Innovative Apparel Products Development from Khadi Fabric

A.N.Sai Krishnan* and V.Chandrasekaran

E-mail: [email protected]

Department of Apparel Technology, PSG Polytechnic College, Coimbatore 641 004, India

Abstract

Innovations in apparel and fashion product play a vital role in fulfilling the expectation of the customers. Presently innovations in apparel and fashion products are happening in many ways such as changes of styles, value addition by using with new textile materials and finishes. In this work we have developed an innovative apparel products by using khadi cotton fabric. Since khadi is having a rich tradition and unique texture due to hand spun yarn. The value added apparel product were developed by analyzing the existing styles of men’s ,women’s and children’s wear and new styles is developed based on current trends. Value addition is given by hand painting, printing, and surface ornamentation techniques. Fusion kind of design is also developed by placing khadi fabric in selective panels in knitted garments. Comfort properties, fit analysis and wear study is investigated and reported. The results of comfort properties shows better from khadi fabric due to low fabric yield and inherent nature of hand spun cotton yarn . The results of subjective evaluation in comfort and fit analysis shows very good rating scale for all the styles. Our findings in market feasibility from customer and retailer perspective show good potential by developing innovation in khadi fabrics.

Keywords : Khadi ,casuals, Warli, Madhubani Printing and Embroidery

- Introduction Khadi or khaddar is the term conventionally used in North and Central India to refer the varieties of coarse cotton cloth hand woven using hand spun yarn. This was the cloth commonly worn by peasant and artisan groups in pre-industrial India. It was made from locally grown cotton which would be harvested by peasants and laborers, spun by local women and woven into cloth by men from various specialist weavers. The precise technology involved in the production of khadi would vary from region to region, as would the techniques used for its decoration (dyeing, embroidery, printing etc.) Although hand spun hand woven cotton cloth of this kind was common throughout India, khadi entered nationalist vocabulary and the cloth became a key visual symbol of india‘s struggle from colonial rule. Characteristics of khadi fabric are cool in summer and warm in winter due to soft feel and tactile property of the fabric. It is the only fabric where the texture is so unique that no two fabrics will be absolutely identical. Khadi is also an eco- friendly fabric as such the process involves no environmental pollution.. Since Innovation plays critical important in the apparel and fashion industry to fulfill the niche market. In this work we have made an attempt in developing innovative fashion products by using khadi fabric. The fit analysis and comfort related test for khadi fabric and apparels is investigated and reported

- Materials and Methodology

To verify the prevalence of innovation in khadi garments a survey has been carried out by visiting in leading apparel retail show rooms. The percentage of value addition given for khadi fabric found on the garment was only 34%.. in our study conducted . Totally we have developed 10 garments styles each garment we have chosen different traditional designs and motifs of warli, kasuti embroidery and kantha embroidery, application of this method is carried out by using screen printing, block printing, hand embroidery, machine embroidery and painting, the details of apparel styles developed were mentioned in the table 1.Important fabric test like longitudinal wicking, diffusion ,water absorption , air permeability and water vapour permeability were tested based on international standard testing procedure.

These garments were constructed by using single needle, over lock and flat lock sewing machine. By considering current trend and fit, the modification of pattern shape is carried in critical zones like chest, length, arm hole shapes. Garment fit is also analyzed by putting the garment in the standardized dress forms. The subjective evaluation is also carried out by taking the opinion from the wearer’s perspective. The rating scale is also developed by choosing the ranking (Ranking: 1- Poor, 2 – Average, 3-Good, 4-Very Good, 5-Excellent).The opinion is taken by considering aesthetic look of the garment, suitability for current fashion and fit .Garments are taken photo prints by displaying in the dress forms and mannequin’s.

