A.N.Sai Krishnan *, K. Sweda Keerthana, K Lokeshwari. and R. Sushidharan

Department of Apparel Technology, PSG Polytechnic College, Coimbatore

ABSTRACT

Green fashion is presently gaining movement towards sustainable and ethical practices in the fashion industry. It involves using eco-friendly materials and production processes, reducing waste and pollution, and promoting fair labour practices. Green fashion is about creating beautiful, high-quality clothing that is both stylish and responsible. By choosing to support green fashion, we can help reduce the negative impact of the fashion industry on the environment and support a more ethical and sustainable future. One aspect of green fashion which focuses on upcycling, examining the creative reuse of industrial cutting waste to create new fashion pieces. In this work, an attempt has been made to develop knitted apparel products from industrial waste fabrics and estimation of cost which also reveals the profitable impact on the manufacturing industries. A subjective evaluation is also carried out from the wearers’ perspective of the developed product.

-

INTRODUCTION

Green fashion, also known as sustainable fashion or eco-fashion, refers to clothing and accessories that are designed and produced in an environmentally friendly and socially responsible manner. It encompasses various practices such as using organic or recycled materials, reducing water and energy consumption during production, promoting fair labour practices, and minimizing waste and pollution throughout the supply chain. Green fashion aims to create a more sustainable and ethical alternative to the conventional fashion industry, which often has negative impacts on the environment and workers’ rights. By choosing green fashion, we can support brands that prioritize sustainability and contribute to a more eco-conscious and socially just fashion industry. It is an innovative approach to use upcycled garments from industrial wastes, it is a departure from the traditional linear economy, where resources are extracted, used, and then discarded. In a circular economy, the focus is on creating a closed-loop system where materials are continuously reused, recycled, or repurposed. This involves designing products with durability and recyclability in mind, promoting the reuse of products through repair and refurbishment, and ensuring that materials are recovered and reintroduced into the production cycle at the end of their life. By embracing circular economy principles, we can reduce the strain on natural resources, decrease waste generation, and mitigate environmental impacts. Ultimately, a circular economy offers a more sustainable and regenerative approach to consumption and production, paving the way for a greener and more prosperous future.

-

BASICS OF CIRCULAR ECONOMY

In the apparel industry, a circular economy represents a fundamental shift away from the wasteful and unsustainable practices of the traditional linear fashion model. It encompasses a holistic approach that promotes eco-friendly materials, responsible production, and consumer awareness. This paradigm encourages the design of durable and timeless clothing, repair and alteration services, and the development of resale and second-hand markets. Recycling and upcycling are central to this concept, where old textiles are repurposed into new garments or transformed into new fibres for production.

The goal is to extend the lifespan of clothing, minimize waste, and reduce the industry’s ecological footprint while fostering ethical labour practices and educating consumers about the environmental impact of their fashion choices. A circular economy in the apparel industry aligns with the principles of sustainability, resource efficiency, and responsible consumption, driving the fashion world towards a more environmentally conscious and responsible future.

-

ADVANTAGES OF CIRCULAR ECONOMY

- It reduces the need for virgin resources by promoting recycling and reusing materials.

- Minimizes textile waste and the burden on landfills.

- Reduces greenhouse gas emissions, water usage, and pollution associated with textile production.

- Creates jobs in areas like repair, recycling, and upcycling, and reduces production costs through sustainable practices.

- Connecting with environmentally-conscious consumers gains a competitive edge and enhances a brand’s reputation and social responsibility image.

- Encourages innovative design and business models. Makes supply chains more resilient by reducing dependence on raw material imports.

- Helps brands prepare for evolving environmental regulations.

-

METHODOLOGY

3.1 Upcycling by Industrial Waste

In the initial phase of our work planning, our primary objective was to identify the apparel industry from which we could source fabric waste for upcycling. After conducting a comprehensive assessment, it became evident that all fabric waste generated within the selected industry was primarily collected from the cutting department in a mass production apparel industry This department emerged as the primary hub for fabric waste, making it the focal point of our sourcing strategy. By concentrating our efforts on this specific source of waste material, we can efficiently streamline our upcycling process and maximize the utilization of available resources. This critical insight into the origin of the waste materials has allowed us to tailor our approach to target this department for the collection and transformation of fabric waste into sustainable upcycled products. We have collected cutting waste of knitted fabric from the cutting machines shown in Figure 1. After the collection of fabric waste from the cutting department, the next step in our process involved the careful weighing of the collected waste materials. This crucial measurement allowed us to quantify the volume of fabric waste obtained, providing us with valuable data for our upcycling work. Weight data serves as a fundamental metric for tracking and analyzing waste management and resource utilization, helping us make informed decisions regarding the design and production of upcycled products. This precise quantification of the collected waste forms the basis for the subsequent phases of our work ensuring efficient and sustainable utilization of these materials.

