SYNTHETIC TEXTILE A MANMADE COMFORT EXPERIENCE

Man-made fibres (MMF) are classified into two types: synthetic and cellulosic. Synthetic fibres are made from crude oil, whereas cellulosic fibres are made from wood pulp. Polyester, acrylic, and polypropylene are the three most common synthetic staple fibres. Cellulosic fibre is viscose fibre, modal fibre, and so on. Textiles made from these synthetic and cellulosic fibres are referred to as man-made fibre textiles. Manmade fabrics have grown in popularity over the years due to their ease of maintenance, comfort, low manufacturing cost, versatility, and other benefits.

With changes in global fashion trends, demand for man-made fibre (MMF) textiles is expanding all over the world as a competitor for cotton. Currently, MMF leads global textile fibre consumption with a 72:28 ratio, which means that MMF accounts for 72 percent of total textile fibre consumption, while natural fibre accounts for the remaining 28 percent. Because of the inherent limitations of cotton and other natural fibre growth, the share of MMF has continuously increased.

According to the Textiles Intelligence Report on Forecasts of Regional and Global End-Use, demand for man-made fibres is expected to rise 3.4 percent in 2017, while demand for cotton is expected to rise only 0.5 percent. As a result of these trends, the share of man-made fibres in global end-use demand will rise from 72.5 percent to 73.0 percent, while cotton’s share will fall to 25.7 percent, with most of the overall growth occurring in developing countries, with most of this growth occurring in Asia.

The advantage of engineered fibres is that properties can be added while undesired ones can be removed. Synthetic fabrics can have unique properties, such as great absorbency or the capacity to hold pleats. Nylon, polyester, acrylic, and polyurethane are the most frequent synthetic fibres found in twentieth-century collections.

Because of their varying look and content, synthetic materials can be hard to recognize. The simplest approach to start is to look for a manufacturer’s label on the inside of the garment. For further identification, conservators use microscopic examination, burn tests, and feel tests.

Synthetic fibres are more durable than natural fibres and can easily absorb multiple hues. Furthermore, many synthetic fibres have user-friendly properties such as flexibility, waterproofing, and stain resistance. All fibres break down and wear away because of sunlight, moisture, and oils from human skin. Natural fibres are substantially more delicate than synthetic mixtures. This is primarily since natural products are biodegradable. Natural fibres are vulnerable to larval insect infestation, whereas synthetic fibres do not provide a suitable food source for fabric-damaging insects.

Many synthetic fibres are more water-resistant and stain-resistant than natural fibres. Some are even carefully treated to withstand water or stain damage.

SOME MANMADE ECOFRIENDLY FIBERS

TENCEL™ LYOCELL

TENCELTM Lyocell fabric is very soft and ideal for people with sensitive skin. It is a cellulosic fibre that has been synthesized from wood cultivated in sustainable plantations (often eucalyptus). Because no harmful chemicals are employed in the production of lyocell fibre, the process is environmentally safe on all levels. In a closed loop process, the solvent (NMMO) and water needed for its processing are recycled up to 99 percent of the time.

TENCELTM is a registered trademark of Lenzing AG.

In the United States, there is a Lenzing lyocell facility. As a result, it can be made locally. Furthermore, TENCELTM Lyocell with REFIBRATM technology allows for the use of recycled cotton scraps (up to 30% by 2020), which is very cool.

There are also plenty of novel fibres on the market created from wood from certified sustainable plantations, agricultural waste, or post-consumer cotton clothing. These are excellent but, like TENCELTM Lyocell, are now unavailable on the market.

Benefits of TENCELTM Lyocell:

- Eucalyptus grows on arid land, on which it’s impossible to plant other crops.

- Requires no irrigation water.

- Grows without the need for insecticides or pesticides.

- Lyocell is inherently eco-friendly.

- Easy to dye and wash.

- Comfortable and soft.

- Excellent moisture management.

- Biodegradable

- Wood comes from certified responsibly managed forest.

- There is a plant in Axis, AL, USA. Can be locally transformed.

BAMBOO VISCOSE

One of the most prevalent materials used in clothes is viscose. In fact, you are most likely wearing some right now! It has the potential to be a more sustainable alternative to cotton and polyester because it is created from trees and plants (such as bamboo) and can be biodegradable. The technology to produce cleaner viscose already exists.

One of the most prevalent materials used in clothes is viscose. In fact, you are most likely wearing some right now! It has the potential to be a more sustainable alternative to cotton and polyester because it is created from trees and plants (such as bamboo) and can be biodegradable. The technology to produce cleaner viscose already exists.

