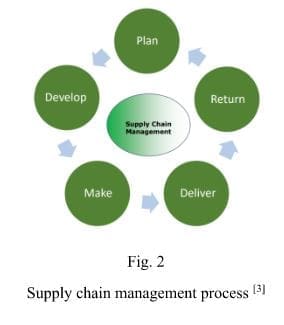

Companies utilise a method called supply chain management to make sure that their supply chain is functional and efficient. A company’s process for converting raw resources into finished goods is called a supply chain. The following is a discussion of the five fundamental elements of supply chain management:

Plan

Planning is the first step in the supply chain process. In order to address how the products and services will satisfy the needs and desires of the customers, we need to design a plan or strategy. Planning at this stage should concentrate primarily on creating a plan that generates the most profit. Companies need to develop a strategy for handling all the resources needed for creating products and offering services. The major goals of supply chain management include planning and creating a set of KPIs.

Develop (Source)

Planning is followed by either developing or sourcing. At this stage, our main focus is on developing a solid relationship with the providers of the production-related raw materials. This entails choosing various planning strategies for product shipping, delivery, and payment in addition to locating reliable suppliers. To get the goods and services they need to produce their product, businesses must choose suppliers. So, at this point, supply chain managers must develop a set of pricing, delivery, and payment procedures with suppliers as well as the metrics for managing and enhancing the connections. Eventually, supply chain managers can combine all of these procedures to manage their inventory of goods and services. Receiving and inspecting cargo, moving them to the manufacturing facilities, and approving supplier payments are all included in this handling.

Make

The creation of products that customers have requested is the third step in the supply chain management process. The products are conceived, created, tested, packaged, and coordinated for delivery during this phase. Thus, the supply chain manager’s job is to plan all the manufacturing, testing, packaging, and delivery-related tasks. The most metric-intensive step of the supply chain, where businesses may assess the level of quality, production output, and labour productivity.

Deliver

The delivery stage is the fourth stage. Here, the supplier delivers the goods to the client at the specified place. In essence, this step is the logistics phase, where customer orders are accepted and product deliveries are scheduled. The stage of delivery, which is frequently referred to as logistics, involves businesses working together to accept orders from clients, set up a network of warehouses, choose carriers to transport goods to clients, and set up an invoicing system to collect payments.

Return

The return is the name given to the very last and final stage in supply chain management. At this phase, customers return damaged or defective goods to the provider. Here, the businesses must handle client inquiries, address their complaints, etc. For many businesses, this segment of the supply chain is frequently troublesome. The supply chain planners must develop a responsive and adaptable network for receiving returned damaged, faulty, and additional products from their clients and streamlining the return process for clients who have problems with delivered goods.

A systematic exchange of resources, products, and related information between suppliers, businesses, retailers, and customers is what is meant by supply chain management. Types Three main flow types can be found in supply chain management:

∙ Material flow

∙ Information/Data flow

∙ Money flow

- Sustainability

Several stakeholders, including the media, consumers, non-governmental organisations, investors, governments, and academics, have given sustainability a considerable deal of attention. As a result, it is acknowledged as the dominant corporate framework on a global scale.

What is a sustainable supply chain?

A sustainable supply chain aims to reduce or eliminate harmful environmental and social impacts while transferring goods as swiftly and affordably as feasible to the downstream supply chain or end users. A supply chain that is sustainable is built on three pillars:

- Financial sustainability: A business with a sustainable supply chain should be able to provide a gratifying income to all of its stakeholders, including owners, investors, and employees, because longevity and sustainability are linked.

