EFFECT OF DIFFERENT WEAVES ON THERMAL RESISTANCE PROPERTIES SHRTING COTTON FABRIC

- G. Shrivas and L.G. Patil

Department of Textiles

D.K.T.E. Society’s Textile and Engineering Institute, “Rajwada”, Ichalkaranji-416115 Maharashtra, India

Email*:rashmi.shrivas89@gmail.com

Abstract

This paper represents the new research on various comfort aspects of woven cotton fabric. This paper aims to investigate the relationship between different fabric weave structure (weaves) and its comfort properties. In this connection seven different basic weaves as well as derivatives of basic weave structure were studied. Comfort properties of fabric in terms of air permeability and thermal resistance were determined. It was found that the fabric with plain weave structure showed the highest thermal resistance making it suitable for cold climatic conditions. The crepe and 2/2 matt weave depicted the lowest thermal resistance which makes it appropriate for hot climatic conditions.

Keywords: Fabric Structure, comfort, weaves, thermal resistance, air permeability, etc.

Introduction

Clothing is an integral part of human life. The primary role of clothing is to form a layer/s of barriers that protects the body against unsuitable physical environments. This protection of body fulfill number of functions like maintaining the right thermal environment to the body, which is essential for its survival and preventing the body from being injured by abrasion, radiation, wind, electricity, chemical and microbiological substances. These traditionally classified functions of clothing clearly indicate that it plays a very important role at the interface between human body and its surrounding environment in determining the subjective perception of comfort status of wearer.[1]

Clothing has a number of functions like adornment, status, modesty & protection. To be competitive, modern clothing besides having good mechanical and technological properties and being of easy care, must possess good comfort characteristics. Comfort has totally replaced the durability as far as the selection of garment is concerned [1].

- Factors Influencing Comfort Properties of Textiles

The comfort is considered as a fundamental property when a textile product is valued. The comfort characteristics of fabrics mainly depend on the structure, type of row material used, weight, moisture absorption, heat transmission and skin perception.[11]

The clothing system which is suitable for one climate may not be suitable for another climate. For example, good thermal insulation properties are needed for clothing which is to be worn in cold climates. The thermal insulation of textiles depends on number of factors namely thickness, number of layers, drape, fiber density, flexibility of layers and adequacy of closures [1]. The main factors which are affect to the comfort properties of textiles are:

- Fabric Structure

- Yarn structure

- Fiber

From the comfort point of view, the suitable fabric must be developed by textile technologist through the proper selection of fiber content, yarn and fabric construction techniques and finishing treatments. The fabric properties depend on fiber properties, yarn structure, fabric structure and the mechanical and chemical finishing given to fabric.

1.2 Thermal comfort

Thermal comfort of a clothing system is associated with the thermal balance of the body and its thermoregulatory responses to the dynamic interactions with the clothing and the environment. It is necessary to design fabrics with necessary thermal properties for a specific end use. In actual wearing condition, the transmission of moisture and heat through the clothing system take place in steady state, but is continuously exposed to transients in physical activity and environmental conditions [11].

Need of thermal comfort

Human body tries to maintain a constant core temperature that is 37.4ᵒC. The actual value of this temperature may vary slightly from person to person but it is always in a narrow range. The comfortable surrounding environment temperature for human body in India is 21ᵒC. When temperature is more or less than this, body feels discomfort as a result human body needs some external agency to maintain this temperature and clothing is one of the most common devices to provide comfort in this regard. The body must be kept in thermal balance in order to maintain the required comfort level; the metabolic heat generated together with the heat received from external sources must be matched by the loss from the body of an equivalent amount of heat. If the heat gain and the heat loss are not in balance then the body temperature will either rise or fall, leading to a serious threat to life [3].

