REVIEW ON FANCY AND NOVELTY YARNS IN DESIGNING SHIRTING FABRICS

Abstract

The fancy and novelty yarns are very decorative and special yarns which are used to ornament the fabrics like men’s shirting, jacketing, ladies wear to improve the aesthetic value fabric and get more attractiveness to product. This review article contains the introduction of fancy yarns which are used in shirting fabrics and their end use which are described with CAD images from time to time. The fancy yarns are intensively being used to decorate and to make fabric texture more creative than normal fabric. The end uses in term of CAD of fabrics are presented so as to understand how final fabric product will look like.

Introduction

The fancy yarns are those in which some deliberate decorative discontinuity of interruption is introduced. Of either colour or form or else both colour and form this continuity is introduced with intension for producing aesthetic effect.1 The word deliberate is very important here because all yarns made from staple fibres are inherently variable due to the imperfection of the yarn spinning systems and the no uniformity of fibre material. These yarns provide the fabric designer greater scope in achieving a more attractive and exclusive product, but also pose greater challenges as they usually suffer from poorer performance and higher costs. The fancy yarn gives a fancy touch to the fabrics to a broad range of end uses. Significant demand for the fancy yams is the ladies and children outerwear.1

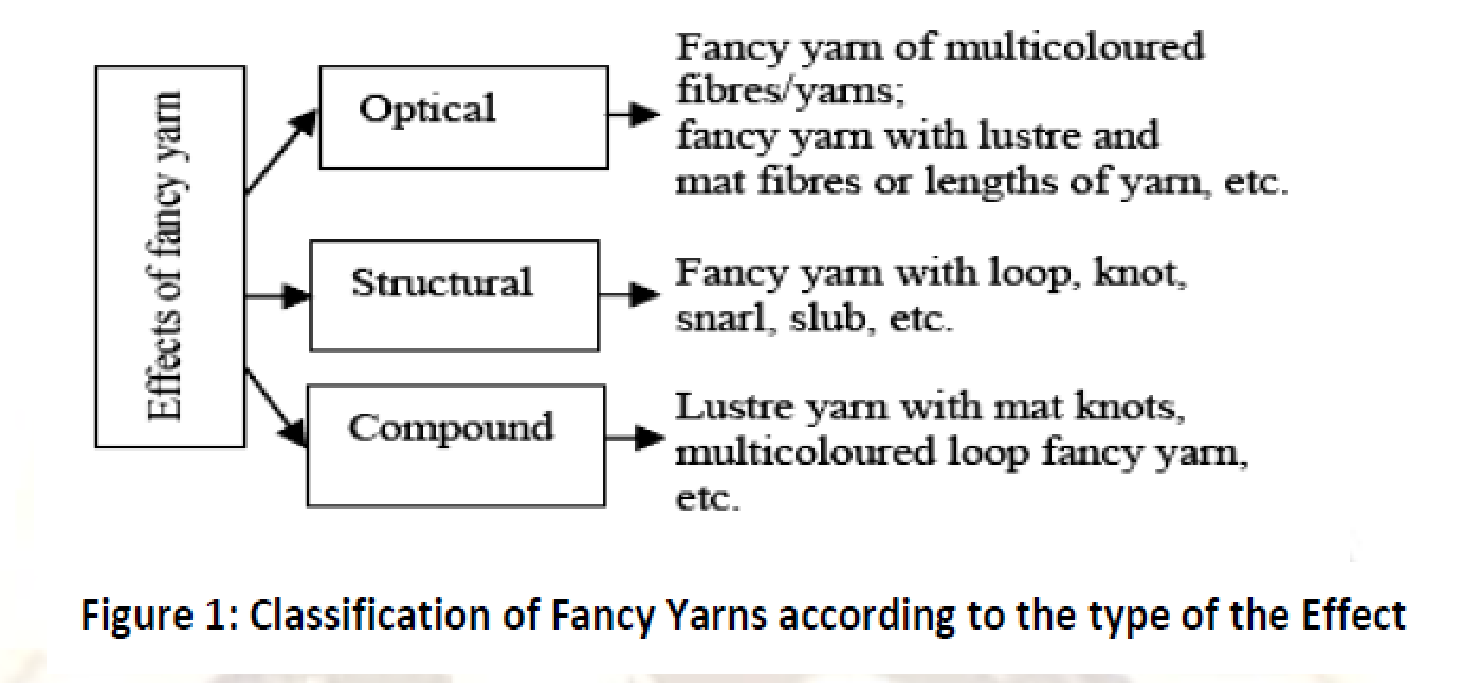

Classification of Fancy yarns

It would be a futile attempt to try to describe all the varieties of fancy yarns, as these are designed to differ by definition. From the point of how the variation is introduced in the yarn, fancy yarn effects may be broadly divided into two categories:

- Fibre effect and

- Yarn effect.

