Abstract

Leather industry is one the leading industries in textiles. It produces large amounts of waste during the manufacturing process and after use of leather fabric by consumers. This industry is one of the largest waste producing industries. Almost 20% of worldwide waste from leather is generated in Asia. This can be very harmful to the aquatic life. It occupies large landfill space. The waste should be recycled to minimize the environmental impact. It produces solid waste and liquid waste during processing. There are a lot of studies done on leather recycling and reusing the leather products. Some methods to recover energy from the heat and energy which is generated during leather processing. The restyling technique also helps reuse and reduce the waste.

Introduction

Leather has been treated with chemicals to preserve and make it suitable for use as clothing, footwear, handbags, furniture, tools, and sports equipment. The consumption of leather products by humans is very commonly used. The primary raw material for any leather processing industry is derived from slaughter houses and waste from the meat industry. This raw material is processed and converted into usable leather in tanneries. Hence, the tanning industry is considered as one of the primary leather processing units in the entire leather industry. The chemical treatment called tanning, converts the otherwise perishable skin to a stable and non-decaying material. Tanning agents include vegetable tannins (from sources such as tree bark), mineral salts (such as chromium sulphate), and fish or animal oils. In this tanning process maximum leather waste is generated; this waste is further used for generating heat and energy [1].

Process of modern leather Manufacturing

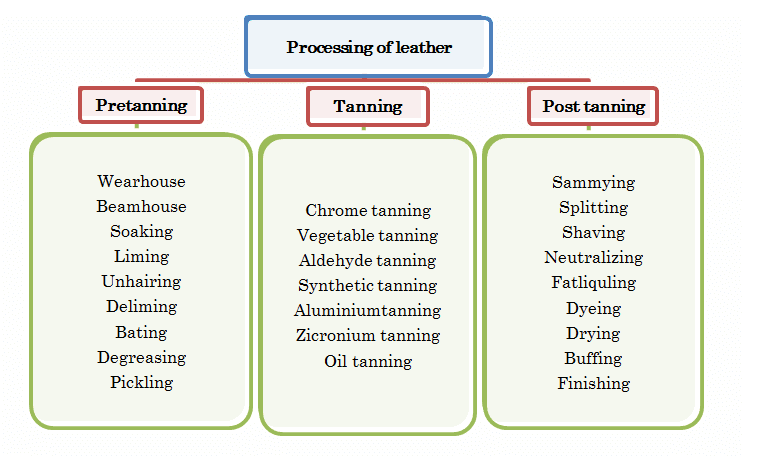

The leather production is a very lengthy process that involves several steps before tanning. The most important stages in converting the raw animal hide to leather are listed below [2][3]. The modern commercial leather-making process involves three basic phases:

- Preparation for tanning,

- Tanning and

- Processing tanned leather [4]

Fig. No.1 lists down the different steps in the Processing of leather.

Fig 1. Processing of leather [3]

Some of the harmful chemicals in the processing of leather are used in processing are listed below:

Table No. 1 Harmful chemicals use in leather industry [4]

| Name of Chemical | Use | Target organs |

| Chromium sulphate | Principal raw material used in the production of chrome tanning materials for the leather industry like Chrome-tanning salts | Blood, kidneys, heart,

lungs, eyes and carcinogen |

| Chromium | used for dyeing | Kidney, CNS, |

| Short chain chlorinated

paraffin’s (PBT) |

Additive for the leather treatment (renders smoothness to leather), leather clothing and belts and as a leather oiling agent. | Liver, kidney, thyroid and carcinogen |

| Cobalt dichloride | Used in leather dyeing and

finishing as well found in tanned leather |

Lungs, liver, kidney, heart, skin |

| Methyl isothiazolinone | Biocide, microbiological protection | Skin, eyes and carcinogen |

| Formaldehyde HCHO

Heavy metals Arsenic |

Leather finishing | Eyes, lungs and carcinogen |

Eco-friendly alternatives for the hazardous chemicals used in leather processing

The consumer consciousness and strict regulations by the worldwide authorities require leather products with the lowest possible risk for the environment. Instead of using chromium sulphate we can use vegetable tannin like quebracho, chest nut, behra nuts in the tanning process, which gives a more stable leather and it is eco-friendly method [6]. Nitrocellulose lacquer emulsions can be successfully replaced with castor oil, which maintains the typical lacquer emulsion properties like glossy touch, softness and elasticity. Enzymes, amino acids or oxazolidine can be used as an alternative in tanning processes. As an alternative for the solvent N-Methyl pyrrolidone high wear top coat acrylics being free of solvents have been used . Formaldehyde in leather finishing is not only used as a cross linker for case in top coats but also as a biocide. Finishing chemicals may contain formaldehyde even when no formaldehyde was used for the production, as many raw materials are preserved in formaldehyde base. To overcome this problem use of formaldehyde scavengers can be adopted as in the case of some Wet End Chemicals Inorganic heavy metal pigments like lead chromate, cadmium sulphide and others can be replaced by organic pigments or pigments. We can use silver nanoparticles in the tanning process which improve the mechanical and the physical properties. It can also be used as an antimicrobial and UV resistant application [5][7].

