Ajay Shankar Joshi, Prof.T.K.Sinha, Prof.Tanveer Malik

- Final Year Student, M.Tech in Textile Engineering ,Shri Vaishnav Vidyapeeth Vishwavidyalaya

- Professor, Shri Vaishnav Institute of Textile Technology, Shri Vaishnav Vidyapeeth Vishwavidyalaya

- Assistant Professor, Shri Vaishnav Institute of Textile Technology, Shri Vaishnav Vidyapeeth Vishwavidyalaya.

ABSTRACT

The quality garment is largely depended upon the seam quality, which is the very important feature of any form of fabric assembly using sewing operations. The investigation has attempted to find out the relationship between fabric elongation & stitch thread tension on the occurrence of seam puckering at different woven fabric samples. In this attempt the different types of four fabrics are used to analyzed the occurrence of seam puckering at three different of sewing thread tension .The tendency of seam puckering is evaluated by the calculation of seam puckering coefficient percentage at different tension level. This study brought the results that seam puckering is majorly depended upon the quality of material, sewing machine & skills of operator. The tendency of more seam puckering has been observed on the low & high sewing thread tension in all fabric samples whereas the level of seam puckering is high in case of polyester dominated fabric with high elongated value. That is the determination of correct sewing tension setting with performance of woven elongation for a desirable & undesirable occurrence of puckering.

Keywords: Fabric Elongation, Sewing thread tension, Seam puckering coefficient

INTRODUCTION

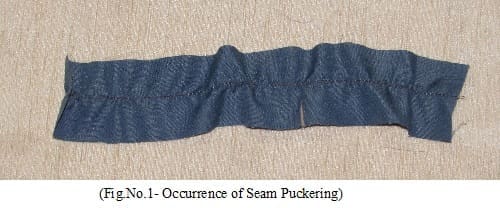

One of the most common interesting phenomena has encountered during garmenting that is Seam puckering .Seam puckering is the waviness structure of seam line in the fabric .Seam puckering effect is the resultant phenomena based upon the various mechanical properties of fabric and various technological parameters of sewing machine. [4,5,6]

The fabric elongation is also important aspect of the quality garmenting process because its affect the movement of fabric during garment .In the previous work [1-2], the fabric elongation played major role in quality consideration for clothing manufacturing. Other studies on seam puckering [7,9,10] exhibited guidelines for the garment manufacturers on seam performance.

This study provides the opportunity to evaluate the relationship between fabric elongation and seam puckering occurrence. In this study, combinations of fabrics samples are taken into consideration and sewn on warp and weft direction. Moreover, the influences of different fabric elongation value in warp &weft direction on seam performance & appearance would also be studied on the base of seam puckering coefficient.

MATERIALS AND METHODS

2.1 Materials:

2.1.1 Fabric:

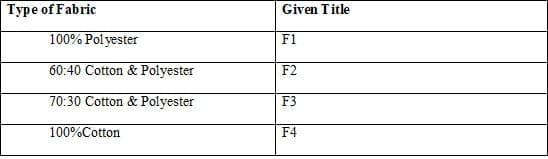

Commercially available and usually popular in market, the four types of shirting fabrics of polyester and cotton with different blend composition are taken into consideration for this study. The details of suiting fabric are-

Table no.1, Type of Fabric

- Sewing Thread:

The sewing threads are configured for number of plies, actual linear density, twist direction and tensile properties are used. Commercially available & usually popular polyester sewing threads of different colour with same number is used for this study.

(Table No.2-Type of Sewing Thread)

2.1.3 Sewing Machine:

The most common & popular single needle lock stitch sewing machine for simple sewing operation is used for study.During sewing sample preparation the static bobbin thread tension is kept constant with other technological parameters of machines are kept constant.

