Ali1 , Mukesh Kumar2, S. Barhanpurkar3, A. Joshi4, T. Malik5

1 & 2 Uttar Pradesh Textile Institute Kanpur

3,4&5 Shri Vaishnav Institute Of Technology & Science Indore

ABSTRACT

As a famous Scandinavian economist said, ―It is very dangerous to make predictions, particularly about the future!‖. Whenever we talk of the term futuristic, it deals with expressing the vision of future. With advancement of science & technology, products beyond our present perception can be produced. In the concerned paper we have cited innovations in fibers being called as bio-degradable and High Performance Fiber & High Functional Fiber. With the invent of Hi- Performance fiber and bio degradable fibers the spectrum of application of fibers High Functional Fiber and textile materials were substantially widened. In the paper there is also some light thrown on some newer multimaterial fibers and some natural fibres with recent futuristic developments.

Over the last 5 years the global fibre market has moved further into a global commodity market. This change is redefining and accelerating global trade patterns at all levels of the high valve chain. The development of special fibres is the consequence of merging fundamental scientific and technical knowledge, as there is a quest for high performance fibres. Thus, constant and continued endeavors of fibre scientists jointly ventured with material technologies had made dreams into reality. These special fibres totally provide the potential for providing new technology. Overall world textiles, challenging a continued growth of hi-tech fibres in various fields. These fibres have high tenacity, high strength to weight ratio which are the prerequisites characteristics of industrial textiles. These find applications in every walk of life including Space, Ocean, composites, aircrafts , defense, automobile and many more. Our present paper deals with these special fibres and explores the wealth of their properties and application.

In the concerned paper we have studied some high functional fibres and high performance fibres like ceramic, melamine, microfiber having applications in thermal industries & water repellent properties. We have also discussed some biodegradable fibres like alginate, collagen, bacteria cellulose used in microsurgery, artificial tissues and wound dressing. There is also study made on some multimaterial fibres having applications in field not even thought of in present , like using fibres in camera lenses. Also we have applied some futuristic study on natural fibre like cotton, by putting a spark on it, we found its application in monitoring biological functions such as heart beat, perspiration or insulin levels.

INTRODUCTION

Up to this time, two types of fibers have been available to human society, natural fibers that have existed for 4000 years and synthetic fibers. Artificial silk invented was a human dream. Then nylon introduced was finer than spider‘s thread, stronger than steel and more elegant than silk. Today synthetic fibers are not a mere alternative to natural fibers but are new materials of high functionality and high performance, which play a key role in the field of high technology. These new materials can be designed and produced according to nature of their utilization. Synthetic fibers are made to replace natural fibers and to some extent it is succeeded. High performance fibers are developed now-a-days fibers of high modulus and high strength can now be produced from synthetic polymers of light weight and are widely employed in space. Due to limitations of natural fibers, synthetic fibers are developed and now-a-days developments are done in the fibers to achieve desired properties. The need for ultra light fibers of high strength is increasing as high technology responds to changes in the social environment so; developments are going on in the synthetic fibers. In future decades, metals are expected to be replaced by newly developed synthetic fibers, which can be superior to metal with respect to their strength and modulus. In all the fields, there is wide application of fibers. Kevlar Application cables, rope making, fiber reinforcement, Industrial paper, friction products, thermo chromic fiber changes color as per environmental conditions. Solar – X Stores solar energy BEMBERG Micro-porous membrane Diagnosis and treatment of AIDS (BMM).

As a famous Scandinavian economist said, ―It is very dangerous to make predictions, particularly about the future!‖ Whenever we talk of the term futuristic, it deals with expressing the vision of future. With advancement of science & technology, products beyond our present perception can be produced. In the concerned paper we have cited innovations in fibers being called as bio-degradable and High Performance Fiber & High Functional Fiber. With the invent of Hi- Performance fiber and bio degradable fibers the spectrum of application of fibers High Functional Fiber and textile materials were substantially widened. In the paper there is also some light thrown on some newer multimaterial fibers and some natural fibres with recent futuristic developments.

Over the last 5 years the global fibre market has moved further into a global commodity market. This change is redefining and accelerating global trade patterns at all levels of the high valve chain. The development of special fibres is the consequence of merging fundamental scientific and technical knowledge, as there is a quest for high performance fibres. Thus, constant and continued endeavors of fibre scientists jointly ventured with material technologies had made dreams into reality. These special fibres totally provide the potential for providing new technology. Overall world textiles, challenging a continued growth of hi-tech fibres in various fields. These fibres have high tenacity, high strength to weight ratio which are the prerequisites characteristics of industrial textiles. These find applications in every walk of life including Space, Ocean, composites, aircrafts, defense, automobile and many more. Our present paper deals with these special fibres and explores the wealth of their properties and application.

