Shishir Tyagi*,Dr. M. Choudhari and Mayur Basuk

Wool Research Association, Kolshet Road, Thane-400 607

* All correspondence should be addressed to Shishir Tyagi, email id: styagi@wraindia.com

Introduction to Warp-knitting machines

Warp knitting is one of the knitting methods which are also the fastest method of producing fabric from yarn. Warp knitting differs from weft knitting in that each needle loops has its own thread. The needles produce parallel rows of loops simultaneously that are interlocked in a zigzag pattern. Fabric is produced in sheet or flat form using one or more sets of warp yarn. The yarns are fed from warp beams to a row of needles extending across the width of the machine. The first warp-knitting machine was invented by Crane, an Englishman. It was a single guide bar machine to make blue and white zig-zag striped silk hosiery and these fabrics were named after Van Dyck, the painter.

Warp knitting is one of the knitting methods which are also the fastest method of producing fabric from yarn. Warp knitting differs from weft knitting in that each needle loops has its own thread. The needles produce parallel rows of loops simultaneously that are interlocked in a zigzag pattern. Fabric is produced in sheet or flat form using one or more sets of warp yarn. The yarns are fed from warp beams to a row of needles extending across the width of the machine. The first warp-knitting machine was invented by Crane, an Englishman. It was a single guide bar machine to make blue and white zig-zag striped silk hosiery and these fabrics were named after Van Dyck, the painter.

Types of Warp Knitting:

1) Tricot Knit: Tricot fabric is soft, wrinkle resistant & has good drapability. Tricot knits are used for a wide verity of fabric weights & design. It makes light fabric weighting less than 4 ounce/square yard. Some examples of tricot fabric are sleepwear, boluses, dresses etc.

2) Raschel Knit: The Raschel knit ranks in importance of production with tricot but it makes varieties of products ranging from sports nets, spacer fabrics, mesh fabrics etc. Raschel knitting is done with heavy yarns & usually has a complex lace-like pattern

3) Crochet Knit: This basic stitch is used in hand crochet. This construction is used in a wide variety of fabrics ranging from nets & laces to bed spreads & carpets, various types of edgings or trimmings lace are also produced.

4) Milanese Knit: The Milanese stitch produces a fabric very similar to tricot. It can be identified by the fine rib on the face & a diagonal pattern on the back. However, Milanese fabric is superior to tricot in smoothness, elasticity, regularity of structure & friction resistance.

Though, there are four type of warp knitting but the prominent warp knitting used is Tricot and Raschel warp knitting which are made on Tricot warp knitting machine and Raschel warp knitting machine respectively. The principal differences between tricot and Raschel machines are listed here:

- Latch needles are generally used in Raschel machines, while bearded or compound needle machines are referred to as tricot machines. Compound needle Raschel machines are also now fairly common. The compound needle is the most commonly used needle on warp knitting equipment.

- In Raschel machines the fabric is taken up parallel to the needle stems; in the tricot machines, however, it is taken up at approximately right angles to the needles.

- Raschel machines are normally in a coarser gauge; they are also slower compared with tricot machines, because more guide bars are frequently used and they also require a longer and slower needle movement.

- Raschel machines are much more versatile in terms of their ability to knit most types of yarns such as staple yarns, and split films, etc. Only continuous-filament yarns can be successfully knitted on most tricot machines.

Specification of Raschel warp knitting machine installed at WRA’s COE-Sportech

Technical specification

- Working width: 1270 mm

- 12 guide bars with electronic control

- 2 sinker bars

- Needle type: latch

- Needle bed type: double needle bed

- Gauges: 5 – 10 – 15 n.p.i.(needles per inch)

- Stitch density (on both needle beds): 1 – 40 stitches/cm

- Distance between needle beds: 1 – 16 mm

- Products: Sports nets, Spacer fabrics, Bandages, Mesh structures fabrics etc.

- Technical uses (netting for sports equipment and the food industry, high resistance ribbons in special fibres, ribbons and fabrics for applications in the geo-textile, automotive, building and industrial sectors)

- Medical uses (tubular elastic netting, emergency bandages and dressings, disposable underwear)

- Footwear (spacer fabrics for uppers)

- Women’s Apparel (mesh stockings and pantyhose) and fashion fabrics.

Electronic double needle bed warp knitting machine for the production of a wide range of articles, such as, for example for:

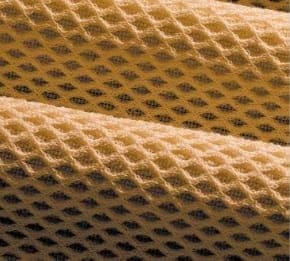

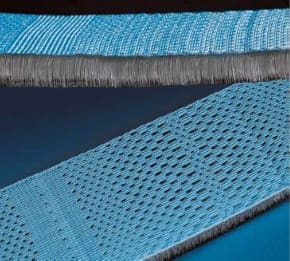

A- Spacer Fabric B- Spacer Fabric

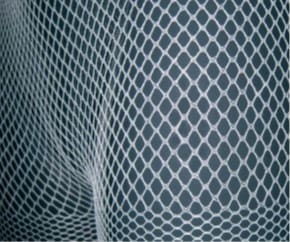

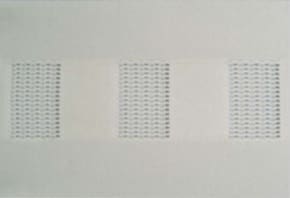

C – Sports nets D- Mesh structures fabrics

E – Bandages

Reference:

- https://textilelearner.blogspot.in/2011/06/warp-knitting-types-of-warp-knitting_6298.html

- knitting technology by David J Spencer

- https://en.wikipedia.org/wiki/Warp_knitting

- https://www.comez.com/index.php/en/2013-04-23-16-04-21/2013-04-23-16-05-46/dnb-1270