Indo Count, which says on its website that it gives ‘Complete Comfort & Sustainable Momentum’, is a specialised end-to-end bedding manufacturer known in India and all over the world for its quality products. It has captured the markets in 49 countries. Known worldwide for its special services and quality, Indo Count has built its fame in the fields of retail, hospitality and fashion brands. In India, Indo Count has its corporate and marketing offices in Mumbai.

Kailash Lalpuria, Executive Director & CEO, Indo Count Industries Ltd, spoke to Textile Value Chain, in an exclusive interview.

Excerpts:

The home Textile industry is more unorganised (95%) SME Exporter/Producer from Karur, Erode, etc; how do corporates compete with these SMEs?

The first factor within this is the production capacity of the small business exporter.This business is not static, and it won’t be consistent throughout. There will always be ups and downs. For example, we get an order of 50,000 bedsheets one day and it sold around and so we get an order for 1 lakh bedsheets. However, a small merchandiser cannot fulfill this order as he has no capacity or bandwidth for production on such a large scale.

The bigger customers like brands from the UK and the US, like Walmart and Nike, do not go to small manufacturers because if the manufacturers have a capacity of 1 lakh meter processing and their minimum order is for 1 lakh meter processing, then their whole machinery will be used to 100% capacity, which is a risk because if the customer cancels the order, the unit will shut down and go into loss. So, they try to use a maximum of 25% sourcing from small manufacturers as it is feasible for both, the brand as well as manufacturer.

The second factor is the Financing capability of the business. If it shows that we can source material for 12 months of processing, they inspect if we have at least three months of material so as to ensure a supply chain for at least three months. Product innovation requires research, sampling and new types of yarns, chemicals and dyes. We need to send the team of R&D to the right sources to explore and because of how big of an investment it is, it is not always possible to conduct. We need to give a ‘Licensed Royalty’ in the case of big brands like Calvin Klein and Tommy Hilfiger. Small manufacturers are unable to obtain these licenses because they don’t have the financial capability to promote these brands. Hence, there is a promotional requirement gap between small and big manufacturers.

You can get a plethora of product options at our company, i.e. Indo Count, as we have the integration of spinning, weaving, dyeing, finishing, cutting and sewing. Hence, we have a better capacity. We also control all the points. There are places where only one operation is carried out like only weaving or stitching and then these are exported, giving a limitation to the type of products.Hence, such companies cannot compete with a company like ours where all processes are integrated. For example, in Ahmedabad, there are some exporters but they are not vendors for big brands like Costco, Target and Walmart as they are not able to fulfill such large capacities.

- SMEs participate in international exhibitions and can be seen there, so they must be having enough reach to have a stake the

Absolutely, the SMEs conduct a lot of export trades to smaller countries, where the norms are not so stringent for the supply chain. And they (smaller industries) are essential in order to service the smaller countries and their export. This will result in the growth of both, the company and the country. Because of this, the smaller merchandiser becomes stronger. Larger merchandisers will prefer orders from larger companies. For example, if there is an order of 10 containers from a giant like Walmart and there is an order of half a container from a smaller company, it is important that the manager first process the 10-container order. There are a lot of factors that go into making these decisions. There will be more focus on the larger order because of the visibility and potential it carries with itself for the growth of the company.With SMEs taking control of the smaller orders, we are able to efficiently fulfill the larger orders. This ends up being a profitable decision for all.

But we have a new unit of GMCL, which is more focused on carrying out the smaller orders from fragmented businesses and thus, we have a competitive edge. Here, we have a capacity of 45 million and cater to larger customers like E-commerce businesses or Licence Brand businesses. It is not huge, but small pockets of a large business bring help us build trust and credibility.

- When you have to sell to larger international brands like Walmart do you sell by their brand name or by make-to-order concept?

