M.D. Teli*, Javed Sheikh and Monika Mali

Department of Fibres and Textile Processing Technology,

Institute of Chemical Technology

Matunga (E), Mumbai-400019, India

mdt9pub@gmail.com, javed_uict@yahoo.co.in

Abstract

Wool is an important protein fibre for application as textiles. However the lack of antibacterial properties of such protein containing fibre is held as a severe limitation for its applications in hygienic textiles and the need to make it antibacterial is quite intense. Green tea is considered to be a good antioxidant and can act as natural dye for dyeing of wool.

In the current study, dye was extracted from green tea using aqueous extraction method. Wool fabrics were dyed using green tea extract using metal mordants and evaluated for dyeing properties like colour values and fastness as well as antibacterial properties. The dyed wool fabric displayed satisfactory colour values and good fastness properties as well as antibacterial properties against both gram positive and gram negative bacteria. The results clearly indicated the advantages of using such dye with metal mordants both in case of obtaining dyeing and antibacterial functionality to wool.

Keywords-Green tea; Natural dyeing; Antibacterial properties

INTRODUCTION

Textiles, especially those made of natural fibers, are an excellent medium for the growth of microorganisms when the basic requirements for their growth such as nutrients, moisture, oxygen, and appropriate temperature are present. The large surface area and ability to retain moisture of textiles also assist the growth of microorganisms on the fabric [1] which intern results in inflicting a range of unwanted effects not only on the textile itself but also on the wearer. These effects include the generation of unpleasant odor, stains, discoloration in the fabric, a reduction in the tensile strength of the fabric and an increased likelihood of contamination [2]. In the last few decades, with the increase in new antimicrobial fibre technologies and the growing awareness about cleaner surroundings and healthy lifestyle, a range of textile products based on synthetic antimicrobial agents such as triclosan, metal and their salts, organometallics, phenols and quaternary ammonium compounds, have been developed and quite a few are also available commercially [3]. Even though the excellent antimicrobials are available, their effect on ecology is always a question. Under this backdrop some of the natural dyes reported to possess antimicrobial properties, attract the attention of the researchers in this field.

On the other hand the development of synthetic dyes taken place at the beginning of the twentieth century has come a long way and led to a more complete level of quality and more reproducible techniques of application. Due to wide applications on variety of fibres, and the economies of scale, considerable reduction in the dyestuff costs per kg of dyed goods has been achieved [4] making their application economical. But, during the last two decades, the use of synthetic dyes based on red listed chemicals is gradually receding due to an increased environmental awareness and harmful effects because of either toxic degraded products or their non-biodegradable nature. In addition to above, some serious health hazards like allergenicity and carcinogenecity are associated with the synthetic dyes. As a result, a ban has been imposed all over the world including European Economic Community (EEC), Germany, USA and India on the use of some synthetic dyes like azo dyes which finally triggered active research and development to revive world heritage and traditional wisdom of employing safer natural dyes [5]. Consumers nowadays are becoming more and more concerned about environmental issues and hence are demanding natural products incorporating natural ingredient. Thus natural dyes are gaining increasing importance as they are obtained from renewable resources and they present practically no health hazards and some of them sometimes act as a health care products too [6].

However, natural dyes in general, with few expectations are non-substantive and hence must be used in conjunction with mordants. Mordant is a chemical, which can fix itself on the fibre and also combines with the dyestuff. The challenge before the natural dyers in application of natural colour is necessity to us metallic mordants which themselves are pollutant and harmful. Due to the environmental hazard caused by metallic mordant while dyeing of textile fabric, manufacturer’ have to find out safe natural mordant for application of natural dyes.

There are many beneficial aspects of green tea to human such as it is anti-carcinogenic anti-aggregant,anti-allergic,anti-bacterial,anti-mutagenic,and anti-oxidant. Besides these beneficial aspects,it has been reported that green tea ingredients,especially polyphenolic families ,have some UV protection property both in vivo and in topical application[7].

