NSK SRINIVASAN 1 & HASMUKH SHAH 2

UMTA Management & Texstyles Academy, Vapi, Gujarat, India nsk_sriya@yahoo.com textiles.vapi@gmail.com

Introduction

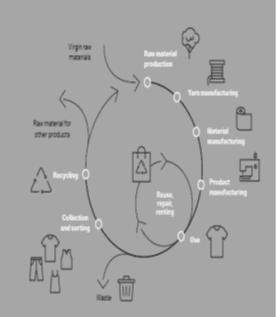

Circular economy is a recent economic model that has emerged as a response to the new needs of society and our planet

Circular economy is the sustainable future .The circular economy model has recently gained a lot of attention worldwide from scientists, business people and authorities. A circular economy (often referred to simply as circularity) is an economic system aimed at eliminating waste and the continual use of resources.

Circular systems employ reuse, sharing, repair, refurbishment, remanufacturing and recycling to create a close-loop system, minimizing the use of resource inputs and the creation of waste, pollution and carbon emissions.

The circular economy aims to keep products, equipment and infrastructure in use for longer, thus improving the productivity of these resources. In the textile and fashion industry, companies would actively utilize the circular economy as a part of their business.

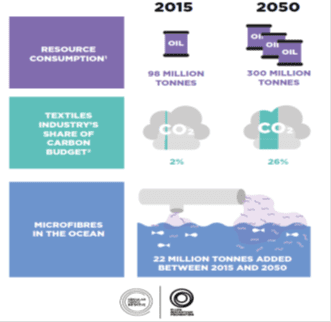

Table -2. THE NEGATIVE IMPACTS OF THE TEXTILES INDUSTRY ARE SET TO DRASTICALLY INCREASE BY 2050

1 Consumption of non-renewable resources of the textiles industry, including oil to produce synthetic fibres, fertilizers to grow cotton, and chemicals to produce, dye, and finish fibres and textiles. 2 Carbon budget based on 2 degrees scenario. Source: Circular Fibres Initiative analysis .

Table-1-At the head of the circular economy II – Solutions for textile recycling, 2018 Finnish Textile & Fashion Eteläranta ,Helsinki www.stjm.fii Table-2- A NEW TEXTILES ECONOMY: REDESIGNING FASHION’S FUTURE 2017 Ellen MacArthur Foundation, www.ellenmacarthurfoundation.org

Building a Circular Apparel Economy 1

- Increasing the use of sustainable inputs and material, Maximizing the utilization of textile & clothing, increasing the recycling of clothing as well as Boosting production through renewable inputs can be some of the major initiatives.

- Growing production & consumption trends in the textile and apparel industry highlight the opportunity in transitioning to a circular economy. Circular innovations at critical points across the value chain are increasingly available.

AMBITIONS FOR A NEW TEXTILES ECONOMY 2

- Phase out substances of concern and microfibre release

- Transform the way clothes are designed, sold, and used to break free from their increasingly disposable nature

- Radically improve recycling by transforming clothing design, collection, and reprocessing

- Make effective use of resources and move to renewable inputs

There are four principles that explain the concept of circular economy 3

1. Zero waste – Nothing is thrown away, because waste is designed out by making things for repair,

disassembly and reuse.

2. There are only two types of industrial ‘ingredients’- a) Disposable and biodegradable b) Durable and reusable

3. Entirely renewable energy in the industrial cycle- This also reduces businesses exposure to depletion of sources of energy resources.

4. Customers are no longer consumers, but users-Seek to provide access to a service instead of ownership of a good. Companies areresponsible for the product and its waste.

Benefits of a circular economy 4

Reduces the extraction of raw materials. Favors the reduction or elimination of the polluting discharges

The value that is created from labor, from capital invested in production processes and technology are maintained for long periods in the economy.

It promotes the reuse and recycling of the components of the products, offering a great opportunity and a competitive advantage to those entrepreneurs or innovators

The consumer benefit is far more durable and repairable products that are able to reduce the cost of living which allows them to have a greater purchasing power

The benefits of social and environmental welfare would also generate improvements in human health and quality of life.

Contributes to improving the quality of soil, water and air, and ultimately the planet and consequently also improves the living conditions of people.

Barriers to adopting circular economy business practices

Environmental culture. Financial barrier. Lack of government support and effective legislation. Lack of information. Administrative burden .Lack of technical skills. Lack of support from demand and supply network

What will it take to achieve a circular economy 5

Designing waste out of the manufacturing process must be cost effective and positive for the profit margins of companies

Collaboration and innovation. Consumer behavior. Government policy. Regulations. Focused investment.