(Table No.3-Type of Sewing Machine)

(Figure no.2, Single Needle lock stitch machine )

2.2 METHODS:

2.2.1 Fabric sample preparation

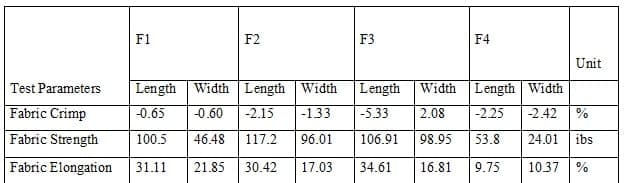

First Stage of this study, procurement of suitable fabric .In that we used 4 different fabrics mentioned in that Table no.1.The main fabric specifications are tested under the standard condition. , The different tests are carried out for this study fabric strength, fabric crimp, fabric elongation.

In second stage, we prepared the samples with measurement of 30*5 Centimeter (approximate 12*2 inches). We prepared the samples in warp & weft direction of each fabric samples.

(Figure no.3-Sample preparation)

2.2.2 Seam sample preparation

In next stage, we applied the stitch on separate warp & weft wise direction of fabric samples at single needle lockstitch sewing machine, Juki, Japan and produced a balance seam under the constant sewing speed, needle size, standard sewing thread counts, feed system and bobbin thread tension. In this stage we used three variables of sewing thread tension-

- Low sewing thread tension

- Medium sewing thread tension

- High sewing thread tension

The seam samples have prepared in such a way that the seams run through the middle of each samples. In that total number of seam samples are 4*2*3=24 that are each warp & weft of separate 4 different fabrics on 3 each level of sewing thread tension, low, medium & high . Seam samples have observed carefully & noted the puckering length (Shrinkage pucker) then

Calculate the seam puckering coefficient ,the formula is

Po= (L0-L1/L0)*100

Whereas L0 is initial sample length, L1 is sewn length of sample,P0 is seam puckering coefficient.

Thereafter we prepared and analyzed the different related tables of observed value of seam puckered with different fabric elongation value at 3 different sewing thread tensions. The observed data are exhibited by graphs.

2.2.3Fabric Testing

RESULTS & DISCUSSION

3.1 Study on fabric elongation and seam puckering coefficient at different thread tension before wash

3.1.1 Effect on Low Sewing Thread Tension

(Graph no.1 Fabric Elongation with Seam puckering coefficeint at Low Sewing thread tesnion warp wise )

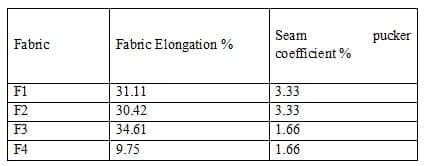

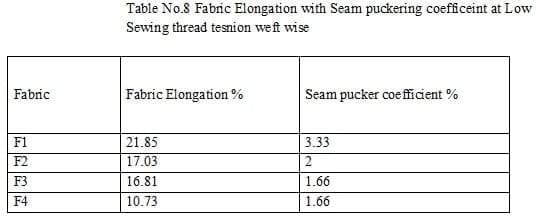

Table No.7 Fabric Elongation with Seam puckering coefficeint at Low Sewing thread tesnion warp wise

This graph showed that occurance of high seam puckering in F1,F2,F3 at high fabric elongated perecentage of ployester contained fabric at warp face and low seam puckering in F4 contained 100% Cotton,low elongated percentage

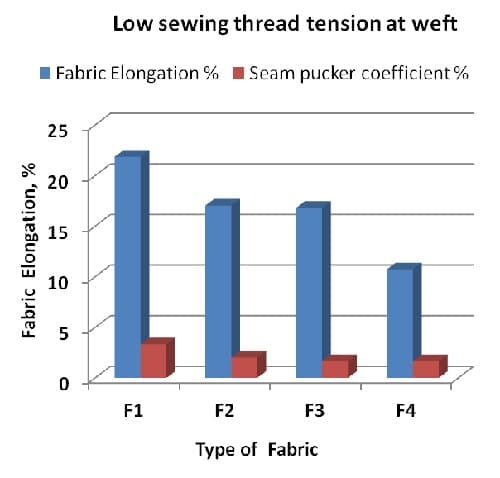

(Graph no.2 Fabric Elongation with Seam puckering coefficeint at Low Sewing thread tesnion weft wise )

This graph showed that occurance of high seam puckering in F1,F2 at high fabric elongated perecentage of ployester contained fabric at weft face and low seam puckering in F3,F4 contained 70% & 100% cotton respectvely.