The tannins in green tea interact with proteins and are astringent and also have antioxidant activity. One of the polyphenols in green tea-epigallocatechin galate(EGCC)is thought to be more powerful than vitamin E for neutralizing free radicals.It contains caffeine as well as triterpene saponins,carotenoids and non-protein amino acids(thyeanine,2-amino-6-ethyamidoadipinic acid). Green tea is often included in anti-ageing skincare products for the antioxidant properties contained in the herb [8-10].

Tannins are astringent and antimicrobial in nature and metal salts are also known for such properties. Hence combination of metal mordants and green tean as a natural dye can impart antibacterial functionality to wool apart from the colour. The application of green tea using metal mordants hence can act in dual way of natural coloration and antibacterial finishing for wool. In the current work, the simultaneous dyeing and antibacterial finishing of wool fabric has been carried out using metal mordants and green tea. The colour values, fastness properties and antibacterial efficacy of the dyed material were evaluated.

MATERIALS

Wool fabric was purchased from the market. Green tea was purchased from the tea factory (Ooty, Tamilnadu). All chemicals used were of laboratory grade.

METHODS

Preparation of mordant

The 1% stock solution of metal mordants (alum and CuSO4) was made by dissolving 1 gm of mordant powder in 100 ml water. The stock solutions were used for mordanting of wool fabric as per the concentration required (on the weight of fabric).

Extraction of dye

The 1% stock solution of the green tea was prepared by boiling 10 g of dry tea powder in 1000 ml water for 1 h. The extract was filtered and made to 1000 ml and used for dyeing.

Mordanting and dyeing of wool

The mordanting of wool fabric was carried out in rota dyer (Rota Dyer machine, Rossari® Labtech, Mumbai) keeping the liquor to material ratio of 30:1.The fabrics were introduced into the mordant solution at room temperature and slowly the temperature was raised to 95oC. The mordanting was continued at this temperature for 30 min. After mordanting, the fabric was squeezed and dyed using green tea extract as a dye. The mordanted fabrics were introduced in dyebath and dyeing was continued at 900C for 1h. After dyeing, the fabrics were squeezed and washed with cold water.

Colour value by reflectance method

The dyed samples were evaluated for the depth of colour by reflectance method using 10 degree observer and Spectraflash SF 300 (Datacolor International, U.S.A.) equipped with reflectance accessories. The K/S values were determined using expression;

(1-R) 2

K/S =

2R

where, R is the reflectance at complete opacity, K is the Absorption coefficient & S is the Scattering coefficient

Dyed fabrics were simultaneously evaluated in terms of CIELAB colour space (L*, a* and b*) values using the Spectraflash SF300.

In general, the higher the K/S value, the higher the depth of the colour on the fabric. L* corresponding to the brightness (100= white, 0= black), a* to the red–green coordinate (+ve= red, -ve =green) and b* to the yellow–blue coordinate (+ve =yellow, -ve =blue). As a whole, a combination of all these enables one to understand the tonal variations.

Washing fastness

Evaluation of colour fastness to washing was carried out using ISO II methods [11].

Rubbing fastness

Evaluation of colour fastness to rubbing (dry and wet) was carried out using “crock-meter” with 10 strokes of rubbing.

Light fastness

Dyed fabric was tested for colourfastness to light according to ISO 105/B02 [12]. The light fastness was estimated using artificial illumination with Xenon arc light source, Q-Sun Xenon Testing Chamber with black standard temperature 65 0C with relative humidity of the air in the testing chamber as 40% and daylight filter, wavelength, k= 420 nm. The samples were compared with the standard scale of blue wool ratings.

Determination of antimicrobial activities of dyed fabrics

The antibacterial activity of the dyed fabrics was estimated by AATCC Test Method 100-2004 [13]. The reduction in number of bacterial colonies formed with respect to the untreated control sample was estimated by using following equation,

100 (B – A)

R =

B

where,

R = reduction in bacterial count (%),

A = the number of bacterial colonies recovered from the inoculated treated test specimen swatches in the jar incubated for 24 hr contact period;

B = the number of bacterial colonies recovered from the inoculated untreated control test specimen swatches in the jar immediately after inoculation (at “0” contact time).