Table 1 Garment Style details

|

Style code |

Garment style |

Target group |

| A | Mandarin collar top | Women’s wear |

| B | Slim fit shirt | Men’s wear |

| C | Over coat with ruffles | Children’s wear |

| D |

A-line frock with panels |

Children’s wear |

Table 1 Garment Style details

|

Style code |

Garment style |

Target group |

| A | Mandarin collar top | Women’s wear |

| B | Slim fit shirt | Men’s wear |

| C | Over coat with ruffles | Children’s wear |

| D |

A-line frock with panels |

Children’s wear |

| E |

Slim fit shirt with Mahatma Gandhi images – screen printing |

Men’s wear |

| F |

Slim fit with khadi mixed |

Men’s wear |

| G |

Polo collar t-shirt |

Men’s wear |

| H | Slim fit with Kasuti Embroidery | Women’s wear |

| I | Knife Pleated long top with Warli screen and hand block printing | Women’s wear |

| J | Kurtha with pleats with Kantha Embroidery | Women’s wear |

3..Results And Discussion

3..1 Fabric properties analysis

The khadi fabric were tested for various fabric properties the results were mentioned in the table 2. The comfort property test results shows that wetability time takes longer due to the presence of starch content in the fabric , however the water absorption, longitudinal wickability and diffusion is better. The longitudinal wicking height is increased gradually form 3min to 5 min time for all the different types of fabrics. The water vapour permeability results calculated for one day shows better for all the fabric and there is good correlation in wicking height and water vapour permeability rate.

Table 2.Cotton khadi Fabric Properties test result

| S.nO | Properties | Brown | White | Pink | Sandal |

| 1 | Fabric yield, g/m2 | 130 | 57 | 130 | 135 |

| 2 | Warp count, NE

|

20 | 60 | 20

|

20 |

| 3 | Weft count, NE

|

20 | 50 | 20 | 20 |

| 4 | EPI(ends per inch) | 48 | 86 | 48 | 54 |

|

5 |

PPI(picks per inch) | 46 | 78 | 42 |

48 |

| 6 | Thickness(mm)

|

0.37 | 0.19 | 0.31 | 0.44 |

| 7 | Water absorption(sinking time)sec | 19.46

|

11.6 | 15.14 | 18.32 |

| 8

|

Water absorbancy(wetability)sec | 31.46 | 11.2 | 22.76 | 24.32 |

|

9 |

Water absorbancy (static immersion)% | 92.14 | 233.33 | 86.32

|

89.49 |

|

10 |

Longitudinal wickability,cm |

3 min 5min

8.42 8.88 |

3 min 5 min

4.1 5.1 |

3 min 5 min

7.25 7.75 |

3 min 5 min

8.42 8.88 |

|

11

|

Diffusion,c m2 | 3.125 | 7.5 | 10.35 | 5.32

|

|

12

|

Water vapour permeability,g/m2 | 725.05 | 735.44 | 699.06 | 719.85 |

3.2 Khadi garment fit analysis

The khadi garment fit has been changed by reducing the measurement in critical measurement zones. Overall the measurements were reduced by 2cm , the yoke width is reduced by 1 cm. From the wearers perspective the ergonomic wear comfort is significantly improved by modifying the measurement.