Viscose can be manufactured in a ‘closed-loop system’ where the toxic chemicals are captured and reused instead of being released into the environment. Bamboo is the world’s fastest growing plant. Its growing does not necessitate the use of chemical fertilizers or pesticides. Growing bamboo is now well established as a sustainable practice.

The viscose transformation process, on the other hand, necessitates the employment of toxic chemicals to convert bamboo wood pulp into viscose from bamboo (or bamboo rayon). Viscose = rayon (they are interchangeable). This method can be utilized responsibly and has a lot of promise.

Benefits of Bamboo Viscose:

- Absorb 35% more CO2 than any other forest.

- Grows without pesticide or insecticide.

- Good yield of fibre per acre.

- Viscose clothes are easy to dye & wash (wrinkle free).

- Viscose fabrics are comfortable and soft.

- Requires no irrigation water.

- Biodegradable.

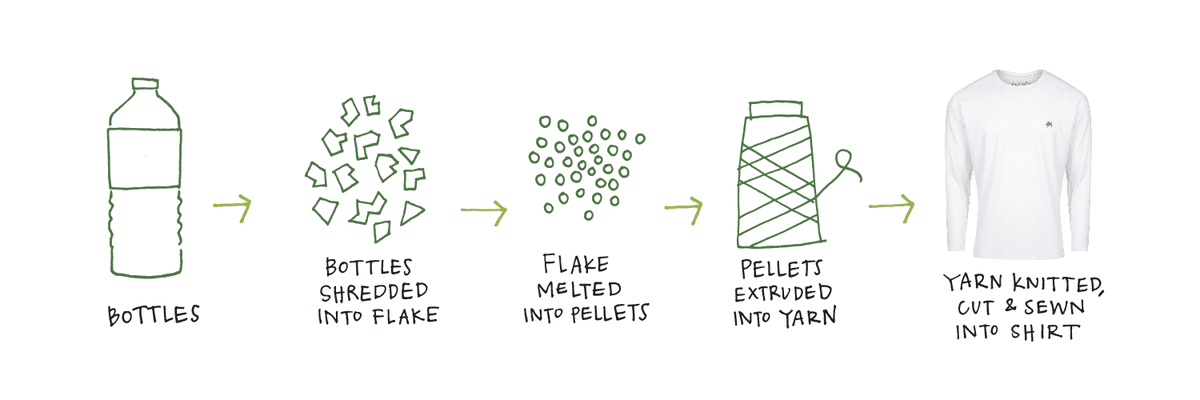

RECYCLED POLYESTER

The production of polyester fibre from recycled bottles is essentially a re-channeling of the chemical “polyethylene terephthalate,” which is also a chemical constituent in PET bottles. Polyester and PET bottles are both mostly composed of the chemical “polyethylene terephthalate.” Polyester fabrics made from recycled PET bottles have been shown to be more cost effective, as there is less heating, and energy required in the production of the polymer element.

Waste PET was depolymerized using glycolysis, and the resulting product was employed in the manufacture of the most recent polyester polyglot. This was employed for coating applications because of its superior mechanical qualities like as flexibility, impact resistance, scratch and hardness, and chemical resistance.

Environmental Benefits

- By making use of plastic waste instead of using virgin materials, recycled polyester dramatically lowers its environmental impact versus traditional polyester. Some benefits of recycled polyester:

- Reduces reliance on virgin petroleum as a raw material

- Diverts used plastic from landfills.

- Prevents used plastic from ending up in oceans and harming marine life.

- Decreases greenhouse gas emissions from creating and processing virgin polyester can be continuously recycled again and again without quality degradation.

CONCLUSION

The necessity for sustainability is essential. The need for sustainable and eco-friendly fibres is increasing. Manmade fibres have traditionally been seen to be bad for the environment. It is feasible to create sustainable synthetic fibres with desired qualities and various applications using emerging technology. More study must be done in this area. Smart textiles and technical textiles can be made with synthetic fibres. More may be said in this sector; we simply need to focus on the bright side of these fibres.

REFERENCE:

- Indian Manmade fibre textile industry_0.pdf (texmin.nic.in)

- Manmade Synthetic Fibres – Textile School

- Synthetic fiber – Wikipedia

- The Best Eco-Friendly Fibres – RespecTerre

- Dirty Fashion – Journey

Image Source:

- https://tscudo.com.au/blogs/news/what-is-recycled-polyester

- https://www.tencel.com/about

- https://www.dharmatrading.com/fabric/Bamboo-Rayon-Fabric-60.html?lnav=fabric.html

Article By:

Kshipra Gadey