Innovation Trends 6

Three powerful innovation trends that will impact the industry in the coming years, all of which are very closely related to the new circular economic model. These are

1. Digitization of products, their design, manufacturing, distribution and retail processes, consumer/end-user interaction, factories, workplaces and supply chains

2. Sustainability, circularity and resource efficiency of materials, processes and overall business operations; this trend requires transparent supply chains meeting the environmental, health and social legislation standards

3. New business and consumption models based on the sharing of productive resources and final products, servitisation, pay-per-use or subscription models, all moving us towards collaborative or sharing economy

Waste Classification

Textile waste can be generally divided as per its source into three main types

1. Post-industrial waste – a side-effect of clothing manufacture;

2. Pre-consumer waste – inferior quality garments at the manufacturing site or a retailer’s distribution center, unsold merchandise at the retail store;

3. Post-consumer waste – generated by consumers themselves: worn out, damaged or unwanted clothing.

The key challenge in handling the three types of waste is to reduce their amounts and to minimize waste that is now being incinerated or land filled.

What are circular textiles exactly? 7

Circular Textiles and Clothing essentially have 3 typical features:

1. They are recyclable (Design for Recycling). 2. A recycling system is available. 3. They are made of recycled textile material (Recycling in Design).

Strategy

We will develop a good circular strategy using the following five tools:

• Innovation capacity • Supply chain collaboration • Developing and sharing knowledge

• New business models • Financing & government policy

Circular Textiles Road Map

The Circular Textiles Road Map is a holistic approach in which key elements of the circular textiles supply chain come together. Individual parties can concentrate on one or more elements, but will always need to keep an eye on the bigger picture in order to make balanced choices. The Circular Textiles Road Map comprises six action lines:

• Circular design • Circular supply chain/cross-sectoral actions • Mechanical recycling

• Chemical recycling • Business models • Resources

Why Recycle Textiles 8

Carbon footprint reduction, Clean air preservation, Reduce energy consumption Water conservation, Woodland conservation

Textile Recycling Drives Economy

Revenue stream for recycling agencies, Creates jobs, Funds charitable initiatives Promotes small business, Encourages recycled product development, Provides affordable clothing opportunity

SMART’s Goals

Increase awareness of need to recycle textiles, Increase supply of textiles in marketplace

Decrease the amount of clothing and textiles in landfills, Offer help and expertise to government in developing programs to promote textile recycling and help find recycling company partners, Reduce cost to municipalities by reducing tipping fees associate with textile waste disposal, Funds raised by clothing collection can be used by communities for community projects, school programs and recycling education

Capture remaining 85% of textiles that are not being recycled – Donate, Recycle, Don’t Throw Away.

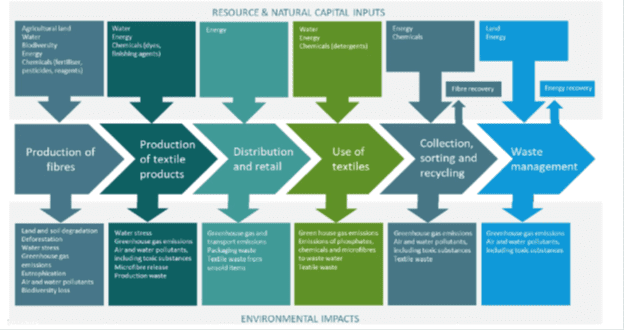

Environmental impacts across the textiles life-cycle

The environmental impact of the production and consumption of textiles reflects the high complexity and linearity of their value chain. The range of impacts varies depending on the different textiles and fibres considered, as well as the environmental and socio-economic contexts underlying the production, distribution, use, and end-of-life phase .Amongst others, environmental impacts to which the textile sector is a major contributor include the depletion of material resources and water, land use, climate change and chemicals’ toxicity.

