Yogita Agrawal, Asst. Professor;

Asin M. S., Student, B.tech,

Manish Singh, Student, B.tech,

Textile Engineering,

Shri Vaishnav Institute of Textile

Technology

Abstract

In this project, the samples are taken from ring frame to the winding machine at three different winding speeds keeping the yarn tension constant. Here the half bobbin is wound into the cone and then both of the samples are tested using Uster evenness tester. The sample which shows best result will be selected as the best winding speed.

Simultaneously, the samples are taken from ring fame to the winding machine at three different

yarn tension with constant winding speed, then the following steps are done same as mentioned in the

previous paragraph. All the steps performed with proper result and conclusion is mentioned in this

work.

1.0 Introduction

In our different units, auto winding is performed at different types of Autoconer machines. They have certain differences in technical features and qualitative control systems during high-speed

winding.

2.0 Objective

To check the wholesome affect of these different technologies on yarn quality changes at cone stage, a study was conducted under control condition.

3.0 Methodology

3.1 At differen speeds and same yarn tension

1) Study was conducted in 30 Ne P/C 48/52 of unit-I, R/F 16. Spinning positions kept same for all the samples.

2) Full R/F bobbin tested at UT-4 to get the IPI at bobbin stage.

3) Each set of bobbins (10 bobbins) are converted into cones in A/C No. 1 at different speeds 1400

mpm,1500 mpm & 1600 mpm at same yarn tension.

4) All cones tested at UT-4 to get the IPI at bobbin stage.

3.1.1 Results & discussion

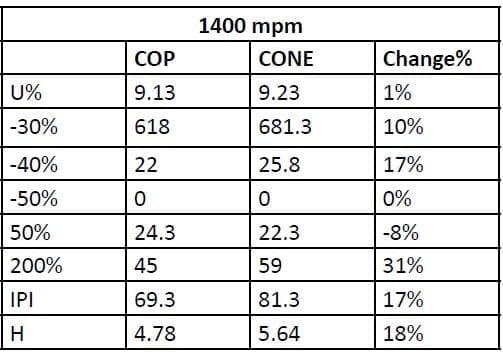

Table no. 1.1 : Yarn properties at 1400 mpm

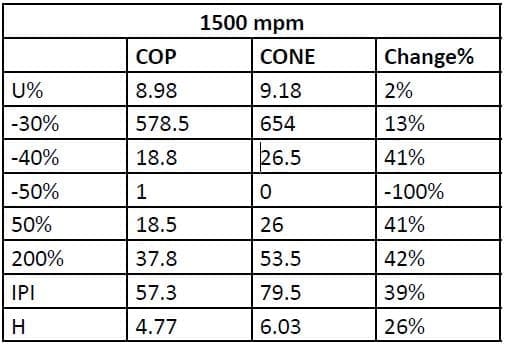

Table no. 1.2 : Yarn properties at 1500 mpm

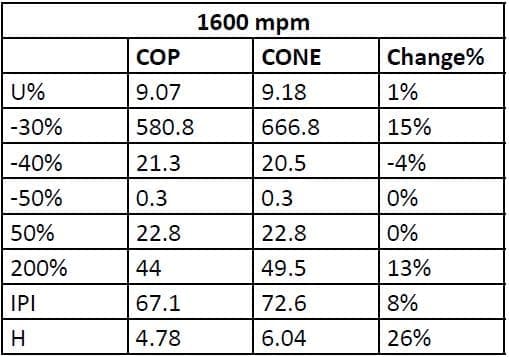

1) By the observing the above tables, we will choose 1400 mpm because it shows more better results than 1500 mpm & 1600 mpm.

3.2 At Different Yarn Tension and same Speed

1) Study was conducted in 30 30 Ne P/C 48/52 of unit-I, R/F 16. Spinning positions kept same for all

the samples.

2) Full R/F bobbin tested at UT-4 to get the IPI at bobbin stage.

3) Each set of bobbins (10 bobbins) are converted into cones in A/C no 1 at different tension 250 cN,

260 cN & 270 cN at same speed 1450 mpm.

4) All cones tested at UT-4 to get the IPI at bobbin stage.

3.2.1 Results & discussion

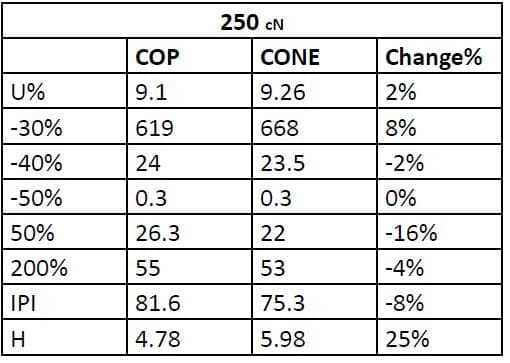

Table no. 1.4 : Yarn properties at 250 cN

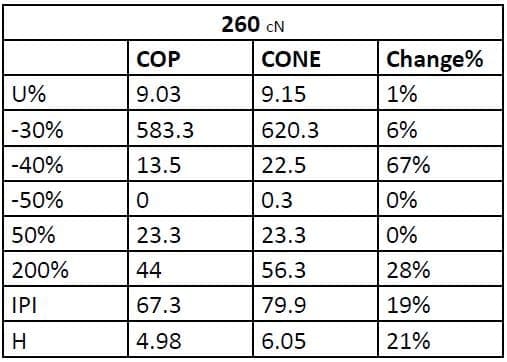

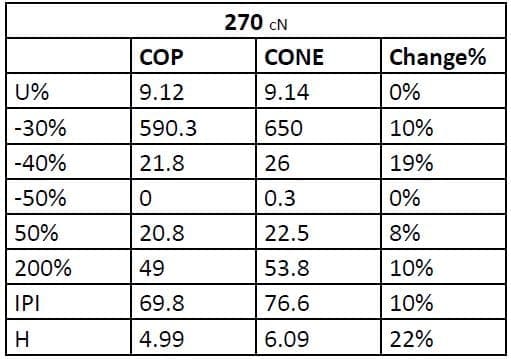

Table no. 1.5 : Yarn properties at 260 cN

1) By the observing the above tables, we will choose 250 cN& 260 cN tension as it shows better results than 270 cN tension.

2) Now we need to decide which is the best among these two tensions.

4.0 Determine the best result by finding out cone density

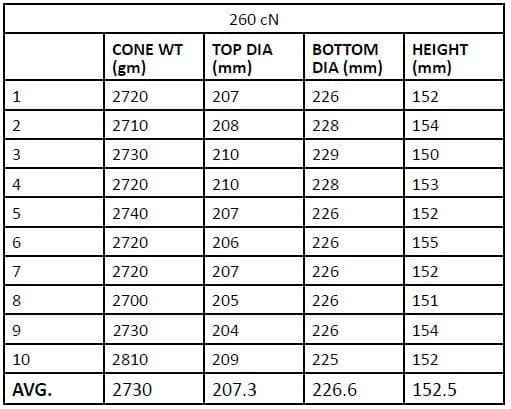

1) In autoconer, select 10 drums and set the yarn tension at 260 cN by keeping the speed constant.

2) Feed the empty cones in the respective drums and mark them according to the order.

3) Wait until the doff gets completed.

4) Observe and record the following measurements like weight, top and diameter & height. Also note

the top and bottom diameter & weight of empty cone.

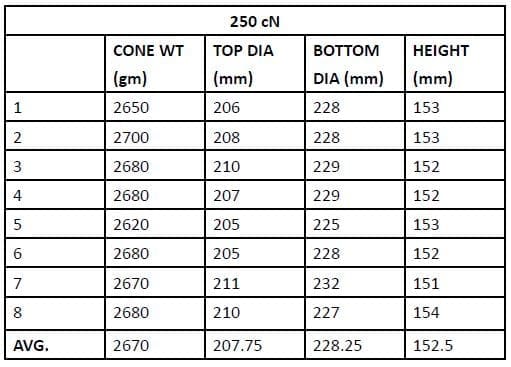

5) Do the same as described above for yarn tension 250 cN.

1 Result & Calculation

Table no. 1.7 : Cone dimensions at 260 cN

A) FOR 260 cN

empty cone top diameter = 4 cm (d1)

empty cone bottom diameter = 6.2 cm (d2)

empty cone weight = 39 g

full cone top diameter = 20.73 cm (D1)

full cone bottom diameter = 22.66 cm (D2)

height = 15.25 cm (h)

yarn weight = 2730-39 = 2691 gm

volume = π x h x ((D12+ D22+D1xD2)

– (d12+ d22+d1xd2))/12

= π x 15.25 x ((20.732+ 2.662+20.73×22.66)-

(42+ 6.22+4×6.2))/12

= 5324.75 cm3

density = 2691/5324.75 = 0.505 gm/cm3

A) FOR 250 cN

empty cone top diameter = 4 cm (d1)

empty cone bottom diameter = 6.2 cm (d2)

empty cone weight = 39 g

full cone top diameter = 20.77 cm (D1)

full cone bottom diameter = 22.82 cm (D2)

height = 15.25 cm (h)

yarn weight = 2670-39 = 2631 gm

volume = π x h x ((D12+D22+D1xD2)-

(d12+d22+d1xd2))/12

= π x 15.25 x (20.772+22.822+20.77×22.82)-

` (42+6.22+4×6.2))/12

= 5377.29 cm3

density = 2631/5377.29= 0.489 gm/cm3

5.0 Conclusion

1) The above results show that the cone formed with tension 250 cN has a good cone density and can easily fitted in carton box of dimensions 25.5 x 17.5 x 20.25 inches.

2) So, we will choose 250 cN tension as it shows better results in U%, IPI and hairiness and ood cone

density.