Ms. Juhi Agarwal Dr. Ela Dedhia

University Department of Textile Science Department of Fashion Technology

and Apparel Designing College of Home Science,

SNDT Women’s University, Mumbai, India Nirmala Niketan, Mumbai, India

Abstract

Mesta is a bast fibre crop and a close substitute to jute in terms of its fibre characteristics and fibre appearance. It is obtained from the bark of Hibiscus Sabdariffa which belongs to family Malvaceae. Bureau of Indian Standards (BIS) has introduced a grading standard on the basis of scoring system for Mesta fibres like jute which is still followed religiously. Six grades have been prescribed for mesta. The fibre is graded on the basis of six physical parameters i.e., strength, root content, defects, fineness, colour and density. Scores for the mesta can be taken as guidance for determining the quality or grade of the fibre which will further justify the commercial value of the same. The Mesta fibre found in Andhra pradesh (AMV 2) is found to have better grade than the fibre found in Maharashtra (Race Ruber).

Introduction

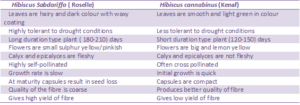

Mesta is a common word used for two species namely Hibiscus cannabinus and Hibiscus Sabdariffa which produces good fibre for commerce. It is considered as a substitute for jute and it is also referred to as a multipurpose crop since each and every part of mesta has some utility. The two major fibre yielding species of Hibiscus cannabinus and Hibiscus Sabdariffa have the following characteristics:

What is the Grading of Mesta Fibre and how it is done?

The quality of any fibre is usually judged by its suitability for the production of different types of yarn and its behavior in the manufacturing process. Same principle applies for mesta fibre too. The BIS grading of mesta envisages a score card system of grading that aims at eliminating personal bias as far as possible. Six physical parameters i.e., strength, root content, defects, fineness, colour and density of mesta fibres are assessed for sorting out the fibre into six different grades. Relative weightage is given to each physical parameter by standard scoring system and the grade of fibre is determined by total score of six parameters. (www.bis.org.in)

Grading Process

There are two systems for grading of mesta fibre:

- Hand and Eye method

An expert grader can assess the physical characteristics viz., fineness, density and strength of the fibre testing by hand only while visual assessment will judge colour, root content and defects by a close look at the fibre. Hand and eye method is generally used in the market for on the spot assessment of the quality and grading of fibres. This method is subjective and assessment may vary from person to person.

The six physical characters of fibre i.e., a) Strength, b) Fineness, c) Colour, d) Root content, e) Defects and f) Density are assessed by hand and eye method for grading following standard score card system of grading.

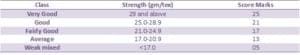

- A) Strength

For comparing strength of a fibre a bundle of 10-15 fibres from the middle region of the fibre reed is gripped between the thumb and forefinger of both the hands and broken longitudinally without jerk. It gives an idea of fibre strength. Good lustre of fibre is also an indicator of good fibre strength. Strength of mesta fibre is divided into five groups i.e., Very good, Good, Fairly good, Average and weak mixed. The scoring scheme for each group is shown in Table 1.

Table 1: Strength description and Score marks

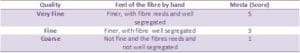

- B) Fineness

The fineness is a measure of diameter (width) or weight per unit length of fibre filament. Fineness is a genetic property which also depends on the age of the plant during harvesting ( Natural Fibres, 2009). Fineness can be estimated simply by having a close look at the fibre. Finer fibre shows better spinning quality. Fineness is divided into three groups i.e., Very fine, fine and coarse. The scoring scheme for each group is shown in Table 2

Table 2: Scoring Scheme for fineness

- C) Root Content

The hard barky region at the lower end of the reed is called root. The roots are cut at the mill before any processing of the fibre and in commerce they are known as “Cuttings”. Measuring the extent of the bark along the length of the reed by a scale and doubling the length percentage value of the root content may make an estimate of the root content in terms of weight percentage.

Table 3: Scoring Scheme for root content

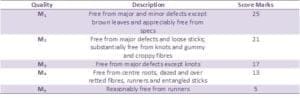

D) Colour

Colour is the property of the fibre that distinguishes its appearance as redness, yellowness, greyness etc. It is largely dependent on the retting conditions, water and washing. The terminology of different colours as defined in BIS specifcations with score marks for mesta are given in Table 4.

