Exclusive Interview with Dr. Mohit Raina

Biography – Dr. Mohit Raina MBA

Dr. Mohit Raina carried out his studies at IIT Delhi in India and then went to Germany to pursue his PhD. Dr. Raina started working at the RWTH Aachen University from Nov 2006 in the department of spinning technologies. In 2007 Mr. Raina headed the Department of Spinning Technologies and started working as an EU Research Consultant for the ITA RWTH Aachen. From October 2010 Mr. Raina led the division of Production Technologies & Textile Machinery at the ITA and was responsible for the Project Management, Strategy, Human Resources and Finances. Dr. Raina also headed the EU Research Coordination at the institute and had personally been involved in a number of EU as well as German projects. In 2013 Dr. Raina also successfully completed his executive MBA from RWTH Aachen, Germany and St. Gallen, Switzerland. Having established the growth of the field of Textile Production Technologies, Dr. Raina was entrusted with the field of composites in 2014. He worked as a senior expert on advanced composite building materials. In October 2014 Dr. Raina moved back to India after a stay of about 10 years in Germany to launch his own company by the name Raina Industries Pvt. Ltd. Raina Industries Pvt. Ltd. manufactures pre-cast glass fibre reinforced concrete and textile reinforced concrete. Parallelly Dr. Raina works as a consultant for RWTH Aachen and is their Indian representative. Dr. Raina is on the research advisory board of the ITA, RWTH Aachen and advises on the scientific strategy at the institute. Dr. Raina also pursues work in educating students on International Business at the SP Jain Institute of Management Research, Mumbai, India as a visiting professor and also in the engineering domain at VJTI Mumbai. To maintain ties with Germany Dr. Raina engages as an evaluator of German Research and Innovation with FKT, Berlin, Germany. Being a technocrat Dr. Raina is also involved in various committees at NITI Aayog, Government of India and the Ministry of Textile, Government of India.

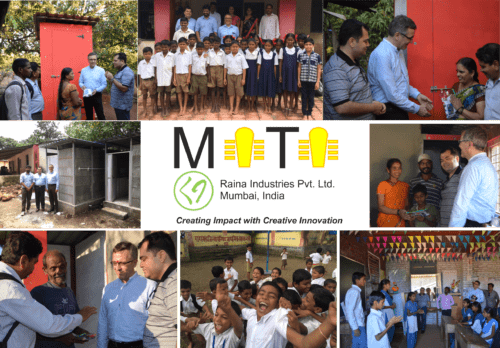

Raina Industries Pvt. Ltd. was started in 2014, under the ‘Make-In-India’ Initiative of the Prime Minister Narendra Modi. The Make-in-India team supported us to start the company, get registered as a start-up under the Department of Industry Promotion and Policy (DIPP). RainaIndustries is very specificallyan engineering and a manufacturing startup where we are looking at two aspects- 1. Focus on Value Addition – Howto bring in value addition into products and application fields ranging from medical, defense, transportation to infrastructure and 2. Focus on Sustainability – How do we bring in application of textiles in all these fields to boost textiles, increase jobs in this sector and at the same time to have the products in these fields which are more sustainable.

The company is headed by Dr.Mohit Raina who is texile engineer himself. According to him, he believes that textiles have got an abundant potential currently in the technical sectors and technologies can be indigenously developed to enhance export and at the same time reduce the import deficit the country is currently facing. Dr. Raina strongly believes that endeavors have to be undertaken to manufacture in India to facilitate more employment in the textile industry which is the second largest contributor to the country’s GDP..

Globally, themost innovative technologies are out of Europe and parts of the US. Thus, keeping in mind, the application of textiles in technical sectors, Raina Industries had decided to focus on end use applications. Raina industries has started with the construction sector or the infrastructure sector asa high growth potential was observed here, but the vision of Dr.Rainais to also extend the application to other industries like medical textiles, transportation, defense and more

Speaking on the infrastructure sector, Dr.Raina said, “Entire infrastructure sector is slowly adopting technical textiles. Amongall the materials existing in the world includingferrous and nonferrous materials, textiles contribute to 8 to 10% of materials. I believe India has a potential where one could substitute at least 15% of all currently used materials with textiles. Textile based materials are non-corrosive, sustainable and provide longevity to products made out of them.” He also feels that due to these properties these textile materials are are more sustainable and can be used in Construction, Medical, Geo textiles, Defense sectors and many more.

Challenges and hardships you faced during the journey

Speaking on the hardships, he said, “When wewere determined on selling a textile based product to sectors like infrastructure, roadways, waterways, industrial applications, transportation, the prospective buyers sitting on the other side of the table may or may not understand your product. Reason being, for everyonetextile is always an apparel. Also, the mindset is such that a textile industry and companies in the textile sector, always visualizes people working in shifts and blue collar jobs. However, they are unaware thatthe scenario is technical textiles is very different.”, he says.According to him, we need to have engineered solutions andsolutions which have been designed forspecific applications. For example the procurement department in the automotive sector will not ideally wish to buy a fabric in a rolled goods form. Thecar manufacturer who does notunderstand textile rolled goods, want their automotive components to be made. So if non-woven fabric manufacturers try to sell fabric for the roofs tops of a car, the OEM from the automotive industry like to have the entire car roof top, he won’t wish to have only fabrics for the roofs tops. So in orderto convince the automotive industry about these new textile based products,we have to invest lot of time into educating these people in the industries which are applying the textiles.i.e. automobile, infrastructure industries etc. We have to prepare a lot of prototypes, get tests results of the prototypes showing their validity in countries like India, finding out what exactly can be done for the market, execute pilot projects – these are the initial steps to be taken to break through the traditional mindset. We have to spend money upfront to prepare prototypes.Once the customer are convinced with the prototype models, they understand the product much better and allot a project. Raina Industries understandstextiles, they know how fabrics are made and how fibers are made and how these can be utilized. Raina Industries focus on integrating this knowledge into the final product so that the end user – a builder/ developer or a transportation company finds the same design, shape, size but with a much more sustainable solution.