Fibre effects are introduced prior to the formation of yarn; yarn effects are introduced by combining two or more yarns after the individual yarns have already been made. The two categories can obviously be combined to make more complex effects.1

- Fibre effect

Fibre effect fancy yarns are created during the spinning processes prior to the formation of the final yarn. These yarns are characterized by varying sizes of fibre lumps along the yarn length. Depending on the size of these fibre lumps, these fibre effects are often further divided into three subcategories: nep, slub, and flake.1

- Yarn effect

Classification of fancy yarns is done according to the type and form of material used for effect making. Type of material used for effect making refers basic material of the components, viz; cotton, wool, silk, polyester, nylon, blend etc. Whereas form of material refers forms of components used for the intended purpose.2

Nep yarn

Nep or nupp yarn, has a compact yarn structure with specks of fibre clusters distributed along the base yarn structure. Figure-1 shows an example. These yarns are most effective when the effect fibres have contrasting colours to the base yarn fibre, whereas more subtle effects can be created when the effect fibre and the base yarn have similar colours. The distribution of the effects should generally be random to avoid the moire effect as shown in Figure 2.

Figure. 2. Nep yarns

The production of nepp yarns are usually achieved during the preparation of fibers. The most widely used method is mixing prepared fiber balls such as wool nepps into the main fiber stock before carding. The fiber effect can be varied by the mixing ratio and the card setting, in addition to the usual yarn parameters of linear density and twist.3

Multi-coloured Nep Yarn

In contest of Nep Yarns; the multi coloured nep yarns are produced with spinning multi-coloured fibres added into base yarns at specific interval of length. This will produce multi coloured effect on the yarn structure results into multi-coloured fabric structure on surface.1

Effect of nep yarn on fabric structure

In shirting fabric manufacturing, these nep / multicolour yarns are used to weave the fabric and decorative/fancy effect observed on fabric surface with yarn structure. While using these yarn some special care needs to take while wet processing due to use of peroxide bleaching and caustic etc. These may bleed colour in process if weaker dye affinity of mixed coloured fibres in yarn.

Below in Figure 3. are some fabric surface structure effects with Nep yarns:

Figure 3. Nep effect fabrics

Nep effect on cross-dyed fabric surface

Marl Yarn/ Grindle Yarn:

The simplest of the fancy effects, a marl yarn is one in which two yarns of the same count and twist, but of different colours, are folded together to form a balanced yarn as in Figure 4. They are, therefore, essentially plain folded yarns with the additional characteristic that the yarns folded together are of a different colour or texture. As such, they barely count as ‘fancy yarns’ at all, except in that they result in a subtle, but noticeable, modification to the appearance of the finished fabric. These yarns are used to good effect in discreet pinstripes for men’s suiting’s or to produce a subtly and irregularly patterned knitted fabric using a relatively simple fabric construction.1

Figure 4. Marl Yarn

Marl yarns are probably the simplest plied yarn structures. These are effectively straight folded yarns made by plying two, and sometimes more, yarns together. The individual component yarns are usually exactly the same in linear density and twist but often differ in colour or texture or both. The folding of these yarns creates a final yarn with subtle colour or texture variation. A typical use of marl yarns is men’s suiting fabric to create a pinstripe effect. Figure 5. shows an example of a marl yarn with three component yarns. If any of the component yarns differ in linear density or twist, yarn structure variation will occur and the final yarn will be unbalanced, although it may be a designed outcome.1