Table 3

Reference: Table-3- Textiles and the environment in a circular economy, Eionet Report – ETC/WMGE 2019/6, November 2019, Web: wmge.eionet.europa.eu

Examples of approaches to circularity 9

Extends product life – Repair, Reuse/Resell, Remanufacturing (up cycling), Renting

Recycle – Recycling/recovery

Drivers – External pressure, Securing future resources, Value of textile waste, Marketing as a circular company, Marketing as a circular company

Inhibitors- No technology to support textile-to-textile recycling on a commercial scale, Separation of materials, Costs, Recycling of textiles must fit within sustainability framework, Recycling of textiles must fit within sustainability framework, Size and complexity of supply chain, Lack of systemic support

Enablers- Technology, Design and new materials, Collaboration, Garment collection

Needed technology – Recycling technology, Sorting technology, Innovation/digitalization

Needed systemic change – Replace linear production models/build circular business case, Collaboration, Slow and fast production systems

Global material flows analysis

The analysis of the global material flows of textile fibres is based on an aggregation of fragmented

data sets, often with varying definitions and scope. The analysis not only reveals a significant

opportunity to increase circularity and capture material value, but also highlights the need for better

reporting standards, transparency, and consolidation on a global level.

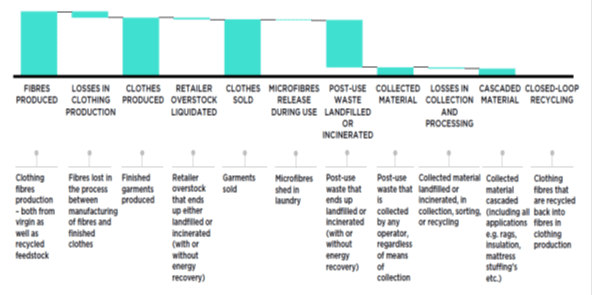

DEFINITIONS FOR OVERVIEW OF GLOBAL MATERIAL FLOWS FOR CLOTHING

Reference: Table-4- A NEW TEXTILES ECONOMY: REDESIGNING FASHION’S FUTURE

2017 Ellen MacArthur Foundation, www.ellenmacarthurfoundation.org

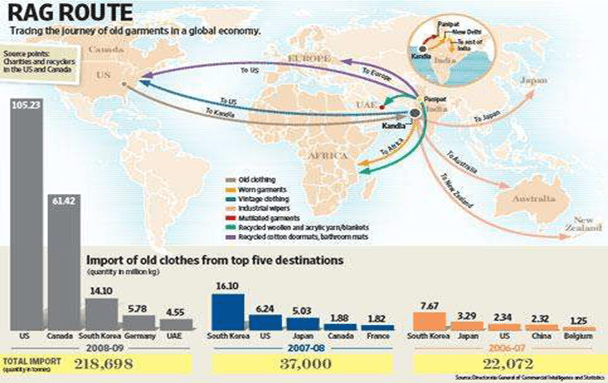

Recycling of Textiles in India

Reference : Table -5-Panipat Stories – Textile recycling, hardcore. Shirahime, CIRCULARITY MATERIALS SUPPLY CHAIN ,January 17, 2013

Panipat sources Woollen clothing from the US, Canada, the UK, Western Europe, Japan and

most of it is turned into shoddy yarn, and used to make coarse and cost effective blankets. 10

Textile Recycling Initiative in New Delhi by Goonj. The GOONJ project operates by gathering clothing which are unused from across India to subsequently recycle the materials to provide clothes, sanitary as well as some other basic amenities to people who live in communities which are poorer all over the country. The Goonj Project: Textile recycling initiative in New Delhi https://inhabitat.com/goonj-recycling-textiles-in-new-delhi/)

Recycling of textile has been a major area for Kishco Group. Items in this category are both imported into India and exported out of India to serve various industries. These materials are made up of residues of all types (cotton, acrylic, wool, polyester, nylon etc.) Kishco group https://www.kishcogroup.com/textile.html

India’s textiles recycling sector employs more than one million people and, each year, turns over around US$ 2 billion in processing some 5 million tonnes of material. 11

Recycling of Textile Wastes in Craft Clusters of India- Post-consumer textiles wastes are also up-cycled in small Indian clusters. Traditionally, fabrics from old cotton sarees are made into layers and stitched together using run stitches, to give a unique design\ effect. This product termed as “Kantha” is used for infants and children as blankets and wraps as it is soft and suitable for the Indian climatic conditions. They also use old textiles to make caps, bags and other accessories with beautiful hand embroidery. Activities like Kantha stitch on cotton fabric, Recycled caps with hand embroidery of the Bakkarwal tribes of Jammu & Kashmir, India., Patch work on old clothing in Rajasthan, India. The Chindi Rug/Chakhlo ,Godhadi and Gudri as well as Sujani Embroidery are practiced to get wealth out of waste. 10

