Ulaganathan, Director(EPQA) & Dr. K.R.K. Iyer, Consultant

Textiles Committee, Mumbai

Introduction:

One of the most spectacular events in the Indian textile scenario in the first decade of the current century has been the modernization of ginning industry which, for many years had remained in a decadent state. The Technology Mission on Cotton (TMC), a subsidy scheme launched by the Govt. of India in February, 2000 had a component referred to as Mini Mission IV for modernization of ginneries through which as many as 850 Ginning & Pressing (G&P) units were upgraded or newly set up till the scheme ended in December 2010. Although this number fell short of the target of 1000 ginneries set by the Textile Ministry, the effort made by the Cotton Corporation of India, the implementing agency for Mini Mission IV, has been hailed as a veritable success, judging by the quantum jump in cotton quality acknowledged by consuming spinning mills.

In the early years of TMC, the setting up of a new G&P unit was accepted as an economically viable proposition. Machinery costs were low, civil construction costs were moderate and labour was cheap and easily available. Electricity cost was also reasonable. A ginnery of average level of technology with a production capacity of 100 bales per day could be set up on an available land with an investment of Rs.150 lakh. With TMC’s capital subsidy of Rs.27 laklh, the nett investment was just Rs.123 lakh which could fetch a reasonable profit for a factory owner even if he did only job-work for cotton traders. The profit margin was predictably much more if the ginner chose to do trading in cotton by purchasing kapas, gining it in his own factory and selling the bales to spinning mills or to other traders.

Today, 12 years after the launch of TMC, many things have changed. Ginning machinery costs have escalated. So have civil construction costs. Wages too are far more than what they used to be ten years ago. Electricity bills are also higher. Despite a significant increase in processing charges for each bale received by the job-working ginner, he is unable to make a reasonable nett profit. Even with the subsidy of Rs.50 lakh offered under the NABARD Scheme, investment in a ginning unit solely for job work is not economically viable. This article is an attempt to work out the current cost burden the investor has to bear while setting up the G&P unit and the recurring expenditure he has to incur. It is shown that high-investment ginneries cannot survive through job work alone.

Economics of a Standard Ginnery (100 bales per day)

- a) Capital Investment:

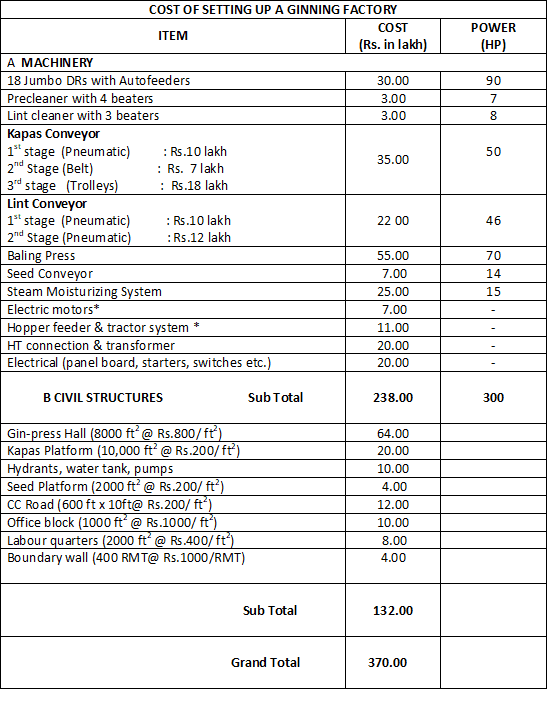

A ginnery with 18 Jumbo DRs which can produce lint equivalent to about 8 bales in an hour, accepted by TMC as a standard unit, is considered here for working out the economics. Pre-cleaner and lint cleaner should be of reasonable quality. A combination of pneumatic suction, belt conveyor and trolley system for kapas to be fed to each gin as well as fully pneumatic conveyor for lint from ginning machines to the on-line bale press are also presumed to be set up at the factory used in the analysis. The bale press would be an auto-loading, auto-tramping, 2-box machine. There would be on-line moisturizing facility through steam condensation system for lint and nozzle system for kapas. Seed conveyor and Weigh Bridge are also parts of essential components of a modern ginnery.

Civil structures will include, gin-press hall, open platforms for kapas, seed and pressed bales, bale go-down, fire fighting system comprising hydrants, water tanks and pumps, CC road etc,. which are normally considered as essential components of a G&P unit. In addition, a factory will also need office block, labour quarters and boundary wall for proper functioning of the establishment.

- b) Labour and Electricity Expenses:

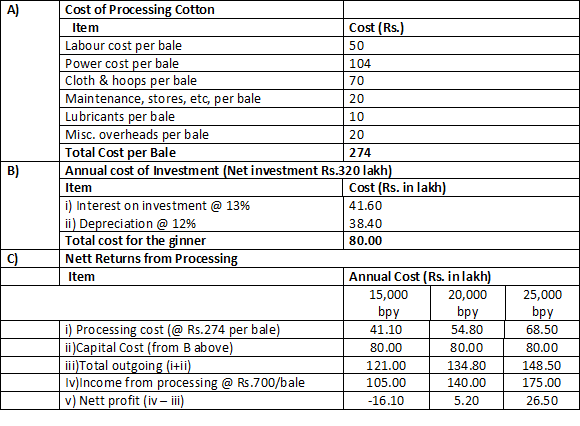

Since the factory considered here is one with automatic conveyor systems and on-line automatic baling press, the labour involvement is minimal. With just 21 labourers, including skilled and unskilled ones working during each shift for a wage of Rs.150/-, the labour cost per bale comes to Rs.50.

