Satish Y Patil, Yashovardhan M Indi

Department of textiles, DKTE’S Textile & Engineering Institute Ichalkaranji-416115

Correspondence e-mail: [email protected]

ABSTRACT: – Textile industry is the largest one next to agricultural in the country where most of the people are employed. Wet processing of cotton required high quantity of water and energy for desizing, scoring and bleaching process. Conventionally these processes are carried by using harsh chemical which is give water pollution. In order to control water pollution enzyme can be used of processing of cotton. At a same time enzyme required low temperature which is give energy conservation. This study is focused on comparative analysis between conventional desizing with enzyme desizing, alkaline scouring with bio scouring, conventional bleaching with bio bleaching and conventional combine scouring bleaching with bio combine scouring-bleaching. So advantages of bioprocessing can be described in terms of ecology as well as economy.

Keywords: – Enzyme, Conventional processing, Bio scouring, Bio bleaching.

Introduction

Cotton is the most important cellulose fibre in textile. But natural cotton fibre contains some impurities. Cotton fibre is highly hydroscopic also slightly coloured .In further processing cotton should absorb water to get satisfactory result. At a same time colour of cotton should be white before dyeing to achieve final required colour. Hence in order to get absorbency and whiteness scouring and bleaching process become important one. [1]

Traditionally scouring of cotton was carried out by using caustic soda and sodium carbonate. Both this chemical having high pH and increase load on ETP and because of higher concentration of alkali tenacity of cotton decrease. Bleaching of cotton also required high alkaline pH and high concentration of H2O2 reduces tenacity of cotton. Hence in order to save water this two process carried out in one bath As this two process done in one bath load over ETP get reduces but effluent which is generated having higher pH and total organic compound .

To reduce the water pollution in textile wet processing, we have to reduce the use of such high concentrate chemical. Also such chemical are available in market which does not affect the properties of cotton. One of the chemical which can be used in wet processing is enzyme. Use of enzyme in wet processing reduces the water pollution. Also required temperature is low as comparative to conventional processes hence use of energy is also low. Enzyme work on specific substrate it will not affect the properties of cotton and most important thing is there is less effluent generation. If bio-scouring and bio-bleaching could be combined into one process, large amounts of water, energy, time and auxiliary agents would be saved

Enzyme

Enzyme is a Greek word enzymos having meaning ‘in the cell’ or from the cell’. Enzymes are the high molecular weight protein and it is a made up of more than 250 amino acid . They are biocatalyst which increases the rate of reaction. Enzymes are very specific in their action and controlled by concentration, time, temperature and pH. Enzymes are obtained from plants, microorganism and animal. Enzyme converts substrate (beginning molecule) in to product (different molecule). Enzymes are classified as follow

- Oxidoreductases – oxidation, reduction reaction

- Transferase – Transfer of functional group

- Hydrolases – Hydrolysis reaction

- Lyases – Addition to double bond

- Isomerses – Isomerisation

- Ligases – Formation of bond

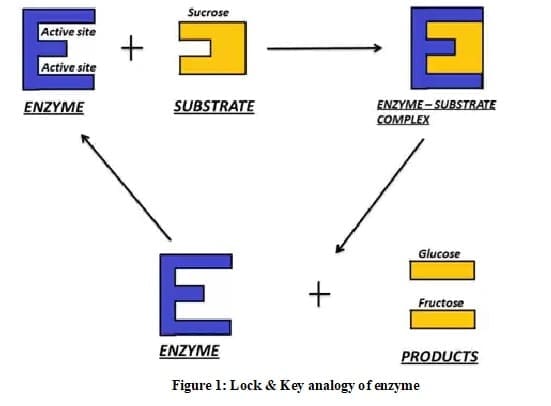

The enzyme contains three dimensional activity centers in a structure. The active side is a one part of enzyme and get combine with substrate (beginning molecule) and forms a complex to catalyze a reaction. Finally substrate converted in to final product (different molecule) as shown in fig 1[4]

Textile is one of the growing industries that consume lots of water energy and harsh chemical. The enzyme can be used for various applications in textile wet processing like desizing, Scouring, Bleaching, dyeing Bio-polishing, Peroxide killer, Anti shrink treatment for wool, Printing and finishing. Also combination of two processes like desizing and scouring, scouring and bleaching Desizing-scouring-bleaching is possible by using enzyme

Enzyme desizing

Conventionally desizing is done by using hydrochloric acid or oxidizing agent. These chemicals reduce the strength of basic fabric by attack on starch as well as cellulose. Enzyme is the one option to avoid reduction in tensile strength of fabric . Fabric is padded through solution containing 1 gpl amylase and 0.5 gpl sodium chloride at 400C. For this process required pH is acidic (5.5). Fabric is padded by using padding mangle (100% expression) and batched for 24 hour at ambient temperature. The Desized fabric washed twice with hot water and once with cold water and then dried . Desizing by exhaust method is also possible where fabric is treated with 1gp amylases enzyme at 700C for 60 min with acidic pH (5.5).