3.1.2 Effect on Medium Sewing Thread Tension

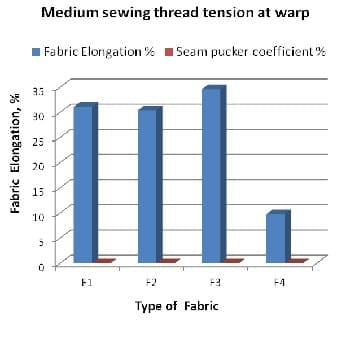

(Graph no.3 Fabric Elongation with Seam puckering coefficeint at

Medium Sewing thread tesnion warp wise )

This graph showed that no occurance of seam puckering

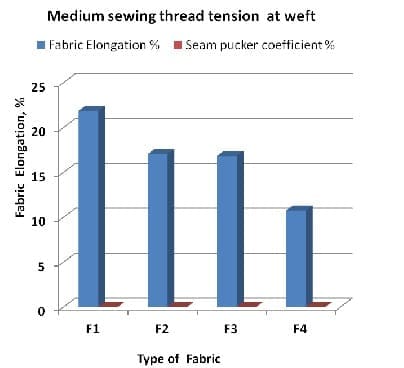

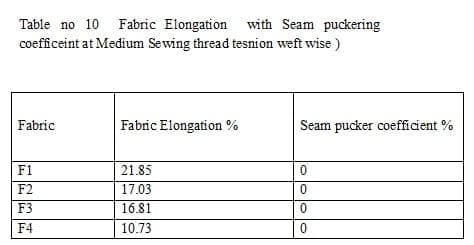

(Graph no.4 Fabric Elongation with Seam puckering coefficeint at Medium Sewing thread tesnion weft wise)

This graph showed that no occurance of seam puckering

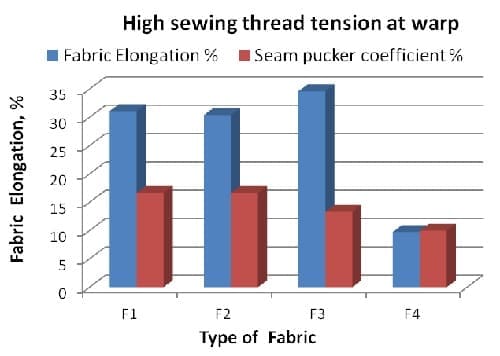

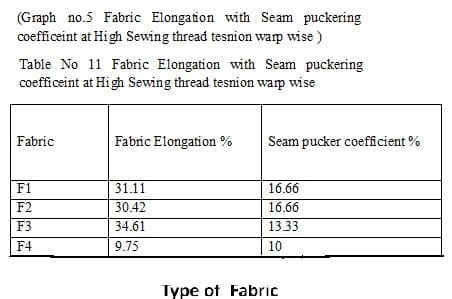

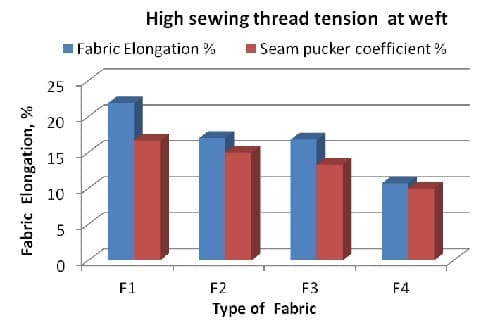

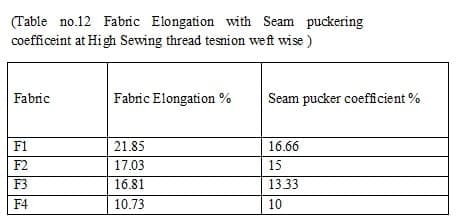

3.1.3 Effect on High Sewing Thread Tension

This graph showed that occurance of very high seam puckering in F1,F2,F3 with polyester contained fabric and 10% seam puckering showed by F4 contained 100% cotton .high fabric elongated fabric showed very high seam puckering coeffieienct at high sewing thread tesnsion .