Factor Affecting the Thermal Performance of Fabrics

There are several factors which affects the thermal properties of fabric among which thermal insulation plays vital role in preventing heat loss from body. A. Gericke and J. van der Pol [4] stated that thermal comfort is influenced by textile fabric properties such as thermal resistance. Research carried out by H. N. Yoon and A. Buckley [5] with series of polyester, cotton, and polyester/cotton blend fabrics concluded that both the fabric construction and the constituent fiber properties affect thermal transport. Further they stated that thermal insulation, air permeability, and water vapor transmission rate are dependent mainly on the fabric geometrical parameters like thickness and porosity etc. S. Gunesoglu et al [6] found that the thermal protective performance increases with the entrapped air inside the fabric in both convective and radiant exposures. Frydrych I. et al [7] studied thermal insulation properties of fabrics made of natural and manmade cellulose fibers and they found that the type of raw material and fabric structure influences the properties of the finished goods. They also stated that, there are many possibilities to create fabric with properties which influence their comfort and comfort properties of woven fabrics can be achieved not only by the choice of thickness or the fabric cover factor, but also by applying appropriate weaves, appropriate finishing processes and raw materials.

Fabric properties like cover factor and thickness also have an impact on the thermal comfort of the fabric. Bilska et al. [8] studied the effect of weave design on thermal comfort properties of the fabric and found that plain fabrics have the highest value of thermal resistance following their compact structure. The compactness of the structure of plain weave reduces the porosity of the fabric, which results in lower thermal conductivity; canvas weave has a better thermal conductivity due to a comparatively open structure; and twill weave has the lowest value of thermal resistance and the highest value of thermal conductivity due to its open structure which has large floats of yarns, which is the cause behind the higher porosity of the fabric.

- Material and Method

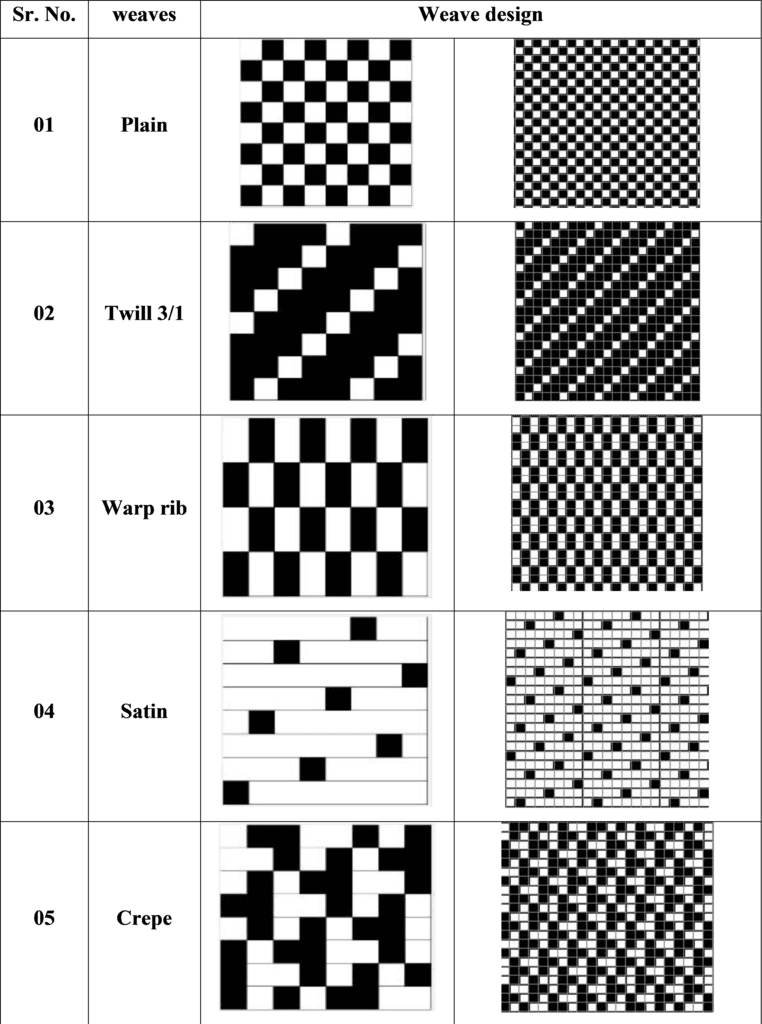

2/80 Ne cotton yarn was used both in warp and weft for manufacturing of fabric. Before manufacturing of fabric all yarn tested for tensile properties, evenness, hairiness and twist level. Seven different basic weaves as well as derivatives of basic weave structure viz. Plain, 2/2 matt, warp rib, 3/1 Twill, Herringbone twill, 8 end satin and crepe were manufactured on rapier weaving machine. The design of different fabric weaves shown in Table2.1. Finishing was followed after fabric manufacturing, with normal process sequence as followed in the shirting industry. Finished fabric specimens were evaluated for fabric thickness, areal density, air permeability and thermal resistance under standard atmospheric condition.

