Abstract

Currently, all denim is made out of cotton fibres or blends with high cotton content using a twill weave. However, denim has a poor environmental balance sheet, which starts with the planting of the cotton needed for it and continues with the high water consumption and use of chemicals.Therefore, in order to reduce the emissions caused by these, possible alternatives are being sought. A possible alternative, which is considered in this paper, is the use of hemp fibres to substitute cotton. Various aspects such as the cultivability, producibility and processability of hemp yarns are considered here. The results show that hemp can be grown and processed locally very well.Unfortunately,some further research and development is required for pure hemp fibres processing on a rotor spinning machine in a process-stable manner. Based on this, recommendations are given on how rotor spinning machines can be adapted constructively to overcome this deficit.

Introduction

The role of climate change and thus a sustainable world is becoming increasingly important. In 2012, the members of the United Nations set 17 goals to create a more socially and ecologically sustainable world. One of these goals is “Responsible Consumption and Production”. Relevant here are not only environmentally friendly end products, but transparent and sustainable processes throughout the entire product creation process. [UN15] Natural fibres are thus becoming increasingly important both in the clothing sector and for technical textiles. Up to now, cotton has made up by far the largest share of natural yarns produced. In jeans production in particular, it becomes clear how much need there is for improvement with regard to sustainability aspects. Not only the very high water consumption, the use of chemicals for cultivation and dyeing but also the long supply chains with their ecological impacts [Opp14].

Therefore, this paper focuses on the consideration of more sustainable alternatives in jeans production. For this purpose, the usability of hemp is looked at on different levels. First, the properties of the fibres themselves are discussed and later the technical feasibility of producing yarns. For this purpose, the production with the help of the rotor spinning process is examined more closely. Rotor spinning was chosen in a project for producing technical textiles because of its fabric resistance and yarn propertiesas well as the productivity compared to ring spinning. It turned out, that with minor developments and changes in the rotor spinning machine, a fine Ne 20 yarn was producible which is suitable for denim use as well. Rotor spinning without any additional changes however is currently not yet possible with 100% hemp but only with the addition of cotton. Mostly, between 50 to 70 %of cotton are added. Based on this, target values are defined that should enable the production of hemp yarns. Finally, statements are made about the extent to which production is possible with the help of changes to construction-specific aspects.

State of the art

Fibres

As mentioned, jeans production is mainly based on cotton. In terms of sustainability, however, cotton has disadvantages compared to other natural fibres. The plant is demanding, it needs warm temperatures without sudden temperature transitions. At the same time, cotton plants have a high water requirement of 1214 l per kg in average [BCE19]. Cultivation mainly takes place in tropical and subtropical areas [Hor20]. Hemp, on the other hand, can be grown locally everywhere, which is particularly attractive for the European market. This means that long, CO2-intensive routes, for example, can be avoided.Additionally, cotonised hemp fibres have fineness, softness and spinning properties that are close to those of cotton. Here, important factors in fibre preparation are retting and subsequent mechanical preparation.

As a domestic alternative, hemp is accordingly gaining increasing attention in Europe. The needs of

the hemp plant are predestined for the European region. Moreover, hemp is much less demanding to

grow than cotton. The plant is very robust against pests, which is why neither pesticides nor herbicides

are needed. Furthermore, hemp in general requires no artificial irrigation. With sufficiently good

processing, hemp fibres offer application possibilities in various textile sectors. High absorbency and good thermal conductivity make hemp interesting for the clothing sector and thus also for jeans production. This shall lead to a cooling effect while wearing. The high fineness-related strength namely offers opportunities for home textiles as well as technical textiles. Due to their weather resistance, the fibres can also be used in areas where synthetic fibres currently dominate. [CGP+08, KRM20]

Since jeans are not only made of cotton but also of synthetic fibres, this is another argument for the use of hemp in the production of textiles. In addition, hemp has other advantages, such as the fact that it is very prolific and covers all weeds, and that it absorbs a lot of CO2 as an C3 crop. Thus, the sustainability aspect is once again emphasised, as the plant does not only save CO2 due to logistical circumstances, but because of characteristics such as water consumption and CO2 absorption. [Nov01]

Production

The use of hemp fibres as an ecological and cheap alternative in the textile industry is currently facing two primary challenges. On the one hand, the processing methods used in the industry for hemp fibres involve ecologically questionable processes and are too expensive in the given quantities for successful marketing of the material, and on the other hand, the spinning processes used for hemp fibres are not competitive due to low product diversity and number of buyers.