RESULTS AND DISCUSSION

Optimization of mordant and dye concentrations

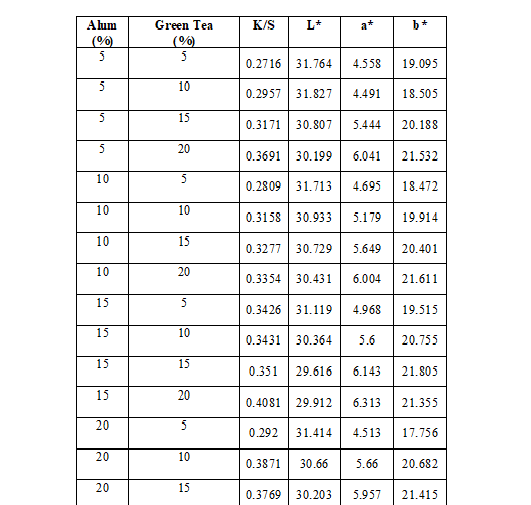

The dyeing of wool using metal mordant alum and CuSO4 was attempted and results are summarized in Tables 1 and 2.

The wool fabrics were dyed using different mordant and dye concentrations. At the constant dye concentration, the increase in concentration of alum resulted in increase in colour values of wool till 20%. Hence 20% alum concentration was taken as an optimum concentration. For a constant alum concentration, K/S values were found to be increasing with green tea dye concentration from 5% to 20%. The colour value thus obtained, in the case of natural dyes is a combined contribution of the effect of mordant and the dye. Hence the K/S was improved with mordant and dye concentration initially till the equilibrium was reached. The increase in concentrations of either mordant or dye beyond optimum concentrations did not significantly contribute in the improvement of the depth of dyeing which is reflected in K/S values. Hence 20% dye concentration was taken as optimum.

Table 1:

Effect of alum and Green tea concentration on colour values of Wool fabrics

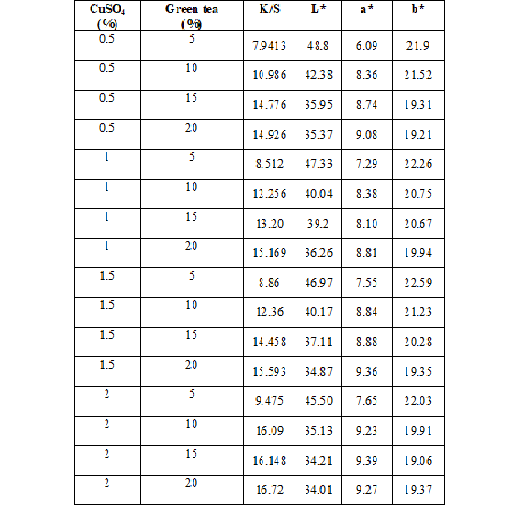

Results in Table 2 clearly indicate the increase in K/S values with increasing CuSO4 concentrations from 0.5 to 2%. For a constant mordant concentration, K/S values increased with increasing dye concentration. The higher K/S values resulted using higher mordant and dye concentration. However the colour values got almost levelled- off for 2% mordant and 10% green tea concentration (refer Table 2). The colour values obtained using CuSO4 as a mordant were distinctly higher than those compared with that of alum as a mordant. However the different shades were obtained using different mordants and dye combinations enabling one to have wider choice of hues from the gamut of different shades obtained in case of natural dyeing.

Table 2:

Effect of CuSO4 and Green tea concentration on colour values of Wool fabric

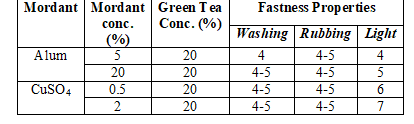

The fastness properties which are the indication of resistance of dye to removal in presence of various agencies are evaluated and results are summarized in Table 3. The results in Table 3 indicate the good to excellent fastness properties of the dyeings obtained using various mordants.