When it comes to B2B orders, we usually supply within the house brand that they have. So it is a make-to-order concept. But, in the last 3-4 years, we have become a major supplier in B2C and D2C,licensed brands and own developed brands. Given our incredible innovation integration, they are compelled to use our brand name in their product. Our products also connect better with customers and hence, they are more accepting of our brand name. For example, we have launched a brand called ‘Purer’, which has been very successful. It is an organic product where all dyes are organic and extracted from the waste products. Archroma, a chemical auxiliary company, has given us exclusive rights for this. Earlier, we used to use natural dyes in organic cotton and then the use of vegetable dyes become prominent. But it was objected to on the grounds that vegetables are meant for human consumption and shouldn’t be used for dyeing purposes. Then, we switched to the waste that is generated from edibles like almond coveralls/shells, palmetto leaves, waste from beetroot, and coffee waste. These can be used to extract dyes. These extracted dyes are completed natural as they do not use petroleum-based products/ pigments in them. When we use this in cotton, it becomes completely organic and hence, the name, ‘Purer’. This was very successful and we have an export business of around Rs. 250 crores. This product goes by the name of Purer but also has the name ‘Indo Count’ on its label.

We are slowly getting success in this way. Around 10% of our profits come from our brand name. We have many patents of our own, our product ‘Infinity’ is also a patent. Through our patents, our brand name is getting promoted. We have noticed that the bigger brands are comfortable with selling under our brand names because of the quality of our innovation and that is a huge achievement for us.

- What are your plans for the domestic market?

India has a very large market for home textile, which is around Rs 20,000 crores, out of which, Rs 15,000 crore is the unorganised market. The remaining Rs 5,000 crore market is organised. In India, there are cultural and regional influences on the textiles which are still very prevalent. These products are value-driven and hence, people buy these products, but this is an unorganised market. For example, if onegoes to Jaipur, Thiruvananthapuram or Assam, they will find different types of bed sheets (chaddar) there. These products differ region-wise. Another example is the Solapuri Chaddar which is very famous. However, with the use of GPay, Credit cards, etc becoming more common, these markets are slowly becoming organised. For example, 20-25 years ago, we used to go to Kalbadevi market to buy bedsheets. But now, we go to malls to buy these products. This shows the transition towards an organised market and has contributed about 9% of the market share. Our revenue is about 8% currently and we want to scale it up till next year. But we are facing certain obstacles because of the market share of a single product causing limitations and significant competition within the sector. However, our team is stronger now and our brands like ‘Boutique Cleaning’ and ‘Layers’ are being promoted very strongly in the domestic market, strengthening our position.

- Are you in talks with any brands or retailers for sales?

We are currently selling in Shoppers Sto and Home Centre. We are in talks with Reliance Home Centre and other retailers as well. Our main objective with setting to retailers is that we do not want to enter the retail market at the moment owing to its bandwidth requirements. Although we are able to expand, it is not where we are strategically headed currently. We have a strong presence in Tier 2 and Tier 3 cities owing to our 1,200 points of distribution in 20 states.

We also have a plan when it comes to branding. Once we have a strong foothold in the country, reach around 2,500 points of sales, generate enough recognition for our brand and receive good visibility, we will move into branding. For example, if I were to strike up a conversation with someone regarding Boutique Cleaning, they might not know about it very well.We want to expand pan India first. We would like our presence to be in all tier 2, tier 3, and tier 4 cities and the hinterlands of India.We want our distribution base to be strong along with our product reach. I think that opening a shop/franchise is easy but selling your product is the real task. A brand’s biggest win is when the product is available within a reasonable time for the customer. For example, Amazon became very successful because it was available to its customers and delivered in 24 hrs. A brand’s recognition and swiftness of supplying the product is what decides its positioning in the market. Our brands are new and are slowly being accepted in the market but we want to reach that space of easy access within the market.

One of our Unique Selling Points (USP) is the lack of standardization in our country. Mattresses are made in India based on the choice of the customers. We only provide king-size bedsheets. Now, normally the problem with bedsheets is that they don’t fit properly across the bed because of their size. But our king-sized bedsheets solve this problem regardless of the size and dimensions of the mattress.

- Which fibres do you use mainly, is it 100% cotton?

Our products are mostly cotton. In some cases, there are blends like Tencel made from viscose rayon.It is made from wood pulp and not petroleum-based products. In other cases, we use a blend of linen or hemp.

- Are you focusing on home textiles only? Or are you planning to venture into other domains as well?

Currently, we are focussing on home textiles. We are getting a very large revenue from bedsheets solely. Bed linen, overall, comes in soft furnishing. Within home textiles, 50% value is of bed linens and the other 50% is of towels, rugs, carpets, curtains, and upholstery. Bed linen is a very large market and hence we are currently focusing on growing this sector.

- What is your USP for bed linen in Indo Count?