(Graph no.6 Fabric Elongation with Seam puckering coefficeint at High Sewing thread tesnion weft wise)

This graph showed that occurance of very high seam puckering in F1,F2,F3 with polyester contained fabric and 10% seam puckering showed by F4 contained 100% cotton .high fabric elongated fabric showed very high seam puckering coeffieienct at high sewing thread tesnsion .

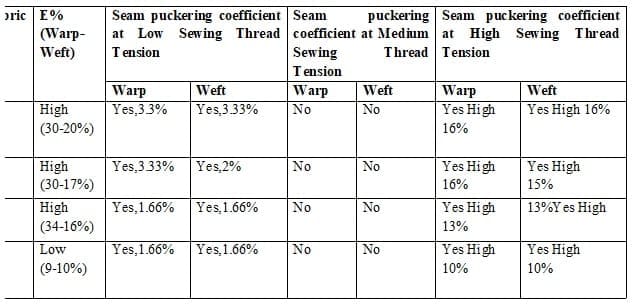

Table no.13 summary chart for relationship between fabric elongation and seam puckering coefficient at warp & weft wise

E%-Fabric Elongation percentage level

CONCLUSION

This study concludes that, in the application of High sewing thread tension that gives high percentage of seam puckering coefficient more than 10%. The high elongated valued fabric showed high occurrence of seam puckering in Low & High Sewing thread tension. The no occurrence of seam puckering in case of Medium sewing thread tension in all fabric samples .The tendency of seam puckering has observed less in weft wise direction as compare to warp direction .The tendency of seam puckering is also depended upon the type of fabric, fabric elongation, fabric structure, type of sewing thread , sewing thread tension, feed tension, and skill of operator.

REFERENCE

- Aušra Adomaitienė,Eglė Kumpikaitė, “Analysis of Mechanical Properties of Fabrics of Different Raw Material”, MATERIALS SCIENCE (MEDŽIAGOTYRA). Vol. 17, No. 2. 2011

- Jahan I,”Effect of Fabric Structure on the Mechanical Properties of Woven Fabrics”, Advances research in Textile Engineering, October , 2017

3.Carr,Latham, “Technology of Clothing manufacture, Blackwell publication ,2008

4.S.Galusysnki, “Seam Pucker by S.Galusynski”,Sawtri special publication,2007

- Ruth E. Glock, Grace I. Kunz,.Apparel Manufacturing: Sewn Product Analysis (3rd Edition) Prentice Hall published

- Vaida Dobilaitė ,Milda Jucienė, Eglė Mackevičienė, “The Influence of Technological Parameters on Quality of Fabric Assemble”, MATERIALS SCIENCE (MEDŽIAGOTYRA). Vol. 19, No. 4 ,2013

- V. Dobilaite, M. Juciene, “The influence of mechanical properties of sewing threads on seam pucker,” International Journal of Clothing Science and Technology, vol. 18, no. 5, pp. 335–345, 2006

8.F. Fathy ,Saied Ebrahim, “The Impact of Sewing Threads Properties on Seam Pucker”, Journal of Basic and Applied Scientific Research,(2012)”

- A.K. Choudhary, Amit Goel, “Effect of Some Fabric and Sewing Conditions on Apparel Seam Characteristics, Hindawi Publishing Corporation. (2013)

- K.P.S. Cheng, K.P.W. Poon, “Studies on the Seam Properties of Some Selected Woven Fabrics, Textile Asia,Vol.33,2002

- Principles of Textile Testing: An Introduction to Physical Methods of Testing Textile Fibres, Yarns and Fabrics,J.E.Booth,butterworth,1986