Waste management in leather industry

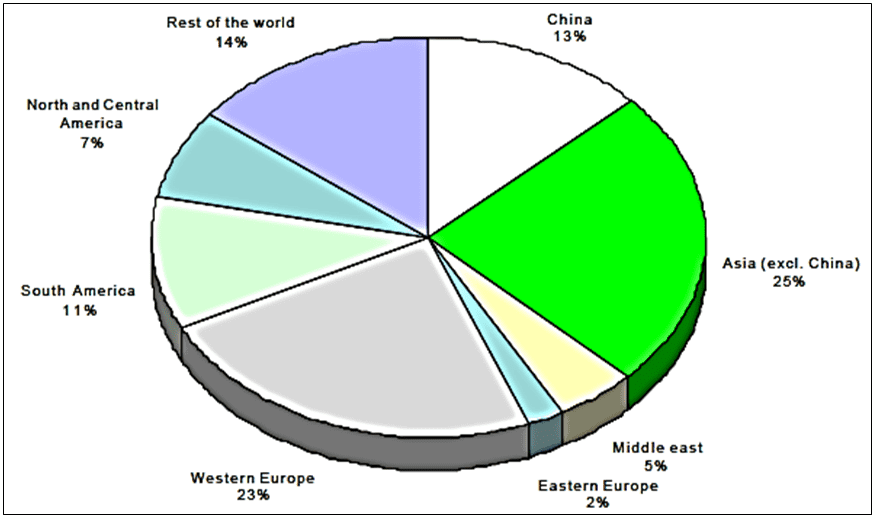

The Fig. No.2 below gives the volume of waste generated from the leather Industry. The largest amount of waste comes from the Asian Continent. The waste generated from the leather Industry from China alone contributes to 13% while, one fourth of the global waste comes from the other Asian countries together.

Fig. No. 2 Waste generated from leather [15].

Two types of waste generated in leather industry

- 1.Post-consumer waste: It is also called house-hold waste and dirty waste. Any worn out, damaged and out of fashion apparel and textile products, which are discarded and no longer in use by the wearer. They are sometimes given to charities but more typically are disposed of into the trash and end up in municipal landfill.

- Pre-consumer waste: is waste generated during the manufacturing process. Waste originates from all stages of leather making process, such as fine leather particles, residues from various chemical discharges and reagents from different waste liquors (Effluent), comprising of large pieces of leather cuttings, trimmings and gross shavings, fleshing residues, solid hair debris and remnants of paper bags. Out of 1000 kg of raw hide, nearly 850 kg is generated as solid wastes in leather processing. Only 150 Kg of the raw material is converted to leather [9].

- Over 80 % of the organic pollution load in BOD terms comes from the pre-tanning process this mainly comes from degraded skin and hair matter. During the tanning process at least 300 kg of chemicals are added per ton of hides. Excess of non-used salts will appear in the wastewater [8].

- A large amount of waste generated by tanneries is discharged in natural water bodies directly or indirectly through two open drains without any treatment. The water in the developing countries, like India and Bangladesh, is polluted to such a degree, that it has become unsuitable for public use. In summer, when the rate of decomposition of the waste is higher, serious air pollution is caused in residential areas by producing intolerable obnoxious odours [10].

- Tannery wastewater and solid wastes often find their way into surface water, where toxins are carried down stream water. Chromium waste can also leak into the soil and contaminate groundwater systems [9].

Steps to improve the waste management in the leather industry

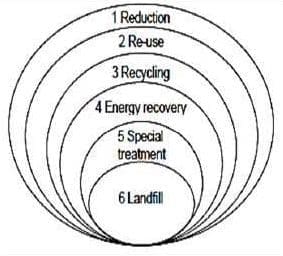

Fig. No. 3 Steps to improve waste management [8]

- Reduce: We should buy only what we need because a better way to reduce waste is by not creating it. Reducing the amount of buying is the most significant of all the options to manage waste. The key is to only purchase goods that we need and in the right amount. If we generate an excess of products in the first place, we do not have to extract raw resources, manufacture goods from scratch, come up with shipping materials, utilize additional resources for shipping, and then devise ways to dispose of them [12].