The total electric power of ginning machines (90 HP), conveyor systems (140 HP) and baling press (70 HP) in the unit is 300 HP. Electricity cost works out to Rs.104 per bale which has 3 components namely cost of ginning (Rs.38 per bale), cost of conveyance (Rs.55 per bale) and cost of pressing (Rs.11 per bale). A power cost at the rate of Rs.6 per unit (KWH) has been assumed for the calculations.

- c) Total Processing Cost per Bale:

Other expenses include bale covering cloth (Rs.35 per bale), plastic straps (Rs.35 per bale), machinery maintenance (Rs.20 per bale), lubricants (Rs.10 per bale) and miscellaneous overheads (Rs.20 per bale). With contribution from all these components, the processing expenses totals up to Rs.274 per bale which also includes labour and electricity costs against the job-work rate of Rs.700 per bale received by the ginner from traders or spinning mills for whom the ginnery undertakes ginning and pressing work.

- d) Annual Cost of Capital Investment:

Capital cost of investment in the ginnery involves machinery and civil structural components. For the factory considered for discussion, these are Rs.240 lakh and Rs.130 lakh respectively, totaling upto Rs.370 lakh of gross capital investment (Table 1). Let’s assume that the factory is entitled to receive a subsidy of Rs.50 lakh such as the one dispensed by NABARD. The nett investment would then come down to Rs.320 lakh. If interest on borrowings is taken as 13% and, assuming a depreciation of 12%, the annual recurring cost of the nett investment of Rs.320 lakh will work out to Rs.80 lakh.

- e) Returns from Job Work at the Ginnery:

If the factory is dedicated to job-work and is processing traders’ cotton, the factory owner would receive Rs.700 per bale, at today’s prevailing rates. The factory’s annual turn-over and net profit will depend on the number of bales processed in a season.

Three cases are considered here namely 15,000, 20,000 & 25,000 bales processed in the unit, in a season (October to April). The income at the rate of Rs.700 per bale is to be matched against the sum of processing cost (Rs.274 per bale) and the capital cost (Rs.80 lakh per annum). The nett profit has been shown in Table 2.

It is obvious from the data in Table 2. that the factory will earn a reasonable profit (Rs.26.50 lakh), only if it processes 25,000 bales. At 20,000 bales, it will just break even. If the bales are fewer, the factory will lose heavily. On the other hand, if over 25,000 bales are turned out, the profit margin can be quite attractive. But it is very unlikely that a factory could manage to get such large job-work contracts in a season.

Can Ginning be Made Remunerative?

In the wider national interest of providing quality cotton to textile mills, it is essential that ginning is viewed as a sector deserving support from the Government. Subsidies through fresh schemes on the lines of TMC with a threshold of Rs.50 lakh, tax holiday, exempting ginning machinery from Excise Duty liability etc. would make investment in ginning an economically meaningful proposition.

Alternatives Before the Ginner:

Discussions above tend to suggest that job-work would not bring significant returns from investment in a G&P unit. Two options are available for the factory owner:

- Be a cotton trader besides being a ginner.

- Restrict the size of investment by opting for a lower level of technology for the machinery.

To begin with, a factory owner could earmark 50% of the days for job-work while the remaining days could be used for ginning his own cotton. Of course, raising working capital, understanding the nitty-gritty of seed cotton purchase, and learning the nuances of marketing bales would be formidable challenges for a new entrant. For the second option of reducing the size of capital investment, the ginner will have to content with belt conveyors for lint as well as kapas, nozzle spray system instead of steam system for moisturizing lint, semi-automatic bale press, minimal size for civil structures etc.

How Traders and Trading Orgnizations Can Help:

Job work charges per bale should be linked to the technical features of the ginnery such as the quality of machines, degree of automation, and excellence of civil infrastructure. Differential job-work rates will be justified inasmuch as the level of modernization of the factory will directly impact on the quality of baled cotton. It will be equally appropriate for a good factory to demand higher processing rate. It will be also beneficial for the traders and trading organizations like CCI to pay more and get their cotton processed in a factory of superior level of modernization. Ginners’ associations and trade organizations should come together for an introspective discussion on this matter.

Star Rating of Ginneries:

A mention of Textiles Committee’s Star Rating Scheme for G&P units becomes relevant here. Ratings ranging from “Single Star” to “Five Star” assigned by Textiles Committee to modernized ginneries will reflect the technical excellence of the G&P factory and would serve as a measure of the quality of cotton bales that could emerge from the unit. The rating scheme is becoming popular among the ginners, spinners and the trading community.

Already about 400 units have been assigned star ratings. Many others are in the process of being assessed. By the end of this current season, over 500 units would have been rated. Both cotton traders and spinning mills stand to benefit a good deal by making use of the information on rated units available on Textiles Committee’s Website. The differential ginning-pressing rate for job work discussed in the last paragraph should be appropriately fixed in on the basis of the star rating accorded to each unit.

Summary & Conclusions:

- At current rates, the cost of processing a bale of cotton in a modernized ginnery works out to Rs.274/-.

- An investment of Rs.370 lakhs on a ginnery of a high level of technology even with a subsidy of Rs.50 lakh would translate into annual cost of Rs.80 lakh towards interest and depreciation.

- With current ginning charges set at Rs.700/- per bale, a job working ginnery will make no profit even with 20,000 bales processed in one season.

- Only if the ginnery processes 25,000 bales or more will it earn reasonable returns from the investment.

Generous Govt. subsidies on the lines of TMC, excise duty exemption for ginning machines, tax holidays, fixing ginning-pressing rates in relation to Star Rating status of G&P units, etc. are steps that will (a) enable a job-working ginnery to make profit and (b) provide impetus to sustained investment in the ginning sector.

Table 1: Capital Investment for an Automatic G&P Factory

* HP included in other items

Table 2: Economics of a Modern G& P Unit

bpy : Bales per year