Figure 1. Collection of cutting waste of knitted fabric

3.2 SHAPE ASSESSMENT AND THEME CREATION

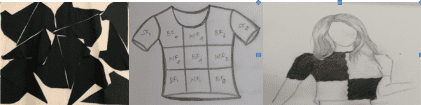

Following the weighing of the collected knitted fabric waste, we proceeded with a comprehensive shape assessment of the materials. This assessment involved a meticulous examination of the various shapes, sizes, and forms of the fabric waste. By categorizing the waste based on its shape characteristics, we gained valuable insights into how these materials can be best repurposed and upcycled. Understanding the different shapes within the waste stream allows us to make informed decisions regarding the design and manufacturing processes for upcycled products, ensuring optimal utilization of these resources. This shape assessment serves as a critical foundation for our work, enabling us to tailor our upcycling techniques to the specific characteristics of the fabric waste and how well we can utilize it to make an appealing garment. Firstly the cut waste was collected in an irregular polygon shape which was further developed into a 2d rectangular form for shape assessment. Figure 2 shows the shape assessment and theme creation of the cut waste. Once done with shape assessment we progressed in creating the theme of the garment. We choose to give the garment a chessboard theme with white and black/red fabric.

Creating a theme board for product development involves assembling a visual representation of the construction approach and design concept. This board combines technical sketches, construction methods, fabric samples, and descriptive text to convey the theme and style of the garment’s construction shown in Figure 3. The arrangement and layout of these elements on the board are essential for effectively conveying the intended construction methods and design goals. The theme board serves as a reference guide throughout the construction phase, ensuring alignment with the envisioned design concept. Garment construction is the process of transforming fabric and other materials into a finished apparel product.

Figure 2. Shape Assessment and Theme creation

3.4 EVALUATION OF UPCYCLED GARMENT

Evaluating the product resulting from upcycling involves a dual approach. Objectively, it necessitates a thorough examination of quality, cost-effectiveness, environmental impact, material efficiency, and market potential. This data-driven analysis allows for a clear assessment of the product’s overall performance, sustainability, and economic viability. Subjectively, the evaluation encompasses user feedback, aesthetics, comfort, brand alignment, and emotional resonance. These qualitative insights provide a deeper understanding of user experiences, design appeal, and the product’s ability to evoke positive emotions. The combination of both objective and subjective criteria offers a holistic perspective, facilitating well-informed decisions to refine the upcycled product and tailor it to user needs while achieving sustainability goals.

3.5 COSTING AND SUBJECTIVE EVALUATION

The costing of an upcycled garment involves a thorough analysis of expenses related to its production by calculating material and manufacturing costs prevailing in the apparel industry, and pricing strategies to ensure the upcycled garment’s viability in the market. Regarding the subjective evaluation, the questions for upcycled garments made from industrial wastes were asked of customers. The key questions were asked the wearer about the developed product such as 1. How likely are you to buy upcycled garments from garment waste? 2. Are you aware of the benefits of upcycling materials from garment manufacturing waste? 3. Would you pay extra for upcycled garments supporting sustainability? 4. How important is it to support sustainable fashion brands?

-

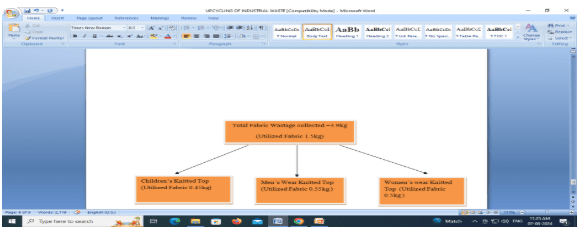

WEIGHT ALLOCATION FOR THE DEVELOPMENT OF UPCYCLED GARMENTS

The collected knitted fabric wastage from the cutting department and utilized fabric for each style development is shown in Figure 3.