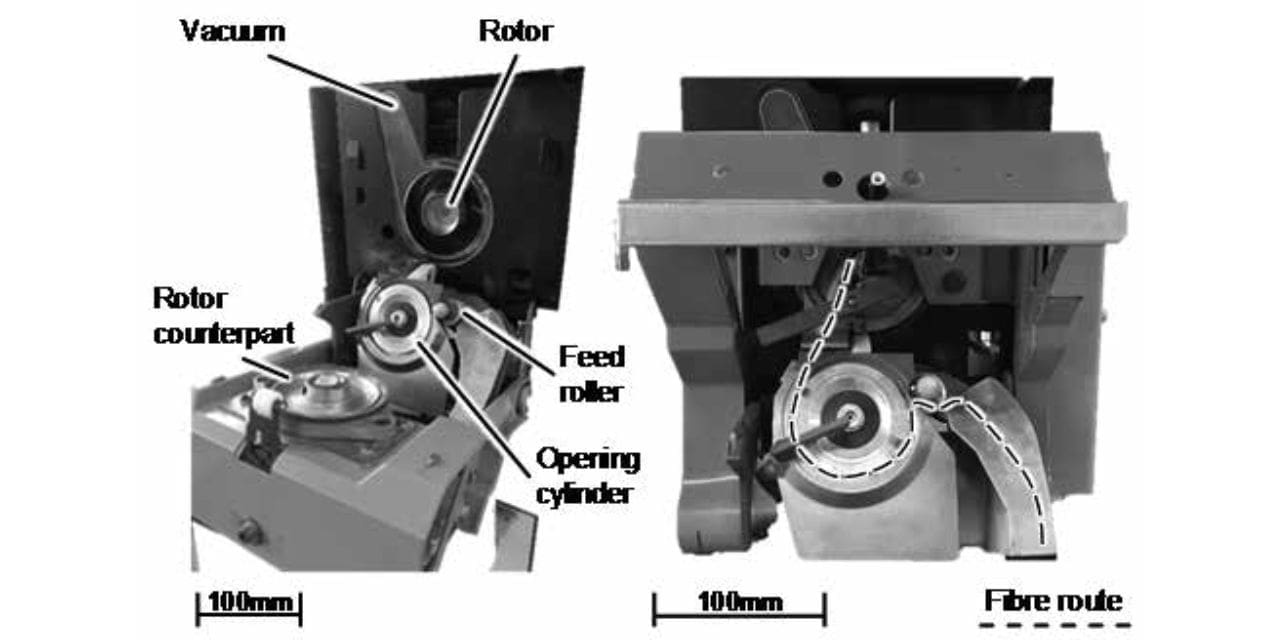

The rotor spinning (cf. Figure 1) process is adopted for the production of hemp yarns. However, the processing of hemp is made more difficult by the physical properties of the fibres, as on the one hand they have a high bending stiffness compared to cotton, which makes the initiation of the twist more difficult, and on the other hand dust is produced during processing, which is deposited in the rotor groove and strongly influences the spinning stability in the long run.

There are modern approaches for a competitive use of hemp fibres. In principle, various alternative processes can be used for fibre digestion. The fibres can be digested mechanically, physically, chemically physically or microbially. In the European industry, ultrasonic digestion and steam pressure digestion are currently used. The number of short fibre lines for the digestion of hemp fibres is low due to the lack of further processing options.

In a cross-border project of Germany and the Netherlands “Regional hemp chain for textile production”, a jeans fabric could be produced with hemp fibres broken down by steam pressure. The yarn was spun on slightly modified rotor spinning machines. However, 50 % cotton was added for better processability. The aim here, however, is to completely dispense with the addition of cotton and to enable production with hemp fibres only.