Table 3: Fastness properties of the dyed wool fabrics

The washing fastnesses obtained varied in the range of very good to excellent grade. The rubbing fastness was also found to be of the grade very good to excellent. Light fastness seemed to be dependent on the colour values and was distinctly higher in case of CuSO4 as a mordant. The light fastness properties were improved for mordant concentration 20% as compared to that for 5%, for both the mordants, as a result of increased colour values.

A. Antibacterial activity of green tea dyed wool fabrics

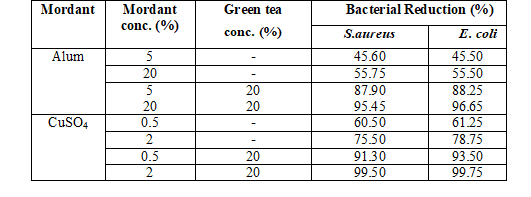

The quantitative antibacterial assessment was made using AATCC-100(2004) test method and the results are presented in

Table 4

Effect of mordant type and concentration on antibacterial properties of dyed wool

In order to confirm the antibacterial activity of green tea as a dye, the antibacterial activity of only mordanted and mordanted-dyed sample was evaluated. The antibacterial activity of only mordanted sample was lower, in both the mordants, than that of mordanted-dyed wool fabrics which indicates the positive contribution of green tea towards antibacterial activity. The dyed fabrics which were earlier mordanted showed excellent antibacterial activity against both S.aureus and E.coli bacteria. The antibacterial activity improved for higher mordant concentration in case of both the mordants.

CONCLUSION

Ecofriendly dyeing and antibacterial finishing of wool fabric was successfully carried out using metal mordants and green tea as a dye. The dyed product displayed good colour strength, although it was distinctly lower for alum than those obtained using CuSO4 as a mordant. The dyed wool also displayed superior fastness properties which were distinctly better for CuSO4 mordant. The natural mordanted-dyed samples displayed broad spectrum and efficient antibacterial activity. The role of green tea in imparting antibacterial functionality was also confirmed through the current research. The concept of natural dyeing of wool fabric using green tea as a dye and metal mordants with an aim to produce gamut of shades and the same time impart antibacterial property seems to be indeed promising one.

REFERENCES

[1 ] Su, W., Wei, S., Hu, S. and Tang, J., Journal of the Textile Institute, 102, 150-156 (2011).

[2] Gao, Y. and Cranston, R., Textile Research Journal, 78, 60-72 (2008).

[3] Joshi, M., Ali, S. W., Purwar, R. and Rajendran, S., Indian Journal of Fibre and Textile Research, 34, 295-304 (2009).

[4] Bechtold, T., Turcanu, A., Ganglberger, E., Geissler, S., Journal of Cleaner Production, 11, 499–509 (2003).

[5] Kumary, J. K. and Sinha, A.K., Natural Product Letters, 18(1), 59–84 (2004).

[6] Prabhu, K.H., Teli, M.D. and Waghmare, N., Fibers and Polymers, 12(6), 753-759(2011).

[7] Anderson, B., Creative Spinning, Weaving and Plant Dyeing, Angus and Robinson, 24‐28 (1971).

[8]https://www.scribd.com/doc/59595926/Dyeing-of-Wool-Fabric-With-Dye-Extracted-From-tea.

[9] https://resources.metapress.com/pdf preview.axd?code=size=largest1lw40162x6837g68&

[10] https://www.fibre2fashion.com/industry-article/19/1875/green-is-good-organic-clothing-and-herbal-dyeing1.asp

[11] Trotmann, E.R.. Dyeing and Chemical Technology of Textile Fibres, England: Charles Griffin and Company ltd, 1984.

[12] ISO technical manual, Geneva, Switzerland, 2006.

[13] American Association of Textile Chemists and Colorists. AATCC Technical Manual 2007, 76, Research Triangle Park, NC: AATCC.