Introduction

In the strictest sense of the term, the ‘Leather Industry’ covers the preserving of the rawhide after the slaughterhouse and the tanneries which process the raw skins into durable leathers. India is the second-largest producer of footwear in the world. In India, there is a high earning foreign exchange and in leather is in the top 10 sectors.

Why the leather industry is in the top 10 sectors?

World’s 20% cattle production happens in only India, which means India is producing maximum raw material and in India there is maximum skill manpower, and using upgrade technology, international standard, etc. And that is the reason for India’s share increases in competition.

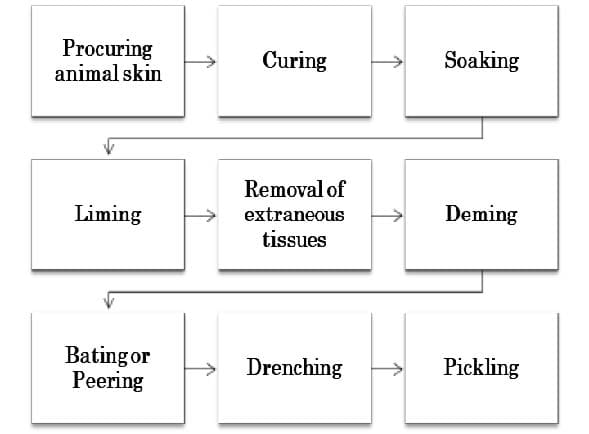

Process of Tanning: The flowchart below shows the complex process of Tanning Leather

Procuring animal skin: The animal is killed and skinned before the body heat leaves the tissues.

Curing is the preservation of hides. Curing can be performed in different ways.

By Salting: Animal Skin is composed of 60-65 % water, 30-32 % protein, approximately 10 % fat, and 0.5 – 1 % minerals. It prevents putrefaction of the protein (collagen) from bacterial growth. Salt removes water from the hides and skins using a difference in osmotic pressure. In wet salting, the hides are heavily salted, then pressed into packs for about 30 days. In brine-curing, the hides are agitated in a saltwater bath for about 16 hours. Curing can also be accomplished by preserving the hides and skins at very low temperatures.

Pre-tanning or bean house operations

Soaking: The skins are de-haired, degreased desalted, and soaked in water for six hours to two days. To prevent damage of the skin by bacterial growth during the soaking period, biocides such as dithiocarbonates, 2 –thiocyanates, Ethylbenzothiazoline, etc. To protect wet leathers from microbial growth.

Liming: After soaking the hides are treated with milk of lime supplemented by sodium sulphide, cyanides, amines, etc.

Unhairing and Scudding: Unhairing agents are used such as sodium hydroxide, sodium hydrosulphide, calcium hydrosulphide Dimethylamine, and sodium sulfhydrate. Most of the hair is then removed mechanically, initially with a machine and then by hand using a dull knife a process known as scudding.

Deliming and Bating: Depending on the end-use of the leather, hides are treated with enzymes to soften them, a process called bating. Enzymes act properly so the pH of the collagen is brought down to a lower level so the enzymes may act on it, in a process known as de- liming.

Pickling: Once bating is complete, the hides and skins are treated first with common salt (sodium chloride) and then with sulphuric acid in case a mineral tanning is to be done. This process is known as Pickling. The salt penetrates the hide twice as fast as the acid and checks the ill effect of the sudden drop of PH.

Chrome Tanning: Chromium(ll) sulphate and sodium bicarbonate (base) are added to this process. Chromium(ll) sulphate is used as a tanning agent. Chromium(ll) sulphate dissolves to give the hexaaquahromium (ll) cation, which at higher pH undergoes processes called olation to give polychromies(ll) compounds that are active in tanning, being the cross-linking of the collagen subunits. The cross-linkage of chromium ions with free carboxyl groups in the collagen. It makes the hide resistant to bacteria and high temperature. The chromium-tanned hide contains about 2-3% by dry weight of Cr

Vegetable Tanning: Hides are kept immersed in Tannin liquor for several weeks in series of vats with increasing concentration of tannins. Tannins bind to the collagen proteins in the hide and coat them, causing them to become less water-soluble and more resistant to bacterial attack. The process also causes the hide to become more flexible. The vegetable-tanned hide is not very flexible. It is used for luggage, furniture, footwear, belts, and other clothing accessories.