Enzyme desizing gives following advantages over conventional desizing method [3

- Less tensile strength loss

- No hydro cellulose formation

- Less shrinkage problem

- Less time required

- No fibre damage

- Less weight loss

- Less water pollution

Enzyme scouring

Cotton could not absorb water during processing within specific time (3 Sec) because of 0.4-1 % oil fat waxes in their structure. Removal of oil fat and waxes become so important to get satisfactory results in further processing. Conventionally scouring of cotton is done by using sodium hydroxide which is highly alkaline in nature. Along with impurities it break the bonds cellulose causes reduction in tensile strength. Use of highly alkaline chemical causes high COD (chemical oxygen demand), BOD (biological oxygen demand) and TDS in wastewater . Conventional scouring process is commonly used in industry but now-a-day it gives bad effect on environment. Conventional can be replaced by eco-friendly enzyme scouring process . Fabric is treated with pectinase 5 gpl enzyme at 550C in alkaline pH (8) for 60 min. this give satisfactory results and absorbency is depend on concentration of enzyme. Weight loss is less than the conventional scouring which means no strength loss in fabric. Enzymatic scouring of cotton fabric can be done by using various enzymes like cellulose, lipase, pectinase etc. Whiteness index obtained by the enzyme scouring is 8-10% more as compare to conventional scouring also no loss in tensile strength. Enzyme scouring give less BOD, COD, TDS as compare to conventional process. This method can be used for cotton as well as cotton blends by changing the enzyme . Alkaline pectinase enzyme can be combined with cellulose enzyme to get more absorbency. This process gives more absorbency but decrees the tensile strength of fabric [8]. Advantages of enzyme scouring are less energy required, less water required, low cost of chemical, good absorbency, less strength loss, better dyeing effect. Lower effluent load soft feel same depth of colour. Also it can be combined with peroxide bleaching which reduce the cost of process .

Enzyme Bleaching

Bleaching is the process in which natural colouring impurities are removed to get final colour in dyeing. H2O2 is mostly used as bleaching agent in bleaching of natural, synthetic as well as blends of textile material. Mostly pH of H2O2 bleaching is 11.5 which is highly alkaline at a same time temperature required is also about 90oC . H2O2 is not completely removed from the fabric which may give problem like uneven dyeing, hydrolysis of reactive dye etc. It required several washing treatment to remove H2O2 from fabric. Catalase enzymes are used to remove H2O2 from the fabric which removes total H2O2 from fabric by complete decomposition of hydrogen peroxide. It converts residual peroxide in to water and oxygen. In order to save water and energy bleaching can be carried out by using glucose oxidase enzyme which is used as alone or can be combined with peroxidases also. H2O2 generated from glucose oxidases get combined with peroxidases which give better whiteness index as compare to conventional bleaching agent Desized and scoured fabric were bleached by using glucose oxidase enzyme. The whiteness index is 73% more than scoured fabric. Satisfactory degree of whiteness can be achieved by using glucose oxidase . Enzymatic bleaching with paracetic acid gives better result than conventional process at neutral pH and lower temperature i.e. 650C It give high whiteness, less strength loss and good water absorbency compare to traditional process .