Figure 5. Grindle Yarn

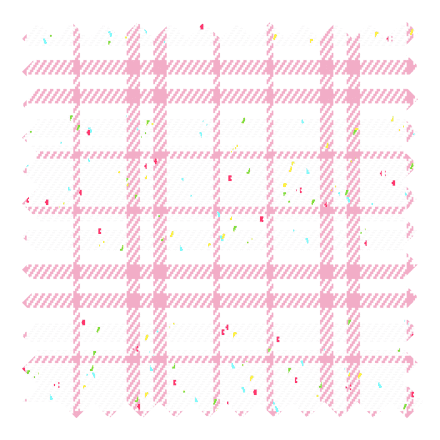

Effect of Marl Yarn on fabric Structure

Below are the some of CAD which shows the fabric structure with use of Marl yarn in yarn dyed shirting. Generally, these types of fabric are mostly used on suiting, jacketing, trim fabric and sometimes backed fabrics in garment industries. Figure 6. shows some of the effects on fabric.

Figure 6. Effect of Marl yarn on fabric structure

Space dyed yarns

Space dyeing involves dyeing of yarn with multiple colours to create abstract colour patterns which may or may not repeat after fixed intervals. Such space dyed yarns produce beautiful effects after weaving and knitting. They are used to produce fancy design effect when incorporated into apparel wear in shirting fabrics. Also these can impart effect of random, unorganised designs.

Space dyed yarn can be dyed either coordinating or contrasting shades. The coordinating colours are tones of neutral or assorted shades of hues like blue, green, red which provide subtle yet sophisticated look. While the effect of contrasting shades in space dyed yarn include mixing of purple, red, green and blue. Thus space dyeing is technique used to create lovely fabrics which shade from one colour to another.4

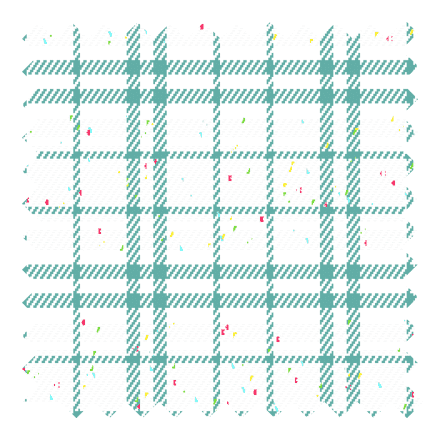

Effect of Space dyed yarn on fabric structure

Below CADs are shown of some Spacedyed structured appearance on fabric surfaces.in shirting designing most of fabric designed with Spacedyed yarns weaving in warp and weft directions. this creating random effects of Spacedyed in fabric.

Figure.7. Effect of Space dyes yarn on fabric structure

Melange Yarns

Melange yarn is a blend of different coloured fibres to develop various shades in the yarn. Difference in the ratio of fibres in the blend alters the uniqueness of spun melange yarn. Mélange yarn may be defined as “the yarn produced by the combination of at least two or more than two fibers”.

Conventionally, the term mélange is used for such yarns which are produced by the combination of two fibers (whether of same type but different in color or type of fiber used is different). In case of cotton mélange yarn “a mélange yarn is the yarn which is produced with various combinations of raw white and dyed cottons or dyed fibers.” For example, if we mix 99% raw white cotton and 1% dyed cotton (of any Colour), then it will have called Mélange yarn.5

Mélange yarn can be classified into two of its vary basic types:

i) Blended mélange yarn

ii) Non‐blended mélange yarn

- Blended Mélange yarn

Such type of yarn in which different fibers are mixed/blended together in a certain fixed ratio for instance PC (Polyester:Cotton blend) 50:50, PV (Polyester:Viscose) 80:20, CV (Cotton:Viscose) 60:40 etc.5

- Non‐blended Mélange yarn

Yarn in which there are no different fibers blended together, but different colored fibers of same type are used to make the yarn e.g. 100% cotton dyed yarn, etc.5

Figure 8. Mélange yarn packages

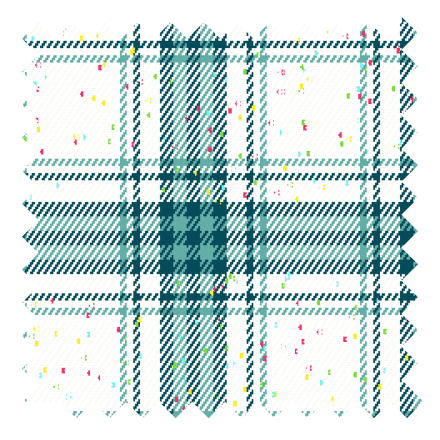

Effect of melange Yarn on fabric Structure

Mélange yarn can present multiple colors on one single yarn, which gives it rich colors, slenderness and tenderness. Textiles made of mélange yarns have a certain ambiguous cyclical effect. Figure 9. below shows some mélange effect on CAD.

