- With the integration of its technologies, it promotes zero-discharge production that reduces time and costs, and increases productivity to guarantee the lowest cost per garment.

- Jeanologia is committed to the Pakistani textile industry and has been promoting hyper-automation and the environmental impact reduction of its washing processes, as well as training its professionals, for nearly 20 years.

Lahore, Pakistan.Jeanologia, a leading Spanish company in the development of eco-efficient technologies, is promoting Pakistan’s textile transformation at Igatex with more efficient and competitive sustainable production models. From December 1st to the 4th, it will display the keys to the future of Pakistan’s textile manufacturing industry, based on sustainability, digitalization and automation, at the Lahore Expo Center (Hall 3-stand 130)

For Jeanologia, Pakistan is one of the world hubs for denim production and its strength is fundamentally based on verticalization, from the initial fabric to the final garment. However, according to Najam Abedi, Area Manager at Jeanologia in Pakistan, the industry needs to invest in the hyper-automation of its washing processes, as well as in sustainability and in talent to strengthen its leadership as one of the world’s largest jeans producers.

“The textile industry has made great strides in recent years in the search for a more sustainable future. But it is necessary to accelerate the transformation of the denim industry by focusing on agility, customer centricity, speed, productivity and eco-efficiency, involving the market in this quantum leap” – pointed out Najam Abedi.

As part of its commitment to the development and transformation of the Pakistani textile industry, Jeanologia has been present in Pakistan for nearly 20 years, promoting hyper-automation and reducing the environmental impact of its washing processes, as well as training its professionals to increase their industry know-how through collaborative efforts with Pakistani partners and clients that improve textile production.

With the integration of its laser, G2 ozone, e-flow, Smart Box, and Colorbox technologies as well as H2Zero – the first water recycling system to achieve 100% ecological production – the company furthers zero-discharge textile production in Pakistan. This is a production model that reduces costs, shortens time-to-market to respond to market needs, and at the same time increases productivity to guarantee the lowest possible cost per garment.

With the integration of its laser, G2 ozone, e-flow, Smart Box, and Colorbox technologies as well as H2Zero – the first water recycling system to achieve 100% ecological production – the company furthers zero-discharge textile production in Pakistan. This is a production model that reduces costs, shortens time-to-market to respond to market needs, and at the same time increases productivity to guarantee the lowest possible cost per garment.

Thanks to the complete integration of Jeanologia technologies, a thorough transformation of the Pakistani textile industry is possible within Jeanologia’s commitment to achieve MissionZero: the elimination of 100% of the discharge generated in the manufacture and finishing of Blue Jeans. “We joined forces with the Pakistani textile industry to turn denim into the most sustainable garment on the market and a success story for other textiles” – emphasized Jeanolgia’s Pakistan Area Manager.

New operational models

With the perfect combination of Jeanologia’s hardware and software, the company continues to promote new operational models in the textile industry focused on digital production without contamination, streamlining processes and reducing costs, through eco-efficiency, creativity, digitalization and automation.

These production models provide five fundamental benefits for the textile industry: eco-efficiency, cost-neutrality, scalability, agility, and digitalization.