Enzyme combine scouring-bleaching

In a today’s competitive world energy conservation is the important to minimize final product cost as well as environmental degradation also. In order to save energy combination of two process and process modification become essential. One such approach is combination of scouring and bleaching in one process. Temperature of process can be decrease up to remarkable level by using some activator like potassium persulphate . Use of ecofriendly chemical becomes so important because of increasing cost of water, energy and environmental aspect. Combined use of α-amylase and hemicellulose/pectinase in the pre-treatment of cotton gives combine desizing and scouring with better results than conventional and individual process. Glucose oxidase enzyme can be combine with other enzyme to get satisfactory result in bleaching.One bath bio scouring and bleaching of cotton give better results of absorbency, reduce load ETP and gives less degradation of cotton than alkali scouring and bleaching .Combine scouring and bleaching by using scouring enzyme and hydrogen peroxide give same effect that of individually process . Traditionally scouring and bleaching process carried out at the temperature 1200C in higher alkaline pH. It took lots of energy as well as water in further washing process of fabric which is converted in an effluent. In order to save energy and water higher alkaline chemical should be replace by ecofriendly chemical. Pectinase enzyme is an alternative to sodium hydroxide in scouring which give same result at low temperature. H2O2 can be replacing by using peroxidases, laccase /mediator or glucose oxidase. Bio-scouring and bio-bleaching can combine in one bath. Fabric is treated with scouring and bleaching enzyme at 650C for 60 min. Increase in temperature of this bath give better degree of whiteness. This process leads to less time, less energy, better results than conventional process .

Conclusion

Use of enzyme is one of the methods to replace the conventional processing chemical which create water pollution. Amylase enzyme gives satisfactory results as compare to acid desizing. Enzymatic scouring can be carried out at low temperature as compare to conventional alkaline scouring. It reduces the water pollution that is les COD, BOD and TDS. Also weight loss is less as compare to conventional process. H2O2 can be successfully replaced by using glucose oxidase enzyme and catalase enzyme can be used for the removal of residual H2O2 from the fabric. Combine scouring and bleaching of cotton by using enzyme save water and energy. This process required less energy and less water as compare to conventional process.

References

- S. P. Mishra,Cotton, A Text Book of Fibre Science and Technology”Page 71-87

- Cited on https://textilelearner.blogspot.com/2013/03/enzyme-and-its-applications-in-textile.html

- Ketan Verma “Enzyme and its benefits for textile process specific load on effluent as well as improvement in fabric” Colourage Dec 2015 38-44

- Vaibhav Nagaje, Ashish Hulle “Enzyme in textile processing” Colourage, December 2004,33

- Bikash Jena, Bishnu Priya Das, A. Khandual , Sanjay Sahu & Lingaraj Behera “ Eco friendly processing of textile” Elsevier Material Today Proceeding 2 (2015) 1776-1791

- Klaus Opwis, Dierk Knitte, Eckhard Schollmeyer “Use of enzyme in pretreatment of cotton” Deutsches Textilforschungszentrum Nord-West e.V. Adlerstr. 1, D-47798 Krefeld, Germany

- Mahesh sharma “Application of enzyme in textile processing” Colourage, January 1993

- Ali Hebeish , Mohamed Hashem , Nihal Shaker, Mohamed Ramadan, Bahiya El-Sadek,Marwa Abdel Hady “New development for combined bioscouring and bleaching of cotton-based fabrics” Elsevire Carbohydrate Polymers 78 (2009) 961–972

- Tzanko Tzanov, Margarita Calafellb, Georg M. Guebitzc, Artur Cavaco-Pauloa, “Bio Processing of Cotton Fabric” Journal of Enzyme and Microbial Technology 29 (2001) 357-362

- N. Mahapatra “Use of enzyme in textile processing” Asian Dyer, july 2010, 53

- Azizul Hoque, Abu Yousuf Mohamamd Anwarul Azim “Using Enzymes as an Aid of Better and Eco-Friendly Scouring Processing” American Journal of Engineering Research, Volume-5, Issue-6, 167-182

- S. K. Laga, Miss. Geeta K. Chunari “Bioscouring: An overview” Colourage, April 2015,39

- A Edvin Sunder, G nalankilli “Bio-scouring” Asin Textile Journal, January 2002

- K. Patra, Gaurav Agrawal, Sumit Garg “ Enzymatic scouring & bleaching compatibility of cotton” The Indian Textile Journal, April 2004/25

- Sonia Hossain, Md. Koushic Uddin “comparative analysis between conventional pretreatment and bioprocessing” International Journal of Engineering & Technology vol:11 no:3

- Nina Spicka and Petra Forte Tavcer “New Combined Bio Scouring and Bio Bleaching Process Of Cotton Fabric ” Material and Technology 47 (2013) 4, 409-412

- I. Wasif , Y. M. Indi “Combined scouring-bleaching of cotton using potassium persulphate” Indian Journal of Fibre and Textile Research, vol 35, December 2010, pp353-357

- Geeta N. sheth, Aparna A. Musale “Single bath bio-scouring and bleaching of cellulosic yarn knitted and woven fabric”, Colourage nov 2015