*The Yarn Bazaar* team in association with *Standon Consulting* presents a series of small advisory notes made through advice of textile experts on ‘how to restart safely and systematically the various departments in your textile unit’.

We felt that these could be of help and guidance to everyone.

As an extension, they are also providing FREE consultation and guidance on call for a period of one week to anyone who has queries or seeks assistance.

This was prepared with Mr. Manoj Srivastava, Plant head BRFL Tarapur

Preventive Steps to be taken:

Important Safety Note :

DUE TO RUBBER GETTING BRITTLE DURING PROLONGED SHUT DOWN THERE IS A LIKELYHOOD OF THE LOOM CONNECTION FELXIBLE PIPES BURSTING WHEN PRESSURIZED. MAKE SURE THAT PEOPLE ARE CLEAR OF THE PIPE AREA AND PRESSURE IS INTRODUCED ONLY GRADUALLY. SEE POINT 3 BELOW.

Suggested Best Practice:

1. Do not let weavers / Gaitors start looms on their own or simultaneously.

2. The trained staff should form a team or at best be split into two teams with qualified personal heading each

3. They should work on one machine at a time and move to next one only once the first machine has settled down in operation at least 15 minutes.

Air line

1. Disconnect air pipe connection to machine.

2. First drain all compressed air in open in all lines till all water/moisture or any iron particles are drained out before entering into the machine.

3. Since lock down period is quite long there is every possibility of hardening of main rubber pipe and subsequently getting punctured so keep some air pipe and jubilee clamps in hand to replace if any accident occurs.

4. Check all air valves and air pipes and test them manually. Replace them if found anything defective.

5. Clean Air filter and remove all dirt and water droplet.

Clean the machine thoroughly with compressed air.

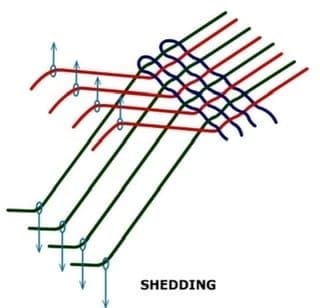

Shedding

1. Clean and filter all oil in Cam Box or Dobby and top up the oil if level is found less

2. Clean oil filter

3. Re Grease complete system and make sure that all old grease is out from the system

4. Clean side support of the frames and oil them and make sure not to put excess oil as it will create more problem,

5. Release the warp tension on beam and do the Zero Setting again.

6. Check all Leno devices manually and readjust their tensions and timings.

7. Follow manufacturers instruction for restart.

Picking

1. Check all nozzles and pipes and recalibrate all the valves.

2. Check all connections of Filling Detectors etc.

Beatup

1. Clean oil filter, check main oil level and top up if found less.

2. Clean all old grease with cloth and re grease all points

3. In case of centralize or piped greasing points first remove all old grease as in most of the cases if it is dried up please take care as it may lead to puncture the pipes while re greasing.

Electrical

1. Check panels for animal presence

2. Clean the panels with air and blower properly

3. Remove Panel Moisture with Hot Air Blower

4. Check all Power and Control Cables manually for any damages

5. Check all tube lights and their connections manually as they are the most dangerous points for fire.

6. Check all Taped joints and Re Tape them to prevent any spark

7. Check main power supply voltage and Earthing

8. After starting the machines take main load in all phases on individual loom.

2. Clean the panels with air and blower properly

3. Remove Panel Moisture with Hot Air Blower

4. Check all Power and Control Cables manually for any damages

5. Check all tube lights and their connections manually as they are the most dangerous points for fire.

6. Check all Taped joints and Re Tape them to prevent any spark

7. Check main power supply voltage and Earthing

8. After starting the machines take main load in all phases on individual loom.

General

1. After checking the entire points start loom one by one and start next loom at least after 15 minutes of the previous loom so that in case of any accident it can be taken care of.2. Do not change any setting of the looms as during whole lock down period in most of case warp sheet was under tension so after few meters of weaving things will become normal.

3. Start the looms at least one hour after the H plant working gets established and department is in conditioned environment. This one-hour grace period will help the warp sheet to regain its weaving strength and also it will clean the dust and dirt in the environment.

4. Most Important after running the department for 24 hrs. again clean the main air line by opening all vent valves and remove all moisture and the rust particles settled in line. Also, re clean all the filters in line and on all the looms individually.

5. REFER TO MANUFACTURERS INSTRUCTION AS MAY BE ISSUED BY THEM FOR SAFE START UP.

Mr. Sharad Tandon – Standon Consulting

+91 93222 60941

standon@standonconsulting.com

The Yarn Bazaar

www.theyarnbazaar.com

+91 93269 61542

partner@theyarnbazaar.com