Table: 2.1 Fabric Structure/ weave

- Result and Discussion

- yarn properties

Table 3.1 result for the yarn properties

| Yarn characteristics | Cotton |

| Count (Ne) | 40.3 |

| Tensile Strength (gf) | 231.41 |

| Elongation (%) | 3.45 |

| Hairiness Index | 3.1 |

| Unevenness | 7.63 |

| Twist Per Inch | 27.2 |

- Fabric Properties

Table 3.2 Fabric Properties

| Weaves | Combination | Airpermiability (Cm2/cm2.sec) | Thermal Resistance Value |

| Plain | C X C | 5.62 | 30.377 |

| Twill 3/1 | C X C | 8.716 | 28.514 |

| Warp rib | C X C | 8.716 | 28.514 |

| Satin | C X C | 10.164 | 29.112 |

| Crepe | C X C | 17.8 | 22.538 |

| HB Twill | C X C | 9.174 | 29.735 |

| Matt 2/2 | C X C | 14.35 | 24.504 |

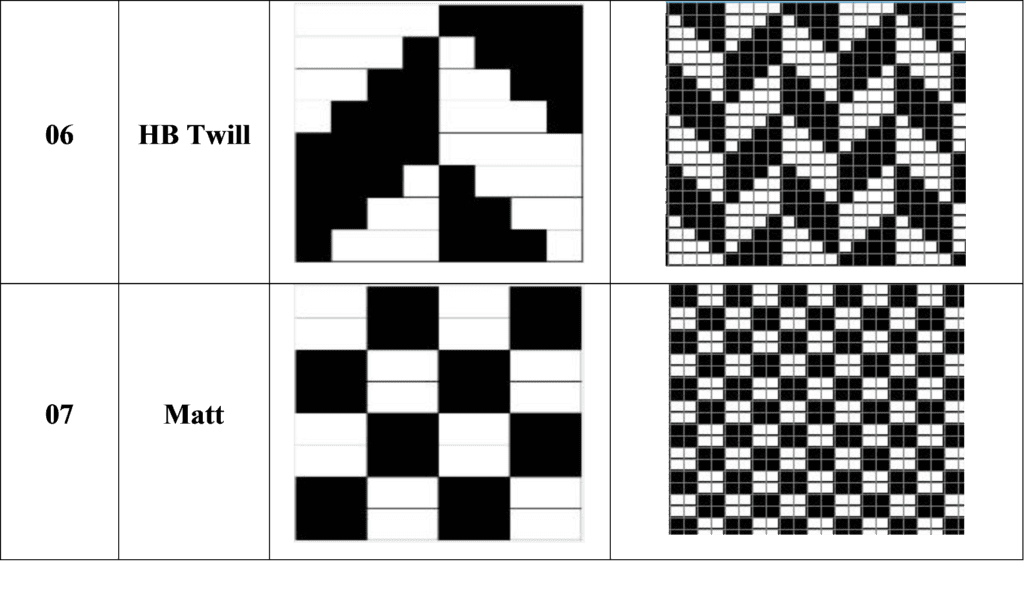

3.1 Effect of weaves on air permeability

The air permeability of a fabric is closely related to the construction characteristics of the yarns and fabrics in which large volumes are occupied by air. The air permeability of a fabric is a measure of how well it allows the passage of air through it and is defined as the volume of air passed in one second through 100 sq.mm of the fabric at a pressure difference of 10 mm of water [9]. Air permeability of fabric was tested according to [ASTM D737].

Figure 3.1 Effect of weave on Air permeability of fabrics

As shown in figure 3.1 there is a significant effect of weaves on air permeability of fabrics. The crepe weave exhibits higher air permeability values were as plain weave exhibits lower air permeability value as compare to other weaves.

