1] Introduction to Stretchable Fibers

Stretchable fibres, sometimes referred to by their brand names like lycra, spandex, and dorlastan, are another milestone in the evolution of synthetic fibres. Stretchable fibres like elastane, which were developed in 1937 in Germany, have characteristics not found in nature, with their amazing elasticity being the most significant. A general name used to describe elastomeric fibres with an extension-at-break of more than 200% and quick recovery after tension release is “spandex.” With a high reversible extension of up to 400–800%, these fibres behave in a way that is similar to rubber. Elastane, the name of the substance known as spandex, is an anagram of the word expands.[1]

2] Modified elastic yarns and fabrics

New dimensions explored in the manufacture of elastic yarns and fabrics in order to enhance the product value and productivity are discussed hereunder.[1]

2.1 Modification in Ring Frame:-

Using a ring spinning frame and a self-designed, multi-section drawing frame, it creates a polyester core-spun yarn with spandex fibres. Under varied processing circumstances, the mechanical characteristics of the core-spun elastic yarns were investigated. They improved the draw ratio to increase the elastic yarns’ breaking strength and elongation.[1]

2.2 Modified Rotor Spinner:-

The researcher created a self-designed multi-sectional draw frame and rotor twister to create highly elastic complicated yarns. By maximising the machine speed and twist to increase the yarn’s breaking strength, they looked at the mechanical characteristics of the elastic complex yarns.[1]

2.3 Air Vortex Spinner with Special Device:-

Using an air vortex spinner with particular attachments for bare spandex feed, the researcher created core-spun yarns with spandex in them. The qualities of the yarn were compared to those of typical vortex-spun yarn. He came to the conclusion that spandex and yarn count had a substantial impact on the yarn characteristics of elastic core-spun vortex yarns. Compared to regular vortex-spun yarn, spandex-containing core-spun vortex yarn displayed poorer tenacity and increased breaking elongation.[1]

2.4 Woolen Spinning with Special Device:-

Researchers investigated the effects of spandex drafting ratio and yarn twist factor on the tensile characteristics and elasticity of the core-spun yarn and concluded that spandex can be employed on modified worsted spinning systems to generate spandex core-spun yarn. The spandex drawing ratio and yarn twist both affect the characteristics of the yarn. As the yarn twist and spandex draw ratio are increased, the elastic recovery of core-spun yarns also increases.[1]

3] Dimensional and Physical Characteristics of Elastic Fabrics

- The loop length and amount of spandex are used to determine the dimensional properties of the knits. It is apparent that as the amount of spandex increases, loop length values remain nearly the same and the course and wale spacings decrease. Spandex Containing fabrics tend to be tighter. The weight and thickness of the fabrics are higher, but spirality is lower.

- The yarns with elastomeric components increase tightness factors, giving better dimensional stability to single jersey fabrics.

- Spandex is a lightweight, soft smooth synthetic fiber which has a unique elasticity.

- The spandex fiber is of better quality, light, and more adaptable compared to rubber. The fibers are made of innumerable polymer strands, because of which it possesses unique elastic property. Moreover, this fiber can stretch up to 500% of its length. The fiber is resistant to wear and tear caused by sweat, detergents, body oils, lotions, etc. When spandex fabric is used in garments, it prevents bagging or sagging of the material.

- Garments made of spandex gives perfect fit and comfort. Further, in spite of repeated stretching, it will retain its original length and shape.

- Fabrics with spandexare abrasion resistant and have negligible damage from ‘needle cutting’ when sewn, whereas in other elastic materials the needle sometimes causes damage.[1]

4] Testing of Elastic Materials

- Testing for elastane yarn and fabric is not similar to that used for hard yarn and its fabric.

- Because, the slight variation in spandex yarn tension affects its properties.

- Linear density of elastomeric yarns is tested using linear density apparatus following the ASTM D2591 -01 method.

- In measuring stress –strain behavior of elastomeric fibres, special clamps for bench marks are to be used to avoid false readings from necking out of threads as a result of the large reduction in yarn size which occurs at high extensions.

- Similarly, Elastic stretch and recovery of core-spun fabric is tested using ASTM D 4964 -96 method.

- Fabric slippage will be more for elastic fabrics which will affect the end results. It can be controlled by using band clamps at both the edges.[1]

5] Introduction to Spandex fiber

- Spandex is a lightweight, soft smooth synthetic fiber which has a unique elasticity.

- Due to its elastic property, it is used in making stretchable clothing. It is also known as ‘elastane’ in Europe and many other parts of the world.

- Spandex is made of synthetic polymer called polyurethane which has extraordinary stretch ability.

- The long chain of polymer is produced by reacting polyester with diisocyanate which contains at least 85% polyurethane.