TYPES OF FUTURISTIC FIBRES

In the concerned paper we have cited three categories of futuristic fibres, Namely:

- High Performance Fibres & High Functional Fibres.

- Bio-Degradable Fibres.

- Multimaterial Fibres.

HIGH PERFORMANCE & HIGH FUNCTIONAL FIBRES

A.) High Performance Fibres:

High-performance fibers, used in fabric applications ranging from bulletproof vests to trampolines, must have a sufficient number of chemical and physical bonds for transferring the stress along the fiber. To limit their deformation, the fibers should possess high stiffness and strength. Stiffness is brought about by the degree to which the chemical bonds are aligned along the fiber axis. In fiber-reinforced composites, the fibers are the load-bearing element in the structure, and they must adhere well to the matrix material. An ideal reinforcing fiber must have high tensile and compressive moduli, high tensile and compressive strength, high damage tolerance, low specific weight, good adhesion to the matrix materials, and good temperature resistance.

High performance fibres refer to high strength, high modulus, and wear resistant deformation resistant and high temperature resistant fibres. The high performance fibre industry is targeting those areas which are the domain of glass, polyester and nylon fibre reinforcements. High performance fibres are being increasingly used for a wide range of applications including goetextiles and geomembranes and for construction and civil engineering projects as well as in specialist fibres within composite materials where their ability to fulfil demanding roles makes them an effective choice for the engineer and materials scientist. Major applications for the high performance fibres are transportation, aerospace, protective clothing, marine (ropes and sails), hostile thermal and chemical environments (replacement for asbestos) and leisure activities industries (golf clubs and tennis rackets).

B.) High Functional Fibres:

The continuing advances in the field of sports, protective textiles, medical and hygiene requirements, etc, existing fibers is being modified and new fibers are being developed to meet specific and stringent requirements of the technical applications. There is a regular demand for the production of functional and specialty fibres. Therefore the fiber and polymer technologists have been continuously innovating new fibres to develop high performance and functional textiles. The term high functional fibers can interpreted in a number of different ways. One interpretation is that, it is a fibre with high tenacity, high modulus and less weight for the application of filtration and sports textiles. In the case of medical and hygiene products, it should free from toxic and biodegradable. For protective textiles, fibers should be high resistance to corrosive chemicals and high resistance to elevated temperatures, flames and very high hydrophilic. In the next millennium, textiles will not just be an extension on simple alternatives to natural or synthetic fibres, they will provide superior functionalities and enter into more novel and unexpected applications. New millennium fibres describe and identify the scope of high – tech fibres.

VARIOUS KIND OF HIGH PERFORMANCE & HIGH FUNCTIONAL FIBRES:

Some of the successful high performance & high functional fibres are discussed below on basis of their present prospectus & future application.

1.) MELAMINE

Melamine fibre is a synthetic polymer composed of 50% by weight of a cross-linked melamine polymer. Due to the cross linked structure, and low thermal conductivity of the melamine resin, these fibres posses high stability. It displays inherent thermal resistance and heat blocking abilities in direct flame applications. Melamine fibre has recently entered the high temperature fibre market, one of the newest fibres, and has made a rapid impact. Melamine fibre is an advanced synthetic fibre having superior heat and flame resistance with decomposition temperature above 350°C. Melamine fibre is designed to enhance commodity fibres and synergistic high-temperature fibres to deliver cost-effective, engineered heat insulating and flame-resistant solutions, the fibre is white and dyeable, can be processed on standard textile manufacturing equipment for the production of woven, knitted, and nonwoven fabrics.

Production of Melamine fibre

The production process Melamine fibre is proprietary. It is based on a unique Melamine chemistry that results in a cross-linked, non-thermoplastic polymer of Melamine units joined by methylene and dimethylene ether linkages. In the polymerization reaction, methylol derivatives of Melamine react with each other to form a three-dimensional structure. This network structure of Melamine fibre produces unique fibres with excellent inherent characteristics for fire protection, heat stability and low flammability – that is also durable and resistant to chemical sand ultraviolet light.