Standards associated with waste 12

For Waste Management, Recovery or Recycling Companies

ISO 9001:2008, https://www.iso.org/iso/iso_9001_2008

For consumer safety

Öko-Tex Standard 100, looks at the potential harm of substances in raw materials as well as finished products, and every stage in between:

For products made of recycled materials

Global Recycled Standard, intended for companies that are making and/or selling products with recycled content. Applies to the full supply chain and addresses traceability, environmental principles, social requirements, and labeling:

Recycled Content Standards

For products designed for end of life

Cradle-to-Cradle Standard, a multi-attribute eco-label that assesses a product’s safety to humans and the environment and design for future life cycles: https://www.mbdc.com/detail.aspx?linkid=2&sublink=8

Who’s Who in the Waste World? 12

BIR – The Bureau of International Recycling www.bir.org/industry/textiles-

European Outdoor Group – Sustainability Working Group – End of Life Task Group https://www.europeanoutdoorgroup.com/sustainability-csr

ISWA – International Solid Waste Association www.iswa.org

NICE – The Nordic Initiative Clean & Ethical www.nicefashion.org/en/featured-projects/textile-waste/index.html

.

WRAP– The Waste & Resources Action Programme www.defra.gov.uk/publications/files/pb13461-clothing-actionplan-110518.pdf

SMART – Secondary Materials and Recycled Textiles Association www.SMARTasn.org

Reference -9. Textile Exchange Fast Facts, Textile Exchange 2012

Going Forward

There is a great need for developing a good circular strategy involving • Innovation capacity • Supply chain collaboration • Developing and sharing knowledge • New business models • Financing & government policy.

While reusing and recycling textiles and apparels focus should be more for value addition and extended reuse for availing the total benefits of recycling. Awareness and training would help in this area. For fuller and effective utilization of waste and reuse materials , Research Organizations , Industry , Trade Body , Governmental Agencies and Social Organizations have to work collectively for positive outcomes.

Circular economy including Textile Circular Economy is a useful tool for meeting to the new needs of society and our planet.

A circular economy designs waste out of the economic system. This means designing products for longevity with repairability in mind so that materials can be easily disassembled and recycled. In the circular economy, the goods of today become the inputs for other products in the future.

The enablers are Technology, Design and new materials, Collaboration, Garment collection etc.

Standards and Consumer Safety should be taken into account while product recycling meant for extended reuse and value addition.

Textile Recycling Drives Economy – Revenue stream for recycling agencies, Creates jobs, Funds charitable initiatives Promotes small business, Encourages recycled product development, Provides affordable clothing opportunity

Reference:

1. A presentation on Building a circular apparel economy in India ,CAIF The Circular Apparel Innovation Factory, circularinnovations@intellecap.com

2. A NEW TEXTILES ECONOMY: REDESIGNING FASHION’S FUTURE 2017 Ellen MacArthur Foundation, www.ellenmacarthurfoundation.org

3. Promotion of Circular Economy in the Mexican Apparel industry, CEMDA, CDMX, June 2019

4. Circular Economy: Application in the textile industry, Patricia Herrero Rodríguez

Degree in Finance and Accounting Academic year 2016/17 Supervised by María Ángeles Fernández Izquierdo

5. Intentional Design: Embracing the Circular Economy, Global Thematic Research, Cornerstone Capital Group, www.cornerstonecapinc.com | info@cornerstonecapinc.com

6. CIRCULAR ECONOMY — CHALLENGES FOR THE TEXTILE AND CLOTHING INDUSTRY Małgorzata Koszewska Lodz University of Technology, Faculty of Management and Production Engineering, Department of Production Management and Logistics, Wolczanska 215, 90-924 Lodz, Poland malgorzata.koszewska@p.lodz.pl

7.On the roads towards Circular Textiles, road Map for the Dutch Textile Industry . Dutch Circular Textiles Road Map, www.afvalcirculair.nl www.modint.nl

8. A presentation on Textile Recycling by SMART – Secondary Materials and Recycled Textiles Association www.SMARTasn.org

9- Applying circular economy to the fashion industry in Scandinavia through

textile-to-textile recycling ,Ida Marie Sandvik ,Monash University, 23 October 2017.

10. Recycling of Textiles in India, Bairagi N,Department of Knitwear Design, National Institute of Fashion Technology, Bengaluru, India. Textile Science & Engineering, 2014

11. Textiles recycling: Rising pressure on India’s Recyclers, RECYCLING magazine , October 2017 https://www.recycling-magazine.com

12. Textile Exchange Fast Facts, Textile Exchange 2012