Table 4: Colour Description and score marks

Source: Bhaduri, S.K & Saha, S.C. (2008)

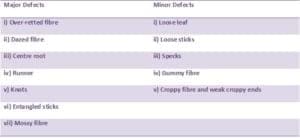

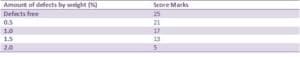

E) Defects

Factors causing serious or partial damage to the quality of the fibre are commonly known as defects. In all 12 defects have been identified in the body of the fibre, which are broadly classified into two groups, namely major defects and minor defects. All the major and minor defects are listed below:

Table 5: Defects of the Mesta fibre

Source: Bhaduri, S.K & Saha, S.C. (2008)

Table 6: Defects and Score Marks

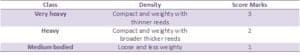

F) Density

Density is defined as weight per unit volume of fibre considering all air space in the fibre. It is judged by the feel of heaviness or lightness of a number of reeds from the middle region of bulk, held within a grip between two hands and raised up and down. The sample that feels compact and heavy with thinner reeds is graded as ‘very heavy’ and loose and less heavy one is ‘medium body’. Heavy bodied sample generally spin into good quality yarn.

Table 7: Scoring for Density

- Instrumental Method

In this method all the six physical characters of fibre essential for determining grade are measured by fibre testing instruments. The use of instruments is essential for an objective and accurate evaluation of grades. The instruments and their functionalities are mentioned below:

A) Fibre Bundle Strength Tester

The ability of the fibre to resist strain to the limit of rupture is called the strength of the fibre. The strength is measured as the breaking load of the fibre sample under test divided by the linear density of the unstrained fibre and is called its tenacity. This is expressed in gm/tex.

The test length of 5 cm is adopted as standard. Corresponding to this 5 cm test length the length of the fibre bundle is 12.5 cm and weight 200 to 400 mg is taken. The bundle strength of the fibre sample is its tenacity which is expressed in gm/tex.

Table 8: Scoring for the strength of the fibre

B) Airflow Fineness Tester

It is a measure of diameter or thickness of the fibre. Fineness is expressed by linear density or mass per unit length in tex(gm/km). The finer the fibre, the better is its quality. Airflow fineness tester is developed by NIRJAFT measures fineness of fibre on the principle of measuring specific surface of a constant mass of fibre. The instrument comprises of a device by which air is sucked through a sample of fibre plug at a constant pressure and the rate of flow is measured. The rate of flow is dependent on the fineness of fibres.

The working of the instrument is based on the measurement of rate of flow of air through a parallel fibre plug of specified mass (3gm) and length (5cm) placed in a cylindrical cell of fixed dimensions at a particular pressure difference between the ends of the plug. Under these conditions, the fibre fineness (tex) is proportional to the rate of flow of air. The airflow is maintained by a water aspirator system that can be repeatedly used without replacement. Two manometers placed, in an inclined position for greater sensitivity, measure the pressure difference and the airflow. The rate of airflow is calibrated in terms of ‘tex’.

Table 9: Scoring Scheme for fineness of the fibre

C) Colour and Lustre Meter

The colour and lustre meter is developed by NIRJAFT and is kind of reflectance photometer, which measures the brightness and lustre of the fibre sample in terms of diffused and specular reflectance using photoelectric cell. A beam of white light is made incident on the fibre sample over a specified area and the reflected beam of light from the flat surface of the sample is received by a photocell. The output current of the photocell is proportional to the amount of light received. Brightness or colour is measured by the ratio of diffused reflectance of a fibre sample and the reflectance of a standard white surface and is expressed in percent. Similarly, lustre is measured by the ratio of specular reflectance and diffused reflectance.

Table 10: Score for colour of the fibre

D) Bulk Density Meter

It determines the volume of a fixed mass of fibre including air space to indicate whether the fibre is very heavy, heavy or medium bodied, an aspect commonly used for quality assessment of mesta fibre.

Fibre bundle of fixed weight (40 gm) and length (10 cm) is held between the plates and compressed by a fixed load (10 kg) hanged from the bottom of the device. The bulk density is then calculated by dividing the mass by the volume under compression. The compression of the fibre sample as calibrated on a scale gives the measure of bulk density of the fibre expressed in gm/cc directly.