Fibre properties

Melamine fibre is a cost effective heat resistant fibre with a 400°F (200°C) continuous operating temperature. Melamine fibres are flame resistant, have outstanding heat/dimensional stability, and are self-extinguishing. Below are some important characteristics of Melamine fibre:

- Inherent, non-toxic protection

- Highly insulating

- Attractive finish

- Durable and protective

- Cool and breathable

Uses and applications

Apparel made with Melamine provides superior comfort, softness and breathability while protecting people who work in hazardous environments. Melamine is suitable for competitive and compliant protective apparel solutions those are well-suited to industrial, military and fire service professions. In the event of a fire, protective apparel must resist flame exposure and protect the wearer. Fabrics made with Melamine retain flexibility and dimensional stability when exposed to direct flame, ensuring that protective garments will not break open or shrink away during fire exposure. Fabrics made with Melamine add insulation and protection in technical apparel. Following are the major application of Melamine fibre in apparel:

- Fire fighter turnout gear, including gloves and hoods

- Military and law-enforcement protective gear

- Industrial garments and protective work wear.

- Racing apparel Apart from apparel, Melamine is also used for below application in industry:

- Mattresses, home furnishings/nonwovens

- Speciality flame resistant papers

- Electrical papers

- Transmission/friction papers

- Filtration media

- Engineered materials/Short-fibre composites

- Adhesives/Fillers

- Tire sealants

- Truck/Rail brakes

- Fire blocking fabrics: Aircraft seating, fire blockers for upholstered furniture in high-risk occupancies

- Filter media: High capacity, high efficiency, high temperature bag house air filters.

2.) CERAMIC FIBRES:

Continuous fibers of metal oxides or refractory oxides which are resistant to high temperatures (2000-3000°F). This class of fibers includes alumina, beryllia, magnesia, thoria, zirconia, silicon carbide, quartz and high silica reinforcements. Although glass is also a ceramic material, glass fibers are not generally included. Ceramic fibers are produced by chemical vapor deposition, melt drawing, spinning and extrusion. Their main advantage is high strength and modulus. Ceramic fibers are also used as refractory fibers in uses over 1000°C. Ceramic fibers also mostly used for thermal insulation at high temperatures and to make special composites.

APPLICATIONS OF CERAMIC FIBRES:

Ceramic Fiber is an aluminosilicate based refractory fiber, white and odorless. It resists temperature as high as 2300º F. The fibre products are lightweight with very low thermal conductivity. They provide excellent insulation at high temperature, and resist corrosive chemicals such as commonly used acids and alkalis. These products are excellent substitutes for asbestos products in many insulation and sealing applications.

VARIOUS PRODUCTS RANGE ARE:

- Ceramic Fiber Cloth

The cloth is reinforced with fiberglass filament, and optional Inconel/alloy steel wire. Ceramic fiber textiles (cloth, tape and rope) contain a certain amount of binder material which is normally burned at lower temperature and does not affect the insulation property.

Typical applications of ceramic fiber cloth include: expansion joints, safety blankets, curtains, welding blankets, protective and insulating covers, shields, gaskets, cable or pipe wrapping, etc. It has been widely used in welding, foundry works, aluminum and steel mills, boiler insulation and seal, shipyards, refineries, power plants and chemical plants.

- Ceramic Fiber Tape

Typical applications of ceramic fiber tape include: protective and insulating covers or shields, cable or pipe wrapping, expansion joints, high temperature seals or gaskets. The product has been widely used in welding, foundry works, aluminum and steel mills, boiler insulation and seal, exhaust systems, shipyards, refineries, power plants, and chemical plants.

- Ceramic Fiber Rope

The ceramic fibre rope is present in 3 forms, Twisted Rope, Round Braid & Square Braid.

Common applications include door seals or caulking for ovens, furnaces and boilers, expansion joints, cable or pipe wrapping, high temperature seals or gaskets. These products have been widely used in welding, foundry works, aluminum and steel mills, boiler insulation and seal, exhaust systems, shipyards, refineries, power plants and chemical plants. They are also used as the core in tadpole gaskets. The three different styles are designed to fit different application needs: twisted rope is a soft rope, while square and round braid are more dense and solid.

- Ceramic Fiber Blanket

Blanket resists temperature as high as 2300º. This material is lightweight and has very low thermal conductivity, excellent handling strength, low heat storage, thermal shock resistance and corrosion resistance (commonly used acid and alkali). It also provides excellent sound absorption and excellent fire protection.

