Mechanical Bonded Fabrics essentially involves the strengthening of webs through the physical entanglement of fibres. Mechanical methods include needlepunching, hydroentangling and stitch bonding.

Non-woven fabric is a fabric like material made from staple fibre (short) and long fibres (continuous long), bonded together by chemical, mechanical, heat or solvent treatment.

Why bonding?

- All fibres (Natural, Manmade) always have to achieve some specific requirements, the fiber choice with the appropriate application of bonding becomes essential.

- This can be achieved by comparing the requirements to be met together with their obtained results from individual fibre.

Non-woven fabric bonding can be defined as:

- Mechanical Bonding

- Chemical Bonding

- Thermal Bonding

- Bonding of Spun Laid Web

Mechanical Bonding

Mechanical bonding is when the fibres are not altered by either heat or chemicals and are instead bonded by an alternate method.

Hydro-Entanglement bonding (also called spun lace), bonds the fibers by mechanically intertwining the fibres with water jets. Similar to spunlace there is also needle punching/needle felting which uses needles to intertwine the fibers as opposed to the water jets.

Also, there is ultrasonic pattern bonding for use in materials that need to be a bit softer than other non-wovens.

Mechanical Bonding Types

- Stitch Bonding

- Needle Punch Technique

- Hydro-Entanglement

Needle Punching

- Needle-punching is a non-woven process by which the fibres are mechanically entangled to produce a non-woven fabric by repeated penetration of barbed needles through a preformed dry fibrous web.

- More importantly, Needles are the heart of the needle-punching process.

- The machine which accomplishes this process is known as needle loom.

Applications:

- Geosynthetics

- Filter media

- Synthetic leather

- Waddings and Paddings

- Floor coverings

- Automotive fabrics

- Insulation

- Blankets

- Wipes

- Roofing

Hydro Entanglement

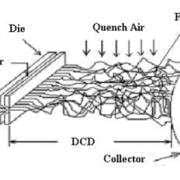

Hydroentanglement, spun lacing, hydraulic entanglement, and water jet needling are synonymous terms describing the process of mechanically bonding the fibres in a web by means of high energy water jets. Moreover, the machine which accomplishes this is known as hydroentanglement or Spun lace machine.

Applications:

- Wipes

- Surgical fabrics

- Medical gauge

- Filter cloths

- Artificial leather

- Automotive fabrics

- Linings and clothes, etc.

Stitch bonding

Stitch-bonding is a process by which fibre webs and/or yarns are bonded together by stitching with continuous filament or staple yarn, creating a series of loops that hold the web together.

Stitch bond is a non-woven construction where the fabric is formed by stitching or knitting the fibres to form a fabric with the appearance of a knit fabric. However, in the most common cases it involves warp knitting of yarns through a fibrous mat. It can also be knitted by fibres without yarns or knitting of yarns around laid warp and filling yarns which do not interlace with each other.

Applications:

- Soft furnishings, upholstery fabrics for mattresses and blankets.

- Transportation cloth.

- Cleaning cloths, fabrics for hygiene and sanitary purposes.

- Secondary carpet backing.

- Lining fabrics, interlining for shoes and apparel.

- Adhesive tapes (e.g., those used for harnessing electric cables in automobiles)

- Insulating materials.

- Geo textiles, filter fabrics.