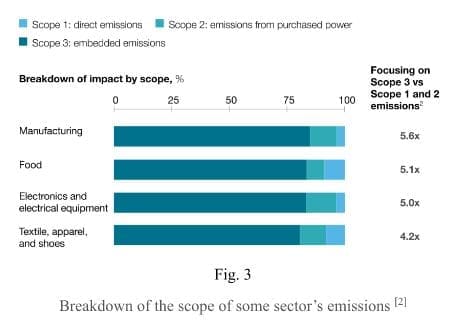

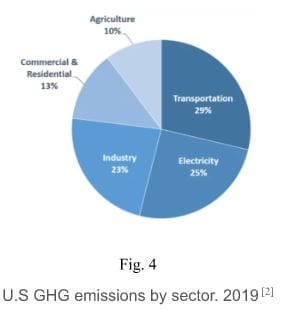

- Environmental sustainability: The least amount of GHG should be released in a sustainable supply chain. Consumer goods companies emit the majority of GHGs, or more than 80% of their total GHG emissions, under Scope 3 emissions (GHG emissions connected to supply chain, usage, and disposal) (see Figure 2). Total consumption is rising as a result of the growing global population and wealth. Hence, environmentally friendly supply chains are an effective instrument for lowering our carbon footprint.

- Social sustainability: Across the whole value chain, a sustainable supply chain respects human rights. A moral business associates with organisations that don’t employ child or forced labour. Notwithstanding the humanitarian aspect of the scenario, brand image distortions may result from a supply chain that is unconcerned with social sustainability. For instance, it was discovered last year that Starbucks’ coffee bean suppliers used kids under the age of 13 to save costs.

SUSTAINABLE SUPPLY CHAIN PRACTICES

In this section we will present top 7 best practices that will improve your corporate supply chain’s sustainability.

- Find the current pain points of your supply chain

- Optimize transportation

- Collaborate With Sustainable Suppliers

- Minimize inventory

- Reuse waste or by-products

- Use environmentally friendly packaging materials. [2]

Performance Impact of SSCM

Whether SSCM practises create a business case or not, business practitioners must provide some reason for the creation and integration of SSCM methodology within their organisations. Implementing SSCM techniques has the potential to provide a wide range of benefits to the practising business as well as supply chain partners, according to prior research on SSCM integration. For businesses that implement SSCM principles into their policies, plans, and operations, the SSCM method offers a variety of advantages. Improved investor appeal, employee value, risk management and mitigation, market appeal brought on by product stewardship strategy, investor appeal, and efficiency are a few advantages. In a related vein, Customer satisfaction, quality, suppliers’ innovation, trust, supply risk management, and fill rate are all influenced by SSCM processes. Other significant advantages of adopting SSCM include: better brand recognition for the company; increased ability to recruit and retain employees; decreased operating costs; transportation savings; better quality products; decreased risk of brand damage; savings from consolidation of shipments; and better working conditions, which may increase productivity. [1]

Advantages of sustainable supply chain management

- Minimising and avoiding risk

- Designing efficient business processes and strengthening the capacity for innovation

- Strengthening transparency and living up to higher standards in the business environment

- Sustainable supply chain management must be integrated into various existing internal processes to be effective.

- Sustainable supply chain management goes beyond direct suppliers.

- There are stringent requirements for data management. [1]

Conclusion

Future research endeavours should focus on exploring and empirically testing the monetary benefits of SSCM implementation as previous research inquiries have insufficiently addressed this important aspect to date. This type of research would help managers to understand and confidently implement SSCM practices in their respective business domains Moreover, more attention is required to examine the role of collaboration and networking in building supply chain sustainability including intra- and inter- organizational collaboration. It emphasizes to tackle sustainable supply chain issues, the company must collaborate with the network of firms it is embedded in, with governments or regulatory bodies, and making the most of every competence and resource available. Accordingly, enhanced outcomes may only be realized when all supply chain partners actively contribute, promote, and implement SSCM practices.

Reference:

- Sajjad, A., & Eweje, G. (2013). Sustainable Supply Chain Management-A Conceptual Framework, 60(4), 53–74. https://www.researchgate.net/publication/289968983 Retrieved January 15, 2023.

- 7 ways to improve your supply chain sustainability in 2023. AIMultiple. (n.d.). https://research.aimultiple.com/supply-chain-sustainability/ Retrieved January 31, 2023.

- TutorialsPoint. (2023, January 23). Supply Chain Management tutorial. TutorialsPoint. https://www.tutorialspoint.com/supply_chain_management/index.htm Retrieved January 31, 2023.