- Reuse: If we have to acquire goods, try getting used ones or obtaining substitutes. Waste, after all, is in the eye of the beholder. One person’s trash is another person’s treasure. If we really look at things we are throwing away, we can learn to see them as materials that can be reused to solve everyday problems and satisfy everyday needs. Most of us, however, have not even begun to exploit the resources in our trash. Once you have made up your mind to use trash for positive uses, you can begin to brainstorm and generate ideas. Reusing saves money, conserves resources, and satisfies the human urge to be creative [12].

- Recycle: When we discard waste, find ways to recycle it instead of letting it go to landfill [12][13].

Old leather recycling

- Take gently-worn leather goods to be fixed professionally. General shoe and bag repair shops often have the equipment to make repairs including patching, stitching and stretching and can restore your leather goods to extend their life. Do not buy new, fix your favourites instead as a sustainable option.

- Take leather scraps to a recycling outlet for resale.It is good option of taking leather scraps to be resold to others for many purposes including craft projects. Some industrial level companies also recycle leather to be used again in their products.

- Donate worn leather shoes to a local charity.Many non-profit organisations will collect used footwear and pass it on to those in need in the community. Before giving away, we should carefully inspect and clean our shoes to appraise their quality for reuse.

- Donate clothes and bags. Use the internet to find a collector in your neighbourhood and give back to your community [14].

Upcycling Leather Items Creatively

- We can use old belts to make a ‘shelf’.Once we have finished wearing a belt, we can still use it in a variety of handy ways around the home, including creating a unique hanging shelf. It’s easy, cheap and saves space in your room.

- We can create funky new handles for a handbag from leather waste.

- We can make a set of new napkin rings for your dining room table.

- Also a one of a kind rug for the living room can be make from leather waste. If we have enough scraps, we can make a large rug for the living room [14].

- Energy Recovery

UASB technology

The heat and energy generation can be achieved by treating the wastewater effluent using Upflow Anaerobic Sludge Blanket Technology (UASB) with Sulfur Recovery Plant. The UASB technology has been well-known for treating waste water primarily because of its low sludge production. The major advantage of this technology is that it provides a potential possibility to generate energy, rather than consuming the same while treating the waste water using this technology for treating tannery waste water. Because of the high sulfate content, it results in generation of methane gas, contaminated with hydrogen sulfide,. An improved system has, therefore, been developed whereby the sulfate is completely removed as elemental sulphur. This also reduce the COD by 60% and TDS by 90%

UASB uses an anaerobic process while forming a blanket of granular sludge which is suspended in the tank. Wastewater flows upward through the blanket and is processed by the anaerobic microorganism, eventually aggregates form into dense compact biofilms referred to as granules and Biogas with a high concentration of methane is produced as a by-product, and this may be used as an energy source, to generate electricity [11].

Biomethanation for Solid Waste Disposal of leather

Solid wastes generated by the leather processing industry are posing a major challenge. Tannery, fleshings, which are the major solid wastes emanating from the beam house of a tannery, are subjected to biomethanation. It is a process whereby the fleshing is liquified completely biologically. The resulting liquefied fleshing is treated in anaerobic reactors to produce biogas. Any anaerobic reactor like the UASB reactor can be used for this purpose.

Biomethanation is a process by which organic material is microbiologically converted under anaerobic conditions to biogas. Three main physiological groups of microorganisms are involved in fermenting bacteria, organic acid oxidizing bacteria, and methanogenic archaea. Microorganisms degrade organic matter to methane and carbon dioxide. Biomethanation has strong potential for the production of energy from organic residues and wastes. It will help to reduce the use of fossil fuels and thus reduce CO2 emission [11].

Special treatment

Regenerated leather (RGL)

Preparation of leather like material, regenerated leather from finished leather wastes is economical and helps in reducing environmental pollution. Incorporating plant fibers into RGL enhances its mechanical properties. Plant fibers are exploited as reinforcement materials owing to their low cost, fairly good mechanical properties, high specific strength, non-abrasive, eco-friendly and bio-degradability characteristics. Fiberized leather wastes and PFs were mixed in various proportions to prepare regenerated leather composites. Plant fibers like coconut, sugarcane, banana and corn silk were used for a study, regenerated leather composites prepared using leather waste and coconut fiber (50:40 ratio) proved to be a better composite with potent properties. Regenerated leather composites are promising for the preparation of leather goods and footwear materials in addition to its cost-effectiveness and environmental pollution abatement [16].

Benefits of recycling

Reduce, Reuse and Recycling decrease the landfill space requirements. This will result in pollution avoidance, reduced consumption of energy, chemicals and water. There will be a reduced demand for dyes. Overall, reducing the need for processing virgin materials [15][17].

Challenges with Recycling

Although the recycling of materials creates a circular economy and therefore increases sustainability, there are potential challenges to recycling leather. Theoretically, offcuts of leather created within the leather manufacturing process are more easily recycled than final products at the end of their life. However, with a potential lack of market for offcuts, this product is often disposed of in the tannery. Although some brands are making use of offcuts or combining leather offcuts with other materials to create a combination material, this is not currently widespread and often this material is used for certain products only. There is an extra cost to recycling goods. If the market is not willing to pay the increased cost for a recycled product, it is unlikely that companies will invest [18].