The difference observed between the air permeability values of weaves were due to difference in their characteristic covering properties. For equivalent weaving parameters, crepe weave result in a looser structure as compare to other structures, other weaves which has more firm structure than crepe weave. At the other plain weave fabric has shortest float length, hence it possesses tighter fabric structure is tight. Therefore crepe fabrics show high permeability than other weaves.

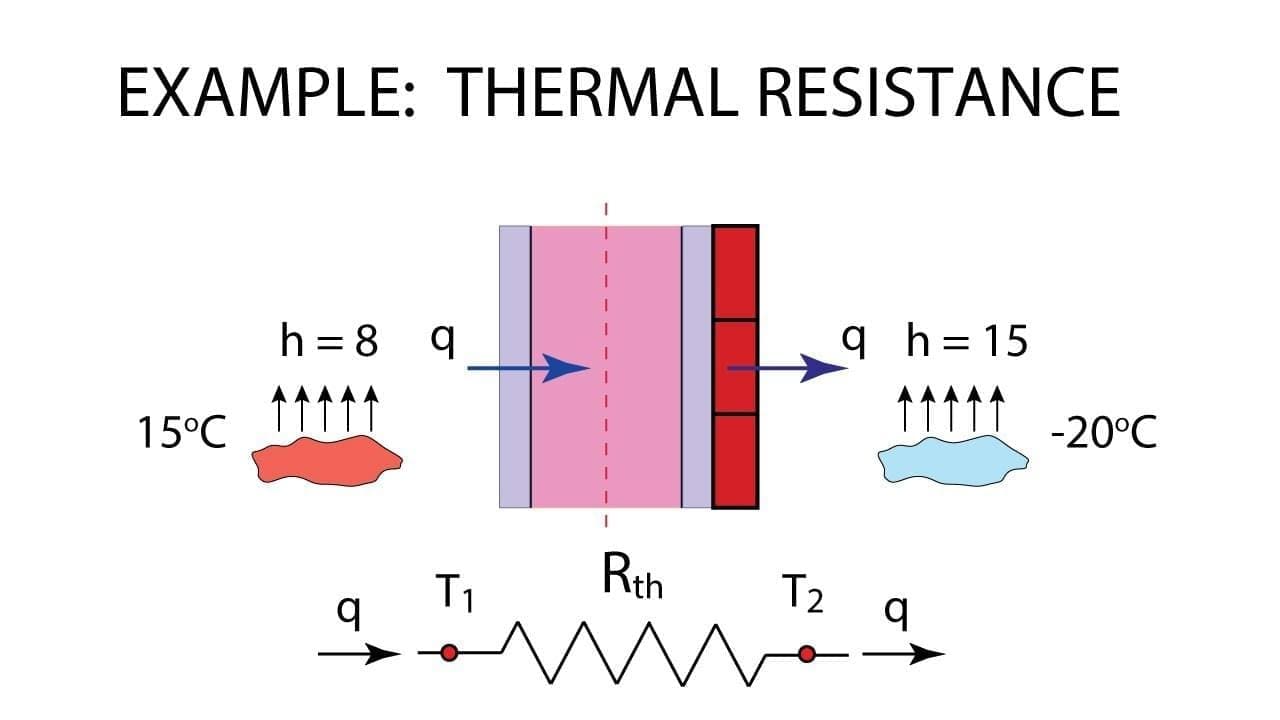

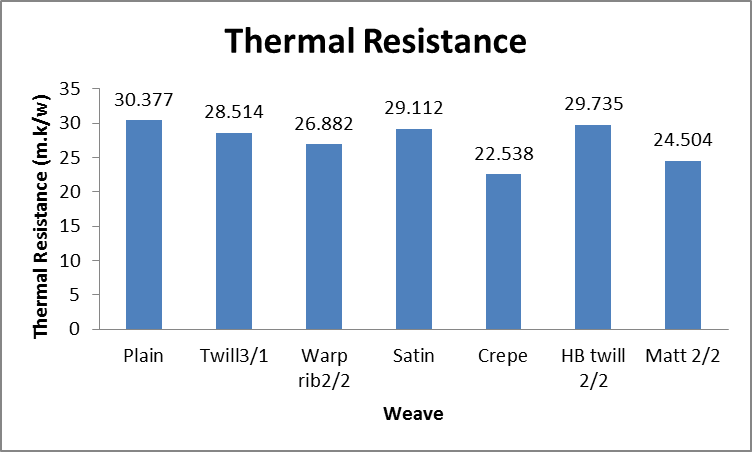

3.2 Effect of Weaves on Thermal Resistance

Thermal Resistance of fabric was tested according to ASTM D1518. The results are represented graphically and discussed below. The result shows that, a different kind of weaves has influence on thermal properties of fabrics.

Thermal resistance of a fabric refers to its ability to resist the heat flow through it. Lower the thermal resistance; the better will be the comfort for hot climatic conditions. The individual value plot for air permeability and weave structure is shown in fig.3.2.

Figure 3.2 Effect of weaves and material on the thermal resistance

The results depicted that the 1/1 plain weave has the highest thermal resistance. This is because of the fact that 1/1 plain weave has the maximum yarn interlacing points between warp and weft. High thermal resistance of this weave makes it suitable for cold climatic conditions. On the contrary, crepe and 2/2 matt weave showed the lowest thermal resistance because of its relatively less number of yarn interlacing points between warp and weft. Minimal thermal resistance of crepe and 2/2 matt weave makes it appropriate for hot climatic conditions [10].

Conclusion

The research results proved that weave structure has a statistically significant effect on the air permeability and thermal resistance of the fabric. The observed parameters contributed to the thermo-physiological comfort of the fabrics. Each weave structure has a specific pattern of yarn interlacing points between the warp and the weft. It can be concluded from the experimental results that the higher the yarn interlacing points, the lower will be the air permeability which means higher thermal resistance. The experiments illustrated that 1/1 plain weave has the highest thermal resistance among the selected weaves and hence suitable for cold climatic conditions. On the other contrary, crepe and 2/2 matt weaves demonstrated lower thermal resistance which makes it suitable for hot climatic conditions.

REFERENCES

- Gokarneshan Fabric Structure and Design, New Age International (p) Limited, Publishers, 2004. pp. 7-39.

- Mukhopadhyay, I. C. Sharma and M. Sharma. Evaluation of comfort properties of polyester-viscose suiting fabrics. Indian Journal of Fiber & Textile Research, 27, March 2002, pp. 72-76.

- B. Mhetre & N. Sarada, Effect of different weaves and picks densities on thermal properties of fabric. Journal of Textile Association, March-April 2014 pp.342-335.

- Gericke & J. van der Pol, A Comparative Study of Regenerated Bamboo, Cotton and Viscose Rayon Fabrics. Part 1: Selected Comfort Properties Journal of Family Ecology and Consumer Science, 38, 2010, pp.63-73.

- N. Yoon and A. Buckley, Improved comfort polyester part 2: mechanical and surface properties. Textile Research Journal, 54, June 1984, pp. 357-365.

- Gunesoglu, B. Meric, and C. Gunesoglu, Thermal Contact Properties of 2-Yarn Fleece Knitted Fabrics, Fibers & Textiles in Eastern Europe, 13, 2(50), April/ June 2005, pp.46-50.

- Frydrych, G. Dziworsha and J. Bilsha, Fibbers & Textiles in Eastern Europe, October/ December 2002.

- Frydrych, I., Dziworska, G. and Bilska, J. Comparative analysis of the thermal insulation properties of fabrics made of natural and man-made cellulose fibers. Fibers and Textiles in Eastern Europe, 39(4), 2002, pp. 40-44.

- P. Saville, Physical Testing of Textile, Wood Head Publishing in Textiles, Cambridge, England, T209, 2000.pp 195.

- Ahmad, F. Ahmad, A. Afzal, A. Rasheed, M. Mohsin and N. Ahmad, Effect of weave structure on thermo-physiological properties of cotton fabrics, Autex Research Journal, 15, (1), March 2015, pp.30-34.

- https://www.slideshare.net/kotharivr/comfort-properties-of-fabrics-5262746.