- Spandex is strong,durable and was first invented at DuPont’s laboratory in 1959, in Virginia.

- Many areas of the garment industry were transformed after its arrival.[2]

6] Production of Spandex fabric

Plate No.1- Production process of Spandex fabric

7] Uses of Spandex Fiber

- It is well known that spandex is highly used in the apparel industry.

- However, this is also a useful fabric for hospitality and industrial organizations.

- Spandex fabrics are mostly used in garments where comfort and fit both are required like hosiery, swimsuits, exercise wear, socks, surgical hose, undergarments, gloves, cycling shorts, wrestling suits, rowing suits, specialized clothing like zentai suits, motion capture suits, denims, etc.[2]

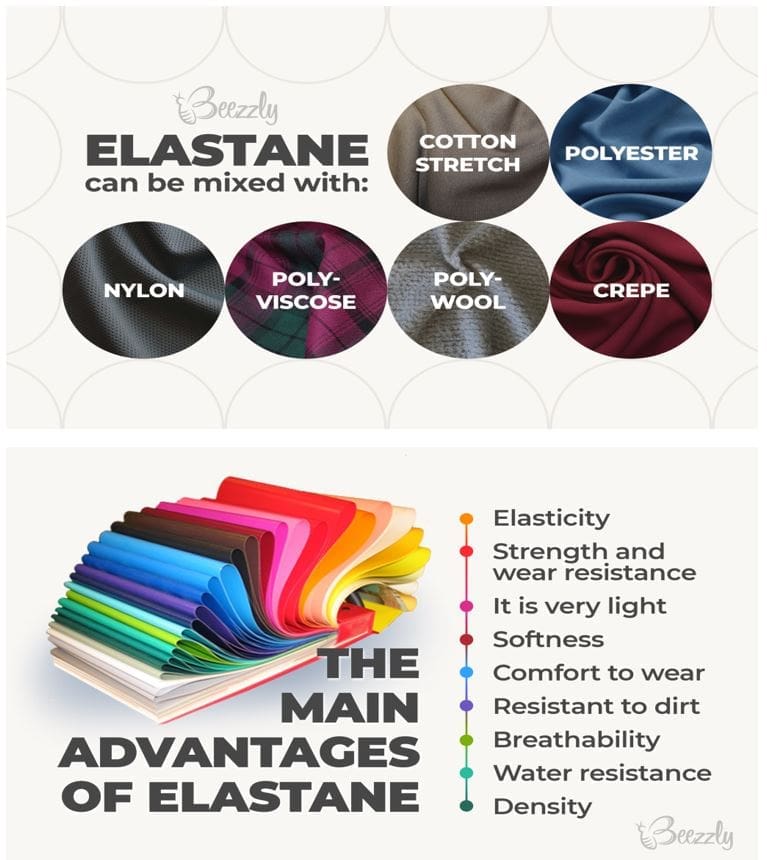

8] What fabric is elastane?

- Elastane (can be called “spandex” and “lycra”) is a synthetic polyurethane fabric that is similar in its main characteristics to rubber.

- Suppose we are talking about elastane and its properties, in that case, we have to mention that today it is rarely used in its pure form – exclusively in combination with other varieties of synthetic and natural fibers (with cotton, polyester, and much more).

- It is usually included as a part of viscose, cotton, silk, or knitwear garment, which improves their characteristics.

- It was produced in the 50’s of the last century in the United States. After that, polyurethane threads began to be actively produced in European and Asian countries.[3]

Plate No.2- Elastane fabric

Production of Elastane Fabric:-

Plate No.3- Production process of Elastane fabric

References:-

- Senthilkumar, M. (2011, September). Elastane fabrics – a tool for stretch applications in sports. Elastane fabrics—A tool for stretch applications in sports. Retrieved January 30, 2023, from https://www.researchgate.net/profile/Mani-Senthilkumar-2/publication/269338309_Elastane_fabrics-A_tool_for_stretch_applications_in_sports/links/5487eb2a0cf2ef34478ed22e/Elastane-fabrics-A-tool-for-stretch-applications-in-sports.pdf

- 2Fashion, F. (2013, December). Significance of spandex fibres: Elastane Fabrics. Fibre2Fashion. Retrieved January 30, 2023, from https://www.fibre2fashion.com/industry-article/7192/spandex-the-gen-next-fibre

- Moln, C., Stuart, Ava, Sofia, Olivia, Rosie, Isabelle, Poppy, Charlie, Jessica, James, Mia, Chloe, Ruby, Joseph, & Sophie. (2021, March 13). What is elastane? detailed guide from the experts. Beezzly. Retrieved January 31, 2023, from https://beezzly.com/what-is-elastan