Conclusion

As the amount of use of leather increases, the waste generated from the leather is inevitable. Research Institutes and Industries are keen to search various textile waste recycling opportunities at the industrial level for both economic and environmental reasons. The waste generated during tanning process of leather manufacturing contain harmful chemicals which pollute the ground water and is a hazard to living organisms. To overcome this problem, there are alternative chemicals that can be used in the tanning process. These alternatives give better results, are safe to living beings and sustainable.

Some Research Institutes have developed new technologies related to heat and energy generation from toxic solid and liquid waste that is generated in leather industry. With the help modern technology, leather goods can be recycled more efficiently with minimum waste products.

References

- Shilpa Goel ‘An in-depth study of India’s leather industry with special reference to export prospects of leather products’ International Journal of Advanced Research in Management and Social Sciences, January 2014.

- Karanam Sai Bhavya Raji P, Jenifer Selvarani A ‘Leather Processing, Its Effects on Environment and Alternatives of Chrome Tanning’ International Journal of Advanced Research in Engineering and Technology (IJARET) Volume 10, Issue 6, November-December 2019, pp. 69-79.

- Moses A Ollengo and Esther W Nthiga Peter Maina, (2019), ‘Trends in leather processing’: A Review, International Journal of Scientific and Research Publications, 9 (12).

- Sumita Dixit, Ashish Yadav, Premendra D. Dwivedi, Mukul Das ‘Journal Toxic hazards of leather industry and technologies to combat threat: a review’ Journal of Cleaner Production (2015) 39-49.

- Seggiani, M. Puccini, S. Vitolo, C. Chiappe, C. S. Pomelli& D Castiello ‘Eco-friendly titanium tanning for the manufacture of bovine upper leathers: Pilot scale studies’ Clean Technologies and Environmental Policy volume 16, pages1795–1803 (2014).

- ‘Leather processing, its effects on environment and alternatives of chrome tanning’ laeme publication international journal of advanced research in engineering and technology (ijaret) volume 10, issue 6, november-december 2019, pp. 69-79, article

- R. Souza, and M. Gutterres, ‘Application of enzyme in leather processing,A comparison between chemical and coenzyme processes’. Brazilian Journal of Chemical Engineering, 29(3), 2012, 473-481.

- Hidalgo Ruiz, ‘Wastes generated in the leather products industry’ fourteenth session of the leather and leather products industry Panel Zlin, Czech Republic 13-15 December 2000.

- Agarwal, R., Sharan, M. (2015). ‘Municipal textile waste and its management’, Research journal of Family, Community and Consumer Sciences. Vol. 3 (1).

- Ozgunay H, Colak S, Mutlu MM, Akyuz F, ‘Characterization of leather industry waste’. Pol J Environ Stud 6:867–873, (2015).

- M. Sivaram and Debabrata Barik, ‘Toxic Waste From Leather Industries’ Department of Mechanical Engineering, National Institute of Technology Pondicherry, Karaikal, U.T. n book: Energy from Toxic Organic Waste for Heat and Power Generation (pp.55-67).

- Fahzy Abdul-Rahman, ‘Reduce, Reuse, Recycle: Alternatives for Waste Management’ Guide G-314, M State Uuniversity, Florida Cooperative Extension Service publication HE 3157. January 2014.

- Rick leblanc ‘The Basics of Textile Recycling’ Growth of Textile Recycling Promises to Divert More Material from Landfills’. Updated December 30, 2020 https://www.thebalancesmb.com/the-basics-of-recycling-clothing-and-other-textiles-2877780.

- ‘How to Recycle Leather’ Co-authored by wikiHow Staff Last Updated: March 29, 2019 https://www.wikihow.com/Recycle-Leather#References

- Bairagi, N. ‘Recycling of textiles in India’. Department of Knit wear Design, National Institute of Fashion Technology, Bengaluru, India, Textile Science and Engineering, (2014).

- Rethinam, Senthil, Tiruchirapalli, Sivagnanam, Uma, Bhabendra Nath Das& Thotapalli Parvathaleswara Sastry ’Recycling of finished leather wastes: a novel approach’

- Islam, M.M., Khan, M.M.R. (2014). ‘Environmental sustainability evaluation of apparel product: A Case study of knitted T-shirts. Journal of Textiles, Hindawi Publishing Corporation, Article id 643080, 6 pages

- Clean Technologies and Environmental Policy,(2015), Volume 17, pages187–197.

https://wigreports.com/beginner-guide-to-paraben-sulfate-free-hair-products/