Figure 9. Mélange effect on CAD

Slub yarns

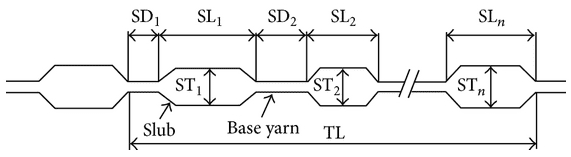

A slub yarn is one in which slubs have been deliberately created to produce the desired discontinuity of effect. Slubs are thick places in the yarn. They can take the form of a very gradual change, with only a slight thickening of the yarn at its thickest point. Alternatively, the slub may be three or four times the thickness of the base yarn, and that thickness may be achieved within a very short length of yarn. Since the structure is simply one of a gradually thickening and then tapering cylinder, a diagram has not been produced. The yarn pictures should give a clear enough impression of the structure of the yarn itself.1

Slub yarn refers to yarn that has been purposely spun with slubs (thicker sections along the yarn) while it was once seen only as a defect, slub yarn is now intentionally created to give fabric more effects.5

The visual effect of slub yarn

There are four factors are affect the visual effect of slub yarn:

- Number of slubs per kilometer (NSm)

- Diameter (dia) of slub

- Length of slub

- Distance between slub.

The Figure 10. below shows the parameters of slub yarns

Figure 10. Parameters of slub yarn

All these parameters are selected by computer. Slub vision software is used for this purpose. Figure 11. shows the effects with slub yarns.

Figure 11. Slub Yarns Effects

Types of slub yarn on the basis of visual effect:

- Pattern/regular slub yarn

- Non-pattern/irregular slub yarn

- Multicount slub yarn

- Both are pattern and non-pattern slub yarn.1

Figure 12 shows the effect of slub Yarn on fabric Structures.

Figure 12. Effects with Slub Yarns on fabrics

Conclusion

Now a days, Fancy yarn or novelty yarns are much more being used in apparel fabric to give them aesthetic and decorative structure to finished fabric. As per market trends these fabrics are much more used in shirting fabric to get attraction of customer and make the garments with creative and decorative effects.

As seen, Nep yarns are used in fabric to give nappy effect on solid base fabric structures, which enhance fabric appearance by its own nappy structure and give fabric colored look on surface and multi-colored nep nep yarns are showing very excellent texture on fabric structure and easily catching eyes of buyers.

Apart from this Mélange yarns and Slub yarns are produced while special spinning technique with mixing and draft adjustments which give the inherent yarn fancy effects and will show excellent appearance on finished fabric.

Marl yarns are twisted yarns, which used to decorate specific area in fabric or overall the fabric as per requirements. Space dyed techniques are dyeing technique which dyes yarn surface with multi colored intervals and this yarns will improve performance of finished fabric.

Still some research and developments are going on to produce more fancy yarns inherent and with dyeing techniques to make fabric more superior and cost effective. There is lot of scope in designing fancy yarns for end uses.

References

- V.R.H Gong and R. M. Wright, (2002). Fancy yarn: Their Manufacturing & Application, The Textile Institute, Cambridge, England: Woodhead publishing Ltd.

- Dr. Shaikh Tasnim Nisarahmed, Technology, Structure and Application of Fancy Yarns by International Journal of Engineering Research and Applications (IJERA) ISSN: 2248-9622, Vol. 2, Issue 3, May-Jun 2012, pp. 3109-3117.

- Different Type of Fancy Yarns & their Usage in www.textilecoarse.blogspot.com

- Ashok Athaly, (2014). Space dying available at www.fibre2fashion.com

- Basic Information: What is Slub yarn available at www.textilelearner.blogspot.com

Author:

SADDAMHUSEN JAMADAR

Executive-Design & Development (Export Division),

Raymond Luxury Cottons Limited