First of all, we are a focused company. We specialise in making one good quality product as opposed to generalizing our products. Secondly, we are a debt-free company. Thirdly, we have an asset life model. We focus on branding, distribution and product development on the front end. We don’t do value addition at the end like in yarn making. It is done for the final product. Lastly, our product development is very strong. We have a strong team and great facilities and we are customer-centric. We bring about many innovations and provide solutions to the customers. We connect and communicate rigorously with our customers, making it a joint partnership. We understand the problems and the needs of the customers and retailers and provide necessary solutions on a timely basis. We recognize the customers’needs, develop the product accordingly, and then give it to the retailer for selling, promoting it through the retailers. This is our capacity and USP.

- Product innovation is your focus, and how much part of your revenue goes into this R&D? Is there any special team to do this?

We invest around 2% of our revenue in R&D and have a special team in India and the US dedicated to this. We see the potential and passion while hiring people for marketing. We evaluate their passion for textiles or to gain knowledge of textiles and work in this sector. I think that how one promotes their products forms the foundation of a lot of factors in a business. Our marketing people go and sell our products but they are also curious to know what other products are there. They conduct thorough market research and analyze the demands of the customers and provide personalized market solutions accordingly.

- Do you have plans for expansion in production?

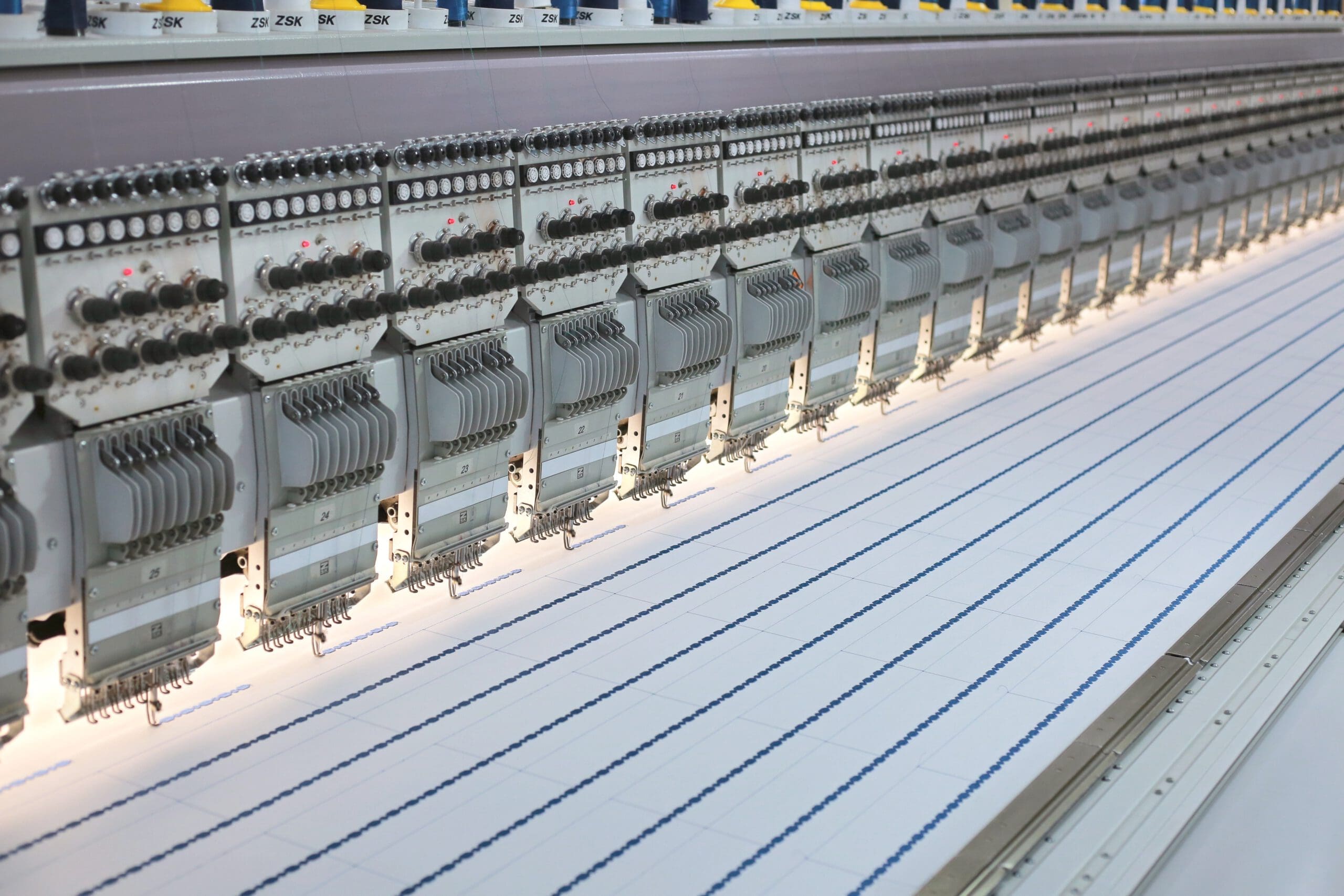

Our production facility started with a capacity of 36 million meters in 2007. Today, after 15 years we have reached a capacity of 108 million meters. With a recent acquisition, we were able to add 45 million tonnes to our capacity, making it a total of 153 million meters. There are periods of inflation, recession, and stagflation. There are so many variables that are to be handled and considering all this, our compounded Growth (CAGR) is 14% and 20% ROCE avg, which is a good growth rate.

- How much is your company’s dividend? And how is your stock price?

Despite the unfavorable conditions caused by Covid, our dividend was 100% this year. The prices of cotton have increased, and there is a decrease in demand. Inflation has also spiked owing to Covid. Considering all this, we have given a 100% dividend. We have earned and distributed our money to the stakeholders as well. We have also acquired GHCL this year, which is too soon to be called an investment currently.

We don’t always focus on stock prices. We put in our hard work. Our whole team works assiduously and eventually, we believe that we will get to see the results.

- There is a trend of fitted sheets now and IKEA uses these. Your opinions on fitted sheets, please.