Table 11: Score for bulk density of the fibre

E) Defects

Defective portions are cut from a bundle of mesta fibre reeds and weighed. The weight expressed as percentage of total weight of the reed bundle give a measure of defects.

Table 12: Score for defects of the fibre

Source: Bhaduri, S.K & Saha, S.C. (2008)

F) Root Content

The instrumental method of measuring the root content is to simply cut the hard barky bottom region of the fibre reeds, obtain its weight and express it as percentage of the total weight of the reeds.

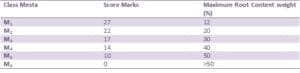

Table 13: Score for root content of the fibre

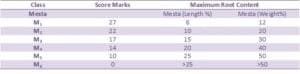

Grading of the Mesta fibre found in Maharashtra and Andhra Pradesh

The variety of Mesta which is grown in various districts of Maharashtra is Hibiscus Sabdariffa sub variety Race Ruber. This is an edible variety which is mainly grown for the consumption of its calyces. The calyces are widely used to produce jams, jellies, herbal tea etc. The fibre is a by-product which is sometimes discarded or sometimes used to make ropes and cordages. (Dedhia.E & Agarwal. J., 2014)

The second variety of Mesta which is from Andhra Pradesh is popularly known as AMV 2. It is sourced from NIRJAFT, Kolkata.

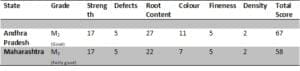

Table 14: Scoring Scheme for Mesta fibre found in Andhra Pradesh and Maharashtra

Results and Discussion

The quality of Mesta can be easily judged by the scoring scheme and the grade in which it falls will decide the end use of the yarn. Six physical parameters i.e., strength, defects, root content, colour, fineness and density are assessed for sorting out the fibres into six different grades. M1 is considered as very good quality whereas M6 consist of all the mesta fibres which do not conform to any grade like M2, M3, M4 and M5 but they are of commercial importance. Instrumental method is mostly used to determine the grade of the fibre to avoid any personal bias.

The Mesta fibre grown in Andhra Pradesh is of better quality than the fibre grown in Maharashtra. This could be due to many reasons like improper retting of the stems, unsuitable ways of extraction of the fibre or stage of harvesting. Though it is called a multipurpose crop its area in India is going down. Its cultivation is restricted to a fewer places in India. If proper grading system is implied in the industry it will enhance the value of the crop.

Conclusion

Mesta is obtained as a bark from two species namely Hibiscus Cannabinus and Hibiscus Sabdariffa. It occupies more than 80 percent of the cultivated area (www.indiastat.com). Mesta is referred as a multipurpose crop since every part has some use (D.P. Singh). Though it is a multipurpose crop its area in India is going down. To meet the growing demand of natural fibres the only way is to increase the productivity and make the crop of commercial importance. Grading the fibre is the first and very important step in the commercialization of a fibre and its products. Although the grading system for other fibre like cotton and jute are well known and used widely, the grading of mesta fibre is less known and is rarely used. It is concluded that the end usage of the fibre is dependent on its physical parameters and the parameters are in turn dependent on the quality of the fibre.

The grade of the mesta fibre found in Andhra Pradesh is better than the grades of the fibre found in Maharashtra. But this doesn’t mean that the grade of the fibre remains same for every season and every crop. The grades can be improved by improving the way of cultivating the crop, retting the stem, harvesting the crop. By this low grade of mesta can be improved by -2 grades thereby ensuring high return to the farmer and the industry is also benefitted by the availability of the fibre of superior quality.

References

- Singh, D.P. Mesta- Hibiscus cannabinus & hibiscus sabdariffa. N.d. Retrieved on Jan01, 2013 from https://assamagribusiness.nic.in/mesta.pdf

- Natural Fibres, Handbook with cultivation and uses(2009), NIIR Board of Consultants and Engineers, NIIR Project Consultancy Services, pp 151-155

- bis.org.in

- Bhaduri, S.C., Saha, S.K.(2008), Handbook on Grading of mesta fibre, National Institute of Research on Jute & Allied Fibre Technology (NIRJAFT)

- Agarwal, J., Dedhia, E. (2014, June). Current Scenario of Hibiscus Sabdariffa (Mesta) in India (Maharashtra). The International Journal of Humanities and Social Studies, 1(3), 129-135

- indiastat.com