Table 3 Fit Modification of Shirt

| S.NO | Description | Existing style

measurements |

Modified style measurements | Difference ,cm |

| 1 | Full length | 82

|

80 | -2 |

| 2

|

Chest |

55 |

52 | -2 |

| 3

|

Waist | 52 | 50 | -2 |

| 4

|

Pocket height | 12 | 12 | nil |

| 5

|

Pocket width | 12 | 12 | nil |

| 6 | Shoulder point to point | 48 | 49 | -1 |

| 7

|

Arm hole | 46 | 44 | -2 |

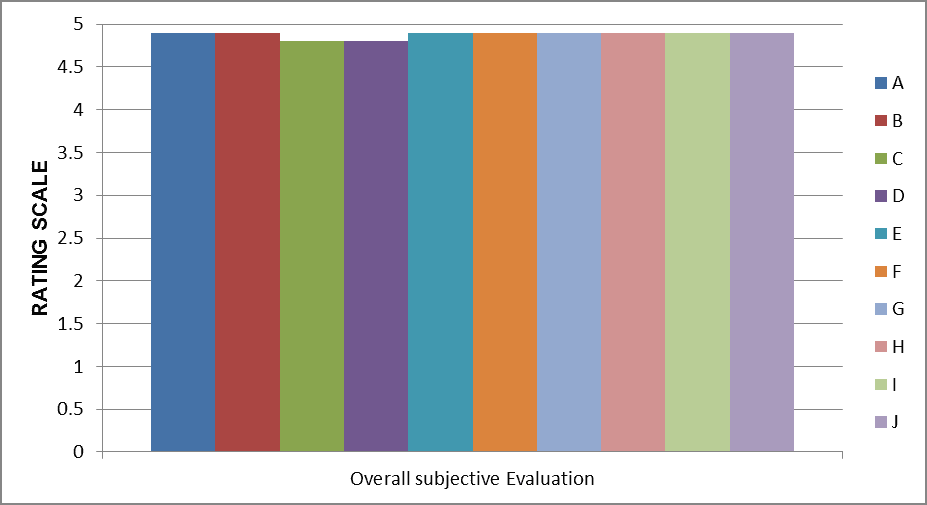

3.3 Overall subjective Evaluation rating

The overall subjective evaluation rating scale for all the 10 garments shows very good excellent rating scale from the customers perspective

Fig 5.3.11 Overall subjective Evaluation for 10 Garments

Conclusion

We have successfully completed our work by developing innovative apparel and fashion products by using khadi fabric. The conclusion of our work is summarized below.

- In our initial market survey carried out in the leading apparel show room, the value addition given to the khadi fabric is very less in our findings.

- The fabric results of khadi materials shows that drape coefficient is normal and flexural rigidly is higher due to presence of starch content; it could be reduced by special surface finish.

- Although the water absorption influence by fabric comfort The comfort properties like longitudinal and water vapor permeability shows good results due to presence of cotton material and the feel of fabric is gritty it could be improved by surface finishes.

- Fit of the khadi apparel is phenomenally improve by slight modification in critical measurement zones like chest , back width and armhole.

- Overall subjective rating scale for all the 10 garments developed shows Very good to Excellent rating scale from the wearer’s perspective.

- The opinion from retailers and customers perspective about khadi innovative apparel and fashion product we developed gives overwhelming positive feedback.

- The total cost of developing the design for the ten garments is Rs. 1500. The development cost of the design is affordable. The machine embroidery cost is little higher due to investment cost of the machine. When we produce in the mass production the rate could be reduced.

- There is a huge gap to be filled in value addition on khadi apparel, fulfilling the market space by developing innovative apparel and fashion product will bring benefit to all the stake holders in khadi allied industries .

Acknowledgement

The authors acknowledge the support given by the Management, the Principal and Head of the Department of Apparel Technology, PSG Polytechnic College for their encouragement and support in completion of this work. Also we thank our students of Apparel Technology S. Nivetha S.Sowmiya ,D.J.Sri Aishwarya,and S.Varatha Alwar who contributed for this work.

References

1.Marian L Davis, “Visual Design in Dress”, Third edition Prentice hall, 1996.

- Elaine Stone, “The Dynamics of fashion”, Fairchild publication, 2001.

- Jay Diamond and Ellen Diamond, “The Word of Fashion “,Second edition, Fairchild publication,1999.

4.www.Khadi And Village Industries

- Prakash,”Inspirational Textile Design”, Textra Design Book, January,1997, p.42

- Dr.Shailaja D.Naik,”Traditional Embroideries Of India”, A.P.H Publishing Corporation, 1996, pp 15-142

- Terry Brackenbury, “Knitted Clothing Technology”, Blackwell Science Ltd, 1992, pp 1-63

- Dr.Shailaja D.Naik and Jyothi V.Vastrad ,“ Protection and revival of traditional hand embroidery kasuti by automation”, Indian Journal of Traditional Knowledge, Vol 7(1), January 2008, pp197-203.

9 .Amita D Pandya and Kruthi L Dholakia “, Historical Overview of Kutch Embroideries”, Indian Journal of Traditional Knowledge, Vol 12(3), July 2013, pp 524-529.

- Namrata M and Shailaja D Naik”, Contemporized traditional textile made-ups- A mode for rural and urban linkage”, Indian Journal of Traditional Knowledge, Vol 7(1), January 2008, pp 208-211.

- Marian L Davis,”Visual Design in Dress”, Third edition Prentice Hall, 1996.

- Elaine Stone,” The Dynamics of fashion”, Fairchild publication, 2001.

- Jay Diamond and Ellen Diamond,” The World of Fashion”, Second edition, Fairchild publication, 1999.