Typical Applications of Blankets

- Repair, insulation and linings for furnaces, kilns, generators, reformers, boilers, etc

- Insulation for steam and gas turbines, and other high temperature equipment

- Insulation for nuclear applications and power plants

- High-temperature pipe insulation, casting mold insulation, etc.

- High-temperature seals and gasketing, furnace door seals, expansion joint seals

- Fire protective insulation or linings

- High-temperature filtration

Power fibers that store solar energy

Heat regenerating fibers are produced from ceramic composites by applying heat insulation processing technology, which utilizes the far infrared radiation effect of ceramic. When heated ceramics radiate far infra-red radiation, which penetrates into the material and heats it homogeneously by activating molecular motion. Zirconium, magnesium oxide or iron oxide can be blended into synthetic fibers, because these materials radiate Ca.60 mW far infrared of wavelengths 8-14 um at a body temperature of 36oC. These heat reradiating fibers are used for sports wear, bead-sheets, bed-cover materials, etc.

- SUPERABSORBENT FIBRES:

In last few years, super absorbents in fiber from have become a commercial reality. The recent commercial availability of super absorbent fibres has spurred an enormous amount of development activity in many market applications including telecommunications, packaging, horticulture, electronics and disposable hygiene products. Most recently the potential to benefit from their outstanding properties in a wide range of medical products have been recognized. The product is marketed as ‘OASIS’. The product is based upon similar polymer chemistry to that for powders that is a cross-linked copolymer of acrylic acid. The advantages that fiber offers compared to fibers are due to their physical form, or dimensions, rather than their chemical nature. Whilst they do absorb fluids to a similar level as powders, they do, however, do it faster. This is due to the small diameter of the fibers, which is about 30 microns, which gives a very high surface area for contact with the liquid. Also the fiber surface is not smooth. It has a crenulated structure with longitudinal grooves. These are believed to be beneficial in transporting moisture along the surface. The lubricant has also been selected to enhance this wetting effect and results in a very high rate of moisture absorption. Typically the fiber will absorb 95% of its ultimate capacity in 15 sec.

Properties

1.) The following features that may be required for use in medical product can be build up into nonwoven containing super absorbent fibers:

- High absorbency, even under pressure

- Softness and flexibility

- Low migration of the super absorbent when dry and wet

- High rate of Iiquid up-take

- Fabric dispersion when wet

2.) This feature of fibers not to migrate is a very important advantage. It allows the Super absorbent to be blended at high levels into an open structure without it falling out or its distribution in the fabric changing during storage, transport and use. This natural advantage gives more flexibility as to where the absorbent can be located.

3.) A unique advantage of a super absorbent in fiber form is that staple yarns can be spun in blends with other fibers. Yarns can be produced on warp woollen, DREF and semi worsted spinning systems but warp spinning is the preferred route as the lack of twist provides a yarn free to swell easily. It is possible to blend Oasis in these yarns with both natural and synthetics fibers.

Application in Medical Products

- Disposable Incontinence Products

High levels of superabsorbent fiber can be incorporated into absorbent cores allowing the constructing of thin products with high absorbency. Wipes and absorbed pads: Addition of oasis to pads and wipes to improve their ability to rapidly immobilize large amounts of blood and other aqueous spillages in operating theatre, Analytical laboratory or general hospital use.

- Disposal containers

Superabsorbent non-woven fabrics can be used as a lining for containers designed for the disposal of items contaminated with hazardous fluids to prevent leakage.

- Drapes

In surgical gowns, oasis can be incorporated around the arm and neck cuffs to prevent blood ingress.

- Wound care

Oasis can be included within secondary wound care products to provide additional capacity to absorb wound exudates. This helps to decreases the frequency of dressing changes.

- Ostomy bags

Oasis can be incorporated into ostomy and colostomy products and waste management devices to quickly solidify body fluids to improve ease of disposal.

- Miscellaneous products

A number of other applications in the medical field are currently being evaluated including:

- Headbands for sweat control by surgeons,

- Diagnostic testing,

- Hand sticks,

- Dental pads.

- VECTRAN FIBRE

Production techniques

Vectran fibre liquid crystal aromatic polyester noted for its thermal and chemical stability, moisture resistance, high strength and modulus, to enhance the performance of many of our products. Among other applications, we have woven Vectran to strengthen fabric for use in blimps, lighter-than-air vehicles; Vectran is the only commercially available melt spun liquid crystal polymer (LCP) fiber in the world. Vectran HT performs well in applications where dimensional stability and durability are required in both high and low temperature extremes. Vectran is a manufactured fibre, spun from a liquid crystal polymer created by Celanese Acetate LLC, chemically it is an aromatic polyester produced by the poly-condensation of 4-hydroxybenzoic acid and 6-hydroxynaphthalene-2-carboxylic acid.