The trend of fitted sheets will definitely grow in India. But the challenge in India is that there is no standardization of mattresses and sheets.Customers in Indiausually get a customized mattress according to their needs and choices. Some may opt for a 6-inch or 8-inch mattress,some might get a soft mattress, and some may get a spring one or a memory foam one.There are many variations in mattresses and people in India like to customize their mattresses based on their preferences. In many foreign countries, the bedside and the mattress sizes are usually fixed. Hence, we have developed ‘Truegrip, a patent for fitted sheets which fits a mattress from 8-inch to 20-inch owing to the elastics on its sides.

- What is your growth rate?

The fitted sheets are growing slowly and will get acceptance in the market eventually. One of the things that will help is if the mattress company will sell it directly along with their mattress. This will solve the issue of the fitting. But the sales of this product will rise in the future.

- How much is your turnover and export percentage? Do you target major retailers?

Our export is currently at 95% and our last turnover was Rs. 2970 crores. We export to more than 50 countries.

- Generally, people use synthetic blends for home textiles. But you said that you use cotton mainly and your tagline is based on comfort. When it comes to comfort, we immediately think about natural products. What is your take on this?

The comfort doesn’t depend on the fibres alone. If one has sofas or curtains made of cotton, it isn’t likely that one seeks comfort in that. We want comfort where we sleep. And we want good adsorbent fibres in our towels. Synthetics are not manufactured cheaply these days. The process of recycling these petroleum products is tedious and expensive. Moreover, these products are against the environment and thus, go against our values. Hence we do not use these products.

The market needs have shifted in the past few decades. Earlier, synthetics were prevalent to a large extent. But nowadays, everyone prefers natural or cotton-based clothing. One of the factors contributing to this shift in consumerism is climate change and increasing temperatures. Clothes are intimates and come in direct contact with the skin. Polyester is not breathable and causes rashes. But on the other hand, cotton gives comfort.It allows easy absorption of perspiration and dries up quickly after washing. All these factors have led to the acceptance of cotton and comfort definitely has played a large role in it.

However, in the case of curtains and upholstery, synthetics are preferred owing to their durable nature.

- What about other natural fibres like hemp etc?

All these other natural fibres are sustainable. There is a trend in foreign countries as well as among the youngsters to buy organic foods like organic atta (dough), and barley. This trend is mainly because of awareness. These sustainable fibres can be reused, recycled and it dissolves easily and it is not harmful to the environment. Hence, it has a growing popularity.

- What’s your stand on sustainability & recycling, particularly in the home textiles segment?