The production capacity of RainaIndustries is currently distributed over three verticals- Façades,street furniture and modular tomorrow or modular toilets. Speaking on the growth and expansion, he said, “We are into business for thelast 3 Years and we are growing around 300% year-on-year. We started with a small project. In the early days we had clients telling us to do around 900 sqft. – 1000 sqft of Façade Cladding using textile based solutions. Today we have our smallest project which is around 16thousand sq.ft. of area.The growth from One Thousand to 16 Thousand happening in the last 3 years.” On the expansion plans, he said, “ Weare currently only in Mumbai. However, we have started getting inquiries from Delhi and Southern parts of India as well. I believe that the whole market viz. PAN India and PAN Asia, is a 500 crore industry. We are right at the start. ” On the product innovation part Dr Raina, who himself is a doctorate in the textile industry, feels that key preference has to be given to research and innovation. “We get innovative ideas and strategies from German counterparts. We depute one or two interns from Germany every year. They come with the mandate to develop something which may or may not exist in Germany. Students come with their final year of masters who are already equipped with the engineering perspective,are deputed to handle certain mundane tasks and find smart sustainable and engineered solutionson our construction site which are always challenging for us. Thus, weuse a lot of expertise to innovate. Inspired by the German Engineers, our engineers also start innovating and developing solutions for Indian challenges. “ The company aims at touching the 500 crore turnover in next 10 to 15 years.

The company also spendsquality time in innovations with the regular installations, which is a practicetheyindulge in everyday. Dr. Raina feels that in terms of research and development, internationalentities are ahead of their Indian counterparts. He also express that Indian corporate companies spend merely 2% on research.

Innovation in Conventional Textiles and ease of doing business in India

According to him, the cconventional textiles innovate on a day to day basis. What matters to the conventional textiles is the amount of impact the aforesaid innovation can bring. However, as far as in technical textiles, even a smaller innovation can bring bigger resultsand change the life of people.

Speaking on the ease of doing business in India, he said, “ Ease of doing business is based on one’s perspective, we work with lot with builders without much hassle in payment and documentation. Processes should be followed properly to get advantages and remove corruption.”

Technical Textile : India V/S International

Technical Textile : India V/S International

Technical textile market in India is always compared to the textile market in India, this is one of the biggest challenge. In technical textiles people tend to forget the technical world in the whole context.While referring to technical textile there has to be something technical about it i.e. the engineering aspect – which includes business engineering as well and not only the scientific engineering.Currently business model engineering for technical textiles is sometimes forgotten..

In India, people enter technical textile field without much knowledge. They starts with trading and followed by manufacturing after having entered the market. But it should be the other way round, in the technical textile segment one has to understandthe end user and get their technical requirements and then design the product.This practice is followed across the world but not everywhere in India.

The companies who are doing great in technical textiles in India are the ones who actually listen to their end users. A Filtration Company would listen to the filter applicator and ask him, what exactly he wishes to improve with the filter. Companies who are successful in technical textile follow the world practice; they listen intently to the application industry requirements and engineer their products accordingly.

Current issues being faced by user industry segment/ suggestions for improvement

Current issues being faced by user industry segment/ suggestions for improvement

Technical textile is an application based industry with high technicality. We need people from a technical background; e.g. in our company I am a textile engineer, but our staff comprises of mechanical engineers, production engineers, civil engineers etc. when I talk technical textiles with these guys they provide a very different perspective. In our company we make good and sustainable products. But the fate of our product, is decided not by the builder nor an architect but our local kadia( ground level worker – Mason). If the builder says yes and the kadia says no then it’s a mess, and then the sustainable material is automatically wasted. End users have to be bought to the forefront and their needs are to be addressed. The Building Sector hasa potential of contributing 20% of total market of technical textiles, but we are at around 0.1% now, huge potentials exist in this sector only if the executors and applicators are trained accordingly.

Similarly in medical textile, scope of Indian products is very huge. 15% or 20% of all materials used in this segment can be replaced with textiles.

Views on entering of new investor in this sector

New investors are slowly entering in the field of technical textiles. Fourth generation owners of conventional textiles companies are actually planning andfocusing on technical textiles. There is this new breed of textile entrepreneurs includingmyself, who want to change the textile scenario in this country, without affecting our conventional textile mills. We want to bring in value addition in the textile industry by means of Technical Textiles.

Branding Strategies in Indian and International Market

To preserve our brand quality, we make sure that our brand is having environmental compliance and gets certified asan eco-friendly product. In the future, the builders and developers will brand themselves as sustainable and eco-friendly.

Promotion and digital media in this sector

Promotion and digital media in this sector

Social media and the internet help in educating the industry. We are planning to promote our company in our user based industry media like construction media etc.