Characteristics

- High strength and modulus

- Excellent creep resistance

- High abrasion resistance

- High impact resistance

- Minimal moisture absorption

- Excellent chemical resistance

- High dielectric strength

- Outstanding cut resistance

- Excellent flex/fold characteristics

- Low coefficient of thermal expansion (CTE)

- Outstanding vibration damping characteristics

- Excellent property retention at high/low temperatures

Applications

- Ropes and cable

- Aerospace

- Military

- Industrial electromechanical and inflatable structures

- Rubber reinforcement industry and diaphragm construction

- Inflatable wind turbine generators

- High-performance sailcloth

- Recreation and leisure

- Sports goods

- MILK WEED FIBRE

Origin

Milkweed fibres are new fibres which are used as a filling material in jackets, pillows etc., it is a very shiny, slippery fibre with poor dinging ability. Milkweed a perennial plant that can adapt to adverse soil conditions is being developed as an alternative crop. Milkweed belongs to the ‗genous Asclepias‘. The genus Asclepias contains over a hundred species of mainly perennial herbs growing in temperature and tropical regions.

The four species of milkweed are

- Incartana swamp milkweed

- Speciosa showy milkweed

- Syriaca common milkweed

- Tuberose pleurisy root

Properties of Milkweed Fibre

- It is a very shiny, slippery fibre with poor clinging ability.

- It itself cannot be spun but can be mixed with other fibres.

- It has very good customer‘s property.

- It is fire-resistant due to the high silica content of the fibre.

- It has poor dye acceptation capacity

- It has very low moisture absorbing Tendency.

Applications

- It is used as the filling material in jackets, comforters, pillows etc.

- Can be used as a report substitute for stuffing soft toys etc.

- Also used for making candle wicks

- Difficult to spin on its own, it can be mixed with other fibres to make cloth.

- Contains latex which can be made into a good quality rubber

- Sometime it is used to make paper

- Stalk fibre used for cord making

- This fibre also makes carpets.

- The stem portions are used for making papers.

- MICROFIBRE

Microfiber commonly refers to any fiber with strand less than 1 denier. Textile synthetic microfibers such as polyester microfibers have a diameter of about 10 microns or less. While most microfibers are of synthetic origin, asbestos can be considered as natural mineral microfibers since the fibers width is less than 1 micron. Dr. Miyoshi Okamoto has developed synthetic microfibers in Japan in the early 1970. Different polymers though can be used to produce microfibers, polyester and nylon are the most employed and are often mixed together to obtain specific properties.

Properties:

A microfiber’s diameter often measures half of a silk fiber and allows producing very lightweight fabrics with excellent draping qualities, wearing comfort and luxurious appearance. When woven appropriately microfiber fabrics have even more properties: good isolation, impermeability, breathing ability, wrinkle-resistance, stain-resistance, and easy wash ability.

Applications

Microfibers used in tablecloths, furniture, and car interiors are designed to repel liquids and consequently are difficult to stain. Microfiber tablecloths will bead liquids until they are removed; they are sometimes advertised showing red wine on a white tablecloth that wipes clean with a paper towel. This, and the ability to mimic suede economically, are the most common selling points for microfiber upholstery fabrics (e.g. for couches). Microfibers are used in towels, especially those to be used at swimming pools, as even a small towel dries the body quickly. They dry quickly and are less prone to become stale if not dried immediately than cotton towels. Microfiber towels paradoxically need to be soaked in water (and pressed) before use, as otherwise they would repel water as microfiber tablecloths do.

- LOTUS FIBRE

The lotus fibre came into existence after exploring several ways to obtain the highly hydrophobic ―lotus‖ fabric. Water and soil repellency has been one of the major targets for fiber and textile scientists and manufacturers for centuries. Combinations of new materials for fiber production with a variety of surface treatments have been developed to reach the condition of limited wettability. Nevertheless, additional efforts are needed to create fiber and textile materials with ideal repelling properties. Nature has already developed an elegant approach that combines chemistry and physics to create superrepellant surfaces. Lotus leaves are unusually water-repellent and keep themselves spotless, since countless miