Ms. Aditi Joshi*

Mrs. YogitaAgrawal** ,

Ms. ReenaKumrawat**

Mr Rajesh Dhore** *student, **faculty,

ShriVaishnav Institute of Technology and Science

Gram baroli, Sanwer Road, Indore (M.P.)

Abstract:

This paper objective is to present Lean Production (LP) as a work organisational model that fosters a sustainable work environment in garment industry. This is achievable through some lean tools and initiatives, described in the paper, that reduce the energy, water consumption, environmental waste, raw materials consumption and improve leanness and agility. Lean Production has been extensively implemented in all kind of industries, responding to customers demand with on time delivery of high quality products at reduced costs, through continuous waste elimination (e.g. over production, raw materials, energy and water more than necessary). These problems were addressed in this study by the implementation of lean tools like cellular manufacturing, single piece flow, work standardisation, just in time production etc. Lean tools bring significant changes in providing smooth process flow and productive operations which in turn gives a remarkable contribution in achieving company’s goals and giving quality products at the right time and at the right place.

Introduction

In the current era of globalisation, industries are adopting new technologies to produce goods to compete and survive in the market. The most daunting issue faced by manufacturers today is how to deliver their products or materials quickly at low cost and with good quality. One promising method for addressing this issue is the application of lean management principles and techniques. Lean management simply known as lean is production practice, which regards the use of resources for any work other than the creation of value for the end customer, is waste, and thus a target for elimination. Though there had been numerous claims on the real origin of Lean Manufacturing principles, it was generally accepted that the concept, with this background business needs to compete with efficiency and quickly respond to market needs and niches. There is no doubt that the manufacturing industry are confronted with challenges and looking for improvements in their key activities or processes to cope with the market fluctuations and increasing customer demands. Applying lean management philosophy is one of the most important concepts that help businesses to complete. In this paper, the literature survey findings such as existing level of lean practices, types of lean tools employed, and perceived level of different encountered by the various manufacturing industries are discussed.

RESEARCH OBJECTİVE AND METHODOLOGY

The primary aim of this study is to find out the needs and examine the degree to which the concepts of lean management are put into practice within various manufacturing Industry.

- This is an overview for finding the current situation of lean management practices in manufacturing industries.

- It is a measure to identify the constrains that retains lean manufacturing in the infant stage in manufacturing firms and helps to identify the muda (waste) that evolves in an processing unit and gives out supporting measures to remove the same. The constraint that predict the implementation and sustainability of lean manufacturing tools and techniques are also discussed.

LITERATURE REVIEW

A detailed review of research in current trend of lean management in garment industry has been discussed. Lean manufacturing is a multi-dimensional management practice including just in time-quality systems, work teams, cellular manufacturing, supplier management etc. the popular definition of Lean Manufacturing and the Toyota Production System usually consists of the following, Wilson (2009).

- It is a comprehensive set of techniques which when combined allows you to reduce and eliminate the wastes. This will make the company leaner, more flexible and responsive by reducing waste.

- Lean is the systematic approach to identifying and eliminating waste through continuous improvement by flowing the product or service at the pull of your customer in pursuit of perfection.

LEAN PRINCIPLE

Principle 1: Accurately specify value from customer perspective for both product and services.

Principle 2: Identify the value stream for products and services and remove non-value-adding waste along the value stream.

Principle 3: Make the product and services flow without interruption across the value stream. Principle 4: Authorize production of products and services based on the pull by the customer.

Principle 5: Strive for perfection by constantly removing layers of waste.

III. KIND OF WASTE

A. Overproduction

Producing items more than required at given point of time i.e. producing items without actual orders creating the excess of inventories which needs excess staffs, storage area as well as transportation etc.

B. Waiting

Workers waiting for raw material, the machine or information etc. is known as waiting and is the waste of productive time. The waiting can occur in various ways for example; due to unmatched worker/machine performance machine breakdowns, lack of work knowledge, stock outs etc.

C. Unnecessary Transport

Carrying of work in process (WIP) a long distance, insufficient transport, moving material from one place to another place is known as the unnecessary transport.

D. Over processing

Working on a product more than the actual requirements is termed as over processing. The over processing may be due to improper tools or improper procedures etc. The over processing is the waste of time and machines which does not add any value to the final product.

E. Excess Raw Material

This includes excess raw material, WIP, or finished goods causing longer lead times, obsolescence, damaged goods transportation and storage costs, and delay. Also, the extra inventory hides problems such as production imbalances late deliveries from suppliers, defects, equipment downtime, and long setup times.

F. Unnecessary Movement

Any wasted motion that the workers have to perform during their work is termed as unnecessary movement. For example, the movement during searching for tools, shifting WIP etc.