Figure .3 Utilization of Fabric Wastage

- UPCYCLED GARMENT DEVELOPMENT

Based on the theme we have developed a patchwork garment from the industrial waste fabrics. Totally 1.5kg of fabric is used to develop the garment for children’s, men’s and women’s wear category of age 10 – 12 The garment (men’s wear) is developed by using the collected waste fabrics by using by red, white and grey scrap fabrics and the women’s wear has been developed using the white and red scrap fabrics and shown in Figure 4.

Figure 4. The final appearance of the developed product

-

SUBJECTIVE ANALYSIS FROM THE WEARER FOR UPCYCLED GARMENTS

Figure 5. Subjective Evaluation

Figure 5 shows the subjective opinion of children’s, men’s and women’s wear from industrial wastes. The buying behaviour for men’s wear is good and all the categories of the garments showed keen interest in the benefits of upcycled garments. It’s interesting that women are willing to pay extra money to buy upcycled garments and overall support of sustainable brands is very good . Table 1 shows the cost estimation of upcycled garments made from industrial wastes By utilizing the waste of 1.5 kg of fabric we were able to give a value addition of Rs.620 for three products and the retailer can also get a substantial profit by making a tag as a green fashion product developed by upcycling.

Table 1 Cost Estimation of Upcycled garments

| Description | Children’s | Men’s wear | Women’s wear |

| Fabric weight, kg | 0.45 | 0.55 | 0.50 |

| Fabric cost / kg, Rs | 270 | 270 | 270 |

| Total fabric cost, Rs | 121.50 | 148.5 | 135 |

| Manufacturing cost, Rs | 30 | 80 | 50 |

| Profit 10 %,Rs | 15.15 | 22.85 | 18 |

| Total cost, Rs | 166 | 251 | 203 |

CONCLUSION

We have successfully completed our work by incorporating the development of green fashion products through upcycling. In conclusion, this work stands as a testament to the exciting possibilities of upcycled and recycled materials within fashion. The subjective evaluation reveals a unique aesthetic—a blend of resourcefulness and ingenuity. The industrial waste garments developed have a good scope to generate profitable income, and mass production in our study has a more substantial response. The upcycled industrial waste takes on a new life and serves as a beacon, inspiring the fashion industry to embrace its creative potential for a more responsible and environmentally conscious future.

REFERENCES

- Dissanayake, D., Weerasinghe, D. ‘Towards Circular Economy in Fashion: Review of Strategies, Barriers and Enablers’. Circular Economy and sustainability. 2, 25–45 (2022).

- Xie, Xiufen, et al. ‘A Systematic Literature Review for the Recycling and Reuse of Wasted Clothing’. Sustainability 13(24), 2021.

- Reet Aus, Harri Moora, Markus Vihm, Reimo Unt, Marko Kiisa and Sneha Kapur Designing for circular fashion: integrating upcycling into conventional garment manufacturing processes’. Fashion & Textiles 8, 34 (2021). 3.

- Townsend, K., & Mills, F. Mastering zero: how the pursuit of less waste leads to more creative pattern cutting. International Journal of Fashion Design, Technology and Education, 6(2), 104–111. (2013).

- Nicola Saccani, Gianmarco Bressanelli and Filippo Visintin, ‘Circular supply chain orchestration to overcome Circular Economy challenges: An empirical investigation in the textile and fashion industries. Sustainable Production and Consumption,35 469–482,(2023).

- Carlos Rafael Silva de Oliveira, Afonso Henrique da Silva Júnior, Jéssica Mulinari & Ana Paula Serafini Immich, ‘ Textile Re-Engineering: Eco-responsible solutions for a more sustainable industry’, Sustainable Production and Consumption,28 1232–1248,(2021).

- Bocken, N. M. P., De Pauw, I., Bakker, C., & Van Der Grinten, B. ‘Product design and business model strategies for a circular economy’. Journal of Industrial and production engineering, 33(5) ,2017.

Acknowledgement

The authors acknowledge the support given by the Management, the Principal and the Head of the Department of Apparel Technology, PSG Polytechnic College for their encouragement and support in the completion of this work and SNQS Internationals Green Fields, Tirupur for supporting us in the development of apparel products.