We, at Indo Count, are committed to sustainability. We have already put out our first ESG report as a company and it is within our internal circulation. We are registered on UNGC. We follow ten of the World’s 17 SDGs. We are also involved in the Paris Agreement which aims to reduce the temperature by 2%. We have made an agenda of reducing freshwater intake, making zero discharge of chemicals, restricting the use of plastic by 50% and reducing the use of coal by 50%. We have generated reports for this and it is quantified by SBTI. They conduct an audit to authenticate the claims that we make and will be checking our progress.

Recycling is prevalent. We also use recycled products. Currently, we are planning on recycling polyester and making yarns and other products from it. We believe in circularity as well. If a customer returns a bedsheet after use to the retailer, we would use it for making some form of garment or cotton or a thread and then make a sheet again. This cycle goes on. Our strong belief in it is reflected in our brand for it, which is called‘E coup’ and has a vast product portfolio.

We, as a company, focus strongly on Reuse, Recycle, Regenerate. We have reduced our freshwater intake by 55% and we reuse 92% of the water from the effluent. We have an investment of around Rs. 8 million in our ETP plant. The discharge is based on centralized ETP. We also use the hard, solidified sludge as a fuel in our boilers so as to reduce pollution. We have four certifications for organic cotton. We are connected with over 6,000 BCI cotton farmers under the cotton initiative. We are connected to over 15,000 farmers under the various initiatives to increase the yield of cotton using methods like drip irrigation and the use of pesticides and insecticides.

We are also making a centre of excellence in Akola. In Ekarjuna, situated in the Vadodara district, there is no such centre for cotton. We aim to be the first centre of excellence. PPPA along with the State Government and PDKV (Punjab Rao Deshmukh Krishi Vidyalaya) has launched a centre with an auditorium and organic and BCI farming, wherein any farmer can go in and learn about cultivating cotton in a proper and efficient manner. It will be equipped with scientists and soil specialists. It is spread over 40 acres. We are inspired by the centre of excellence made for Orange.

- Piyush Goyal has made a cotton advisory.

Yes, it is made because of the growing prices of cotton. It scaled to Rs 1,10,000 from Rs 40,000. This has caused a setback for India in the global market. We had requested the export of cotton be stopped because of how expensive it is. Exporting cotton to countries like Bangladesh and Vietnam would only strengthen their economy while causing prices to hike for us.If this cotton stays in India, the rates will be comparatively lower and we will get cotton. But these actions were not taken due to various factors. We believe that strategically, we must do a value addition here and then export at a higher price. All their plans are long-term like improving the yield or the quality of seed but there are no short-term plans, which is part of the issue.

- In September, they are saying that we will get more crops.

While there might be an increase in the crops, there is an increase in consumption as well. If one brings 3,50,000 spindles, the consumption will increase as well owing to the availability. Thus, the mill consumption will also be increased. And out of this, if we keep exporting at the same rate, we will witness a decrease in availability while the demand would continue to rise or remain the same. This deficit will cause the prices to continue rising.

- What are the current cotton rate trends?

Cotton had reached Rs 80,000. While other cash crops are going at half the price, we were able to get a good rate for the cotton crops. Earlier in 2004-2006, cotton was under essential commodities. I think it should once again be termed as an essential commodity. We also think that the export of raw cotton should be closed. While we do not oppose the export of yarn, the export of cotton is proving to be not a profitable decision for the consumers in the country. We need all the cotton being produced within India to sustain our industries. Additionally, there is no export value policy.

- At one time, cotton harvesting was maximum in Vidarbha and Marathwada regions. But, now they are harvesting Soyabean

The maximum harvesting of cotton continues to come from the Maharashtra region. This accounts for 54% of the harvest.

However, the cotton crops were damaged last year and caused an immense loss. They are a fragile crop and their damage has a lot of repercussions.

- There is a lot of discussion going about growing coloured cotton?

We are working on growing coloured cotton. In our Centre of Excellence, there is one special farm for coloured cotton, one for organic cotton and one for BCI. We can show the farmer how to grow it. The coloured cotton is developed from the seeds.

In our study of the past 4-5 years, we have observed that the farmers do not have adequate knowledge about the seed that has to be grown. Because of this, they get easily influenced by the seed sellers and end up buying the seeds that the seed-seller is pushing them to buy. Educating the farmers on choosing the seeds correctly is important.

There are many organisations and associations now that are working for the cotton industry but we don’t know the quality of their work. There should be less number of associations to get the work done effectively and efficiently.