G.Defects

Defects in the processed parts are termed as waste. Repairing defective parts or producing defective parts or replacing the parts due to poor quality etc.is the waste of time and effort.

H. Unused Employee Creativity

Loosing of getting better ideas, improvement, skills and learning opportunities by avoiding the presence of employee is termed as unused employee creativity.

VI. LEAN MANUFACTURING TOOL

A. Continuous improvement

Continuous improvement (CI) can be defined as the planned, organized and systematic process of ongoing, incremental and company-wide change of existing practices aimed at improving company performance. Activities and behaviors that facilitate and enable the development of CI include problem solving, plan-do-check-act (PDCA) and other CI tools, policy deployment, cross-functional teams, a formal CI planning and management group, and formal systems for evaluating CI activities. Successful CI implementation involves not only the n-training and development of employees in the use of tools and processes, but also the establishment of a learning environment conducive to future continuous learning

The short description of PDCA cycle is given below

1) Plan: Identify an opportunity and plan for change.

2) Do: Implement the change on a small scale

3) Check: Use data to analyze the results of the change and determine whether it has made a difference.

4) Act: If the change was successful, implement it on a wide scale and continuously assess the results. If the change did not work, begin the cycle again.

Thus continuous improvement is an ongoing and never ending process; it measures only the achievements gained from the application of one process over the existing. So while selecting the continuous improvement plan one should concentrate on the area which needs more attention and which adds more value to our products.

B. Just-In-Time

Just in time is an integrated set of activities designed to achieve high volume production using the minimal inventories of raw materials, work in process and finished goods. Just in time is also based on the logic that nothing will be produced until it is needed.

Just-in-time manufacturing is a Japanese management philosophy applied in manufacturing. It involves having the right items with the right quality and quantity in the right place at the right time. The ability to manage inventory (which often accounts for as much as 80 percent of product cost) to coincide with market demand or changing product specifications can substantially boost profits and improve a manufacturer’s competitive position by reducing inventories and waste. In general, Just in Time (JIT) helps to optimize company resources like capital, equipment, and labor. The goal of JIT is the total elimination of waste in the manufacturing process.

C. Total Productive Maintenance

Machine breakdown is one of the major problems to production division. The reliability of the equipment on the shop floor is very important because if any one of the machines is down the entire shop floor productivity may be nil. The tool that takes care of these sudden breakdowns and awakes maintenance as well as production workers to minimize these unplanned breakdowns is called total productive maintenance. Total Productive Maintenance (TPM) is a maintenance program, which involves a newly defined concept for maintaining plants and equipment. The goal of the TPM program is to increase production, increase employee morale and job satisfaction.

TPM is set of tools, which when implemented in an organisation as a whole gives the best utilisation of machines with least disruption of production.

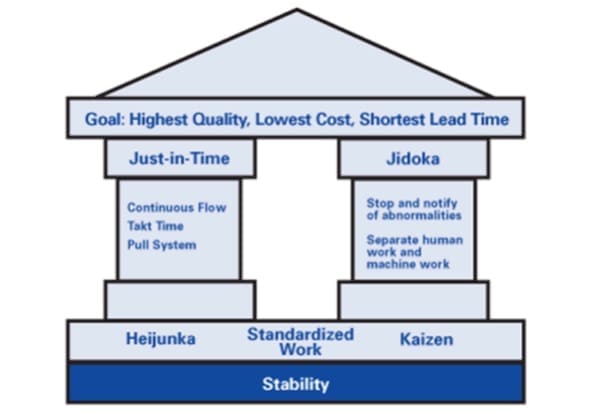

Lean production

Lean Production (LP) is a model of organisation focused on the customer and delivery of on time quality products, materials and information without any wastes, i.e., activities that add no value to the products from the point of view of customer. This designation, Lean Production means “doing more with less” where less implies less space occupied, less transports, less inventories, and most important, less human effort and less natural resources. LP had its roots in Toyota company that designed, after the Second Great War, a production system, Toyota Production System (TPS, which employed some pillars, like JIT production and automation concepts and some tools to reduce lead times and the cost of products.

It was a book named – “The Machine That Changed the World”- written by James P. Womack, Daniel T. Jones and Daniel Roos that gave the popularity to the Toyota Production System (TPS).

Meanwhile, the LP has evolved into a philosophy of thinking, Lean Thinking whose basic principles are

- Value

- Value Stream

- Continuous flow

- Pull System

- Pursuit perfection

These principles imply the dedication of all people, being the last one – pursuit perfection (principle 5) – the one that implies the strongest and continuously commitment of people in order to improve all the processes and activities in companies, through the waste elimination.

Lean Production and sustainable development

To satisfy the clients, companies consume energy, water and raw materials (natural resources) must be careful used. So, it is necessary to optimize the processes and prevent wastes of resources in a reasonable “doing more with less”. The relationship between Lean production and sustainable development is evident, sharing the same key idea of “creating or doing more with less”, and some organisations are benefiting from this relationship since, almost, two decades ago. Reviews had been made about this relationship and created a cause-effect diagram showing the evidence between the seven discussed wastes and the impact (effect) on the environmental performance. Lean Production carries a dramatic reduction to all kinds of wastes being a whole-system thinking and it is totally akin with a socially responsible strategy.

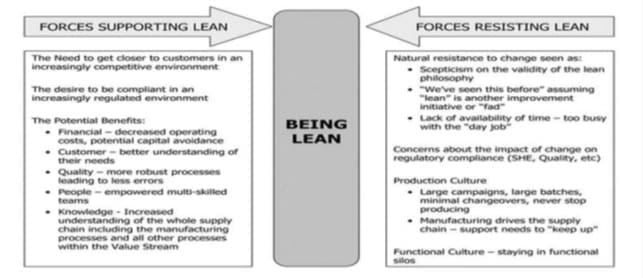

- CHALLENGES IN LEAN IMPLEMENTATION AND SUSTAINABILITY

The challenges faced in the process of implementing and sustain lean is a tedious job as the concept relates to time, cost, interest, and involvement, the concepts that together support the new change for development in an firm. The study tells that new firms introduce and accept lean manufacturing and other innovative concepts than the old and existing firms. The forces opposing and driving a change to lean is shown in image.The following important factor of resistance to change in manufacturing sectors is

- Fear to change the legacy system with the new successful trends and methodologies

- Not utilizing the opportunities and advantages of the new policies

- Market destabilisation will lead to force the change, which will be in a non-standard format.

Achieving sustainable work environment with Lean production

From the previous section, it was obvious that companies could save large amount in reducing wastes, particularly of SME companies. With some exceptions, garment companies are included in this category and presented many problems such as accumulated stocks everywhere due to the wrong product produced, to the anticipated production or to the large lots (overproduction), demotivation of operators and high absenteeism, high level of accidents, operator’s specialisation, high energy and water consumption, high raw materials consumption and disposal, high pollution of rivers, soil and air, among others.

According to the research, the apparel (garment) industry uses high volumes of water in raw material production however authors are more concerned in the manufacturing phase. This section mainly divulgate proposals to reduce the water and energy consumption, environmental wastes and raw materials in manufacturing phase. Additionally, proposals to improve leanness and agility are summarized.

Proposals for the reduction of energy and water consumption

This problem analysis could be detailed by technological process of the textile industry: spinning, weaving, textile ennoblement (dyeing and finishing), knitting and sewing. From all the processes, dyeing and finishing, are the one that consume more energy and water: it is impossible to dye and finishing without water and some processes have several washes, so, high water consumption and energy to heat the water.

Conclusion

Finally, this research shows the application of lean principles to the garment industry. According to our familiarity, it is the prime time that lean thinking has successfully implemented in the garment industry. We hope that this paper contains its worth for practitioners in the garment industries.

Due to increased customer expectations and severe global competition, the Indian garment industries try to increase productivity at lower cost and to produce with best product and service quality. Under these considerations, we have tried to implement lean manufacturing techniques and achieve improvement in process environment, drastic reduction in human fatigue and cost with reasonable investment.

References

- Mercado G. 2007. Question Garments- Ask the LeanManufacturing Experts Applying Lean in the GarmentIndustry Retrieved January 12, 2008, Thomas Publishing Company.

- Eswaramoorthi, G.R. Kathiresan, P.S.S.Prasad, P.V.Mohanram. A survey on lean practices inIndian machine tool industries. International journal of advanced manufacturing technology.2011, 52: 1091-1101.

- M. and Shook. J. 1999. Learning to see valueStream Mapping to added value and eliminate muda. International Journal of Physical Distribution and Logistics Management.

- FarhanaFerdousi and Amir Ahmed. 2009. AnInvestigation of Manufacturing Performance Improvement through Lean Production: A Study onBangladeshi Garment Firms, international journal ofbusiness management.

- S.J. 2003. Classification scheme for leanmanufacturing tools. Production and inventory management journal

- Brewer, A.S. and Pojasek, R.B. (2012). Assessing environmental sustainability performance at the national level environmental quality management

- Willem Niepce and Eric Molleman(1996) “A case study: Characteristics of work organisation in lean production and sociotechnical systems”,

International Journal of Operations & Production Management

- Gadekar, R.A. and Gadekar, A. (2015). Integration of lean-green manufacturing practices to towards environment friendly products: plastic industry. International Journal of Modern Trends in Engineering and Research.