Implementation

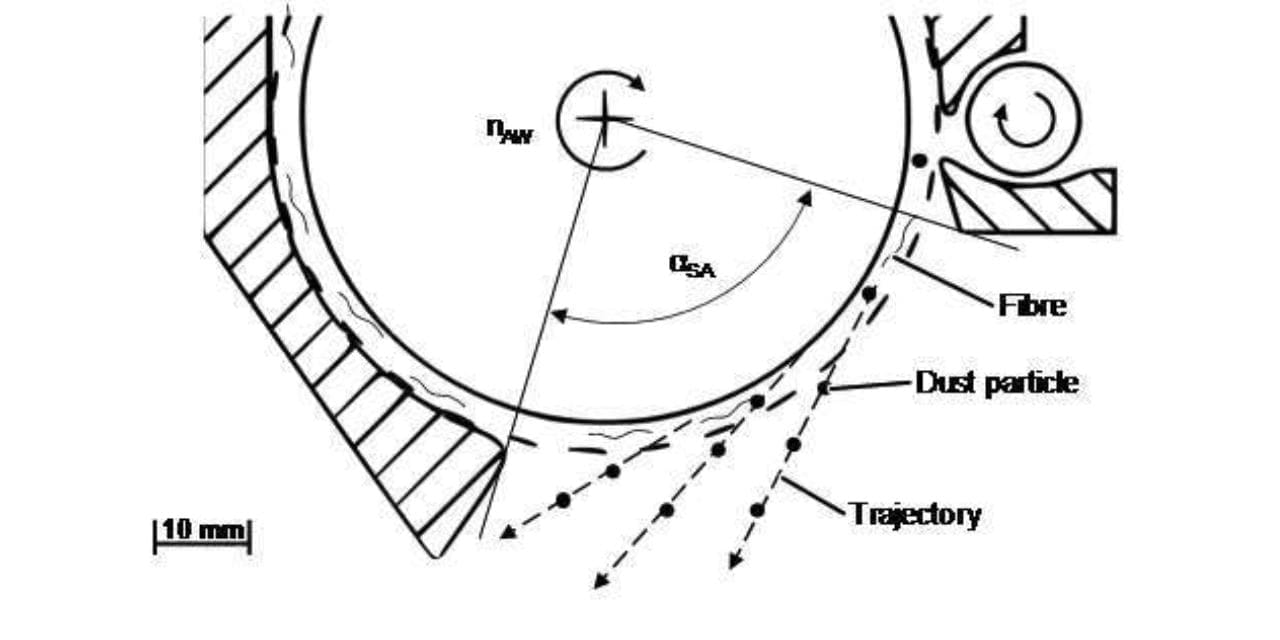

In order to enable production using the rotor spinning process, requirements have been identified which must be fulfilled. On the one hand, this is the removal of dirt (cf. Figure 2) while keeping as many fibres as possible in the opening roller of the system. Two possibilities have been identified for this:

1. The existing dirt separation can be improved 2. The system can be supplemented with an

alternative dirt separation mechanism

Figure 2: Sketch of dust removal in a rotor spinning box, based on [Tro95]

Another possibility is not to remove the dirt, but to directly combat the cause of the dirt and to contain the formation of it.

The following principle solutions were identified for these two possibilities:

a) Radial suction of the opening roller

b) Axial suction of the opening roller

c) Rotor equipped with dirt separation openings

d) Cross-flow in the combing-out area (direction of action 1)

e) Cross-flow in the combing-out area (direction of action 2)

For the technical and economic comparison, the following criteria are used for evaluation:

a) Acquisition costs

b) Operating costs

c) Conversion costs

d) Expenditure for change of material

e) Restrictions on the choice of spinning media

Results

When looking at the potential of hemp fibres themselves, it becomes clear that they are a very good alternative to cotton in terms of sustainability aspects. Hemp yarn production, on the other hand, has shown that there are still some problems to overcome.

Results show, that that for the considered principle solutions for rotor spinning, due to the additional costs for production changes and possibly more often lot changes, if the market does not rise significantly by higher offers.Also, the high conversion effort for automated systems, extraction is the worse alternative compared to the rotor concept for industry. If the rotor concept becomes established in industry, the acquisition costs will also decrease and the number of available rotor designs will increase. In this case, the rotor concept would also score better in terms of flexibility and would also be a good option for contract spinning mills.

During the production of hemp yarn on commercially available rotor spinning machines, however, high fibre damage and dust formation occur. This is due to the high brittleness of the hemp fibres compared to cotton in connection with the mechanical stress during the opening process, which is usual for the rotor spinning process. The resulting dirt deposits in the rotor groove impair spinning stability in the long run. Based on this, possibilities were worked out to reduce these dust deposits constructively. In doing so, the improvement of the current dirt separation as well as a potential addition to it were examined. It was also investigated whether the formation of dirt can be reduced by constructive measures. The aim here is a stable spinning process for pure hemp yarn.

Results show, that at the present time, it is not possible to evaluate the principles in a way that adequately reflects reality. Above all, the fulfilment of the function and the strength of the undesirable

influences on the spinning process cannot be determined with certainty. The respective influences have not yet been sufficiently investigated for the processing of hemp in order to find a systematic solution for the constructive containment of fibre damage.

Conclusion

The results show that hemp in general has a high potential to enable a more sustainable denim production. Hemp fibres have many advantages over cotton in terms of sustainability.The advantages of hemp over cotton are manifold. On the one hand, the fact that hemp can be grown locally everywhere speaks for its use. This would eliminate long transport routes and save a significant amount of CO2. In addition, hemp requires significantly less water for cultivation than cotton and significantly smaller amounts of pesticides are used. Last but not least, hemp absorbs significantly more CO2, which is another important aspect of sustainability.

In order to be able to use this advantages of hemp over cotton as much as possible in the future and to validate the assumptions made in this paper regarding the production of hemp yarns, more empirical trials with hemp fibres should be carried out. In doing so, the effects of the spinning settings on the fibre damage must be checked. This would realise large savings of CO2 in the production of denim in the future and thus enable a more sustainable textile production all over the globe.

Acknowledgement:

The research project ZF4558957CJ9 (SustainPol) of AiFProjekt GmbH, Berlin, is funded within the framework of the Central Innovation Programme for SMEs (ZIM) by the Federal Ministry for Economic Affairs and Climate Action (BMWK) based on a resolution of the German parliament.

References

[BCE19] Bremen Cotton Exchange

Cotton: No thirsty plant

Press release March 22nd 2019

[CGP+08] Carus, M.; Gahle, C.; Pendarovski, C.;

Vogt, D.; Ortmann, S.;

Grotenhermen, F.; Breuer, T.;

Schmidt, C.:

Gülzower Fachgespräche,

Volume 26

Hürth: nova-Institut GmbH, 2008

[Hor20] Hortmeyer, E.:

Top 10 Cotton Producing Countries

in the World, Discover Natural Fibres

Initiative, 2020

URL: https://dnfi.org/cotton/top-10-

cotton- producing-countries-in-theworld_

4785/, access on 17.05.2021

[KRM20] Kozłowski, R. M.; Mackiewicz-

Talarczyk, M.:Handbook of Natural

Fibres, Band 2, 2. Edition,

Duxford, United Kingdom:

Woodhead Publishing, 2020

[Nov01] Nova-Institut (Ed.)

Das kleineHanf-Lexikon

Die Werkstatt (Göttingen), 2001

[Opp14] Oppel A.:

Der Anbau der Baumwolle in

Abhängigkeit von Klima und

` Boden geographische Zeitschrift

20 (1914), H. 5, S. 241-257

[Tro95] Trommer, G.: Rotorspinnen,

Frankfurt am Main: Deutscher

Fachverlag, 1995

[UN15] United Nations: Transforming

our World: The 2030 Agenda

für Sustainable Development,

UN, 2015