MR.S. CHAKRABARTY, SECRETARY GENERAL

TEXTILE MACHINERY MANUFACTURERS’ ASSOCIATION (INDIA)

The Indian Textile Industry (TI) is critically important to the Indian economy as it contributes 4% to India’s GDP, 14% to India’s Industrial production and 17% to India’s export earnings. Decades ago, it was responsible for 33% of India’s export earnings. It is needless to mention that the Indian TI is the largest employer after agriculture employing 35 million people. There was an expectation that India’s textile and apparel industry (domestic + export) would grow from US$ 70 million to US$ 220 million by 2020. In order to help the TI to grow in the expected manner, it is essential that there is a strong Indian Textile Engineering Industry (TEI) which is capable of producing all types of textile machinery qualitatively and quantitatively to make the textile industry competitive in the world market. The domestic TEI should provide state-of-the-art textile engineering solutions to meet the true growth potential of the Indian textile industry.

The future Textile Policy should be- to facilitate unhindered growth of the textile industry with a balanced long term policy right from the raw material to the finished products in a holistic manner. In the past, it was observed that there had been kneejerk reactions from the Government for different sectors of the textile industry which resulted in imbalance and hampered the growth. Therefore right from the cultivation of cotton, production of cotton, its ginning, other raw materials, spinning to the garmenting, a holistic approach needs to be made.

Some firm policies would be needed for import and export of cotton and yarn which should not be altered except under extraneous emergent circumstances.

All sectors of the domestic textile industry should be given complete support to face the international challenges. Every sector needs to get appropriate incentives and financial assistance in a balanced manner for optimization of the overall growth. The industry must have all its inputs such as raw material, consumables, machinery, power and skilled labour, uninterruptedly at reasonable cost.

We normally compare India with other countries particularly China and say that why we cannot make ourselves competitive and export oriented like China. The difference between the Indian textile industry and Chinese textile industry is so large and it is not very clear whether we would be in a position to reach the level of 50% of Chinese textile industry. While India has 34 million working spindles, China has above 120 million spindles. In the case of shuttleless looms, we have hardly 1,30,000 shuttleless looms as against 7.20 lakh shuttleless looms in China. The textile production is hardly 10% of the Chinese production of US$ 700 billion. In case of textile machinery our production is at US$ 1 billion as against approximately US$ 10 billion of China. China does not import second hand machinery whether it is textile or not while in India such machinery is freely permitted without any restriction. China forced the foreign/European machinery manufacturers to set up their manufacturing facility. As a result, today China is the largest producer of textile machinery producing entire range of hi-tech machinery. Whereas in India, we do not have the entire range of hi-tech machinery. While we are very good in Ginning and Spinning machines, good in Weaving Preparatory and Processing Machines. We cannot produce hi-tech weaving machinery, knitting machinery, garment making machinery, non-woven machinery and other technical textile machinery.

The Textile Engineering Industry which was the prime mover for the textile industry during 60s, 70s and 80s suffered a serious setback during 90s after the liberalization of import and trade policies of the Government. As a matter of fact, the entire capital goods sector per say was severely affected due to the sudden liberalization.

If we look at the developed countries, we will find that the technology and engineering was the prime mover. Every such country has helped their machinery manufacturing sector to grow consistently.However, during the post era of liberalization, the country moved towards import oriented growth, thereby creating a trade imbalance.

There is an absolute need that the domestic textile engineering industry should grow, compete and export. It should be able to provide strong support to the Indian textile industry to make it vibrant and competitive. It should acquire technological strength in all sectors as in the case of Ginning and Spinning through FDI and R&D and meet 70-75% of the demand of Indian textile industry for high tech machinery from the current position of 40-45%. India should become a manufacturing hub for textile machinery, parts & components and accessories contributing further to employment generation and GDP.

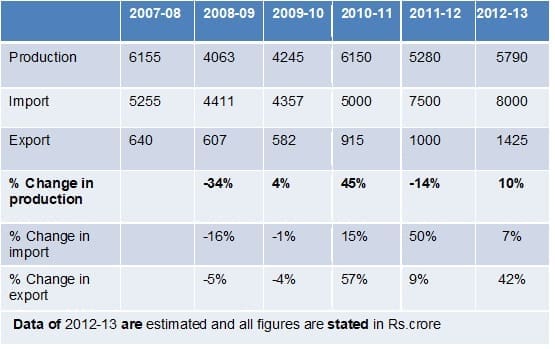

At present, the TEI consist of more than 1,400 units with a total investment of Rs.7,800 crores. The total capacity is only Rs.9,100crore and it provides direct/indirect employment to over 250,000 people. More than 85% of the units are SMEs. The TEI is mainly dependent on the domestic demand as a result, itsuffers periodic highs and lows which can be seen from the following statement

TEI – An Update

The TEI is suffering from the issues like lack of level playing field.Duties and taxes are not compensated against imports.Largenumber of SMEs does not have access to funds, lack of modernization and technology upgradation, lack of research & development and skill upgradation, lack of policy supports from the Government. There is an absolute need for modernization of the SMEs in the Textile Engineering Industry. The modernization fund with interest subvention and upfront margin money subsidy is absolutely necessary to upgrade the manufacturing technology of the SMEs to achieve the long term goal. This could be in line with the TUFS for the textile industry.

The domestic machinery manufacturers should be encouraged to manufacture high tech machinery for the weaving sector. For this purpose, the import of parts/components spares & accessories of shuttleless looms including electronic dobby, electronic jacquard should be allowed at nil duty without any condition/restriction whatsoever. This would facilitate fast development of high tech shuttleless looms in the country. It should be kept in mind that such critical parts and components if imported cannot be used anywhere other than in the shuttlelessloom itself. Similar approaches should be under taken for the manufacture of other high tech machines which are not being manufactured indigenously.

Present infrastructure for R&D is inadequate for the promotion of R&D.There should be more infrastructure facility at different clusters in the country in the form of Common Facility Centres. A fund should be created for giving grants for acquisition of technical knowhow from overseas. This would facilitate the availability of technology for high tech machinery.

The present policy of the Government does not attract FDI in the textile engineering sector specifically weaving machinery sector,the primaryreason being the import of second hand machinery in large numbers. It should be kept in mind that no foreign machinery maker would like to compete with its own machinery which is coming in second hand/used condition. We cannot expect any FDI so long as this policy remains.

China produces low tech, medium tech as well as high tech textile machinery. If we desire to manufacture high tech textile machinery, we need to dis-incentivise the import of low tech machinery from China. It is needless to point out that unless the domestic textile machinery makers are able to compete with the Chinese machinery, it would be a futile attempt for them to go in for production of high tech machinery.

Competitiveness of an industry comes with a level playing field.Unless the domestic manufacturers are confident to compete, there would be no more investments.Therefore, the future textile policy must have inbuilt provisions for the technological and machinery development in the country so that the cost of investment of the textile industry remains at a reasonable level. One thing is sure, without a vibrant Textile Engineering Industry there could not be a jubilant Textile Industry.