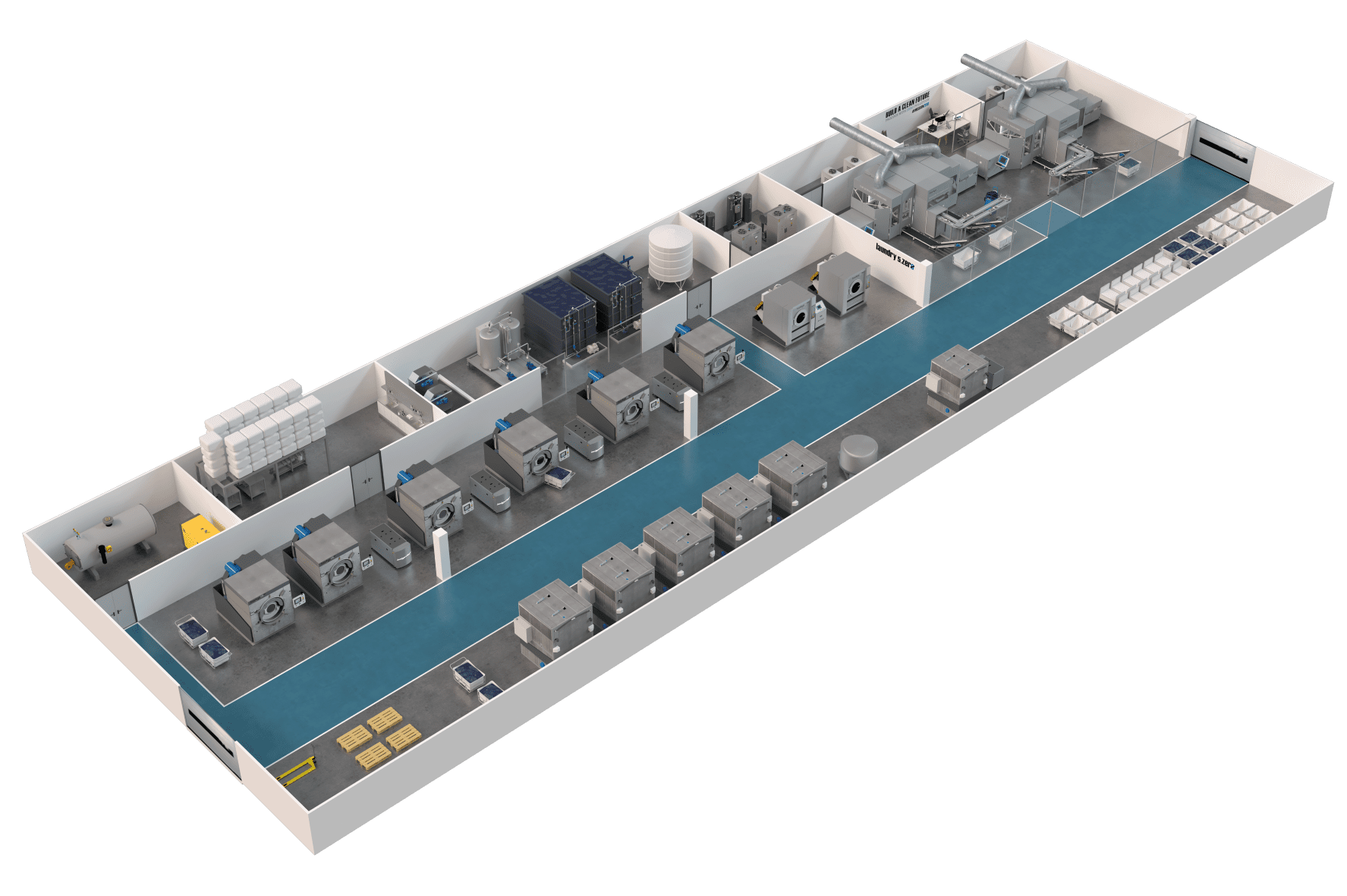

“Thanks to digitalization and automation, it is possible to make sustainable production scalable. We are committed to our technologies, and to LAUNDRY 5. ZERO – the garment finishing plant that guarantees ZERØ contamination – as well as the complete automation of washing processes, from laser technology to super-automatic washers. Furthermore, we’re dedicated to reducing the environmental impact of jean washing processes in order to continue positioning Pakistan’s textile industry as one of the world’s most competitive with a totally sustainable product”. – Najam Abedi summed up.

Pakistan was a pioneer in implementing the integration of Jeanologia technologies. In fact, the first Laundry 5.Zero facility was set up in Pakistan 4 years ago, enabling efficient and environmentally friendly production.