Kartick K Samanta, S Saxena, S Basak, and S K Chattopadhyay

Chemical and Bio-chemical Processing Division

Central Institute for Research on Cotton Technology

Adenwala Road, Matunga, Mumbai – 400019, India.

*Corresponding author: karticksamanta@gmail.com

Chemical processing of textile is important improve its aesthetic and functional value. However, during the wet chemical processing of textile, industry causes significant water and air pollution towards the padding, drying, curing and post washing operation. The cost of final product also increases due to the multiple drying operations and effluent treatments. Several technological advancements have been demonstrated in textile to reduce the consumption of water as well as effluents production, such as spray and foam finishing, digital printing and low material to liquor processing.

In this context, CIRCOT propose plasma technology, that can be used for water-free textile processing and finishing by modifying the fibre surface at nano-meter level. Unlike bulk modification of textile by conventional process, surface modification of textile using plasma can be utilized to develop value added products by minimal usage chemical and energy. Plasma is partially ionized gas composed of many types of species, such as positive and negative ions, electrons, neutrals, excited molecules, photons and UV light. It also bears potential for the development of valued added home, apparel and technical textile at lower cost, while addressing the environment issue. . The surface modification technique is obligated to restrict the modification in the first few atomic layers of the fibre surface, while keeping bulk properties unaltered. Plasma can survive over a wide range of temperature and pressure. The lightning bolt and solar corona are the examples of plasma in nature with quite high temeratures (>1500 °C), hence cannot be used for textile processing. In contrast, cold plasma (low temperature plasma), plasma with bulk temperature of 20-250 °C, can be used for surface modification of textile substrates.

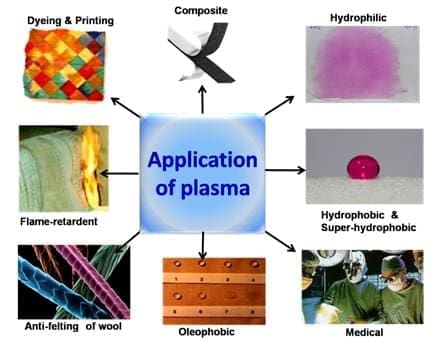

Surface modification of textile using plasma can be carried out using non-polymerizing gases (small molecule), such as oxygen (O2), nitrogen (N2), air, argon (Ar), helium (He) and big molecules such as vinyl, hydroxyl, carbonyl, carboxyl, acrylate or fluorocarbon based precursor for surface activation, cleaning, oxidation, changes in surface energy, increases in surface roughness/area, etching, coating/deposition, and creation of nano-structures. These, in turn, help in improving the textile properties in terms of water absorbency, wetting, wicking, oil absorbency, rate of dyeing, printing, adhesion, antistatic, anti-felting, water repellent, oil repellent, UV protectiveness, and antimicrobial. The main advantages of plasma processing of textile are (i) liquid-free dry single step operation, (ii) required minimal amount of chemicals, (iii) cost effective in terms of time and temperature, (iv) imparted functionality independent of substrate chemistry, and (vi) environment friendly. Atmospheric pressure plasma is preferred over low pressure plasma due its advantages of continuous process, lower treatment time and rapid production.

Application of plasma for textile processing and finishing

PROVEN & EXISTING APPLICATIONS OF PLASMA

The effect of atmospheric pressure cold plasma in the improvement of hydrophilic property was measured in terms of water absorbency time in the nylon and polyester woven fabrics [Samanta et al, 2009]. It was observed that a water droplet took 540 s to spread over an area of 3.79 cm2 in the untreated nylon sample, whereas it took only 1.1 s in the 60 s helium (He) plasma treated sample. In the polyester sample, the water absorbency time was reduced from 700 s to 6.7 s in the untreated and He plasma treated samples respectively. Absorption and spreading of water was very slow in the untreated sample because of absence of polar groups in the polymer back bone. However, after plasma treatment, the surface energy of the samples was found to increase significantly due to the generation of hydrophilic groups. Plasma treatment was also utilized to improve oil absorbency in the various textile substrates [Samanta et al, 2009]. A drop of mustard oil was placed on the fabric, and time was measured to spread over a specified area. In all plasma treated samples, there was a significant improvement in oil absorbency. In nylon, oil spreading time decreased from 152 s to 52 s in the untreated to 60 s helium plasma treated samples, respectively. Similar results were also found when the samples were plasma treated in the presence of argon, oxygen and air gases. Plasma treatment helped to reduce oil spreading time approximately by half to one third compared to untreated sample. Similar to nylon, oil spreading time in the polyester woven fabrics also decreased from 28.6 min in the untreated sample to 2.8 min in the 60 s He plasma treated sample.

It was also interesting to observe that even on cotton textile, oil spreading time decreased from 59.5 s in the untreated sample to 30.4 s in the plasma treated sample. Atomic force microscope (AFM) images showed that the untreated sample has smooth surface morphology. After the plasma treatment, vertical channel-like features with dimensions of <200 nm in nylon and horizontal channel-like features of ~100 nm in polyester were easily visible due to the bombardment high energy plasma species. The formation of such channels upon plasma treatment in the plasma treated nylon and polyester have increased effective capillary radius resulting in better absorption and spreading of water and oil. In the untreated cotton textile, better oil absorption was due to presence of textured and convoluted structure, and upon plasma treatment these features might have enhanced further. Improvement in oil absorbency of textile substrates would have the possible application in cleaning of surfaces contaminated with oil in the metal industry, household cleansers, and cosmetics. Plasma processing of textile is carried out in dry state hence adoption of such emerging technologies would help to develop value added textiles at lower cost, while addressing the environmental issues.

Reference:

Samanta K K, Jassal M , Agrawal A K (2009) Improvement in water and oil absorbency of textile substrate by atmospheric pressure cold plasma treatment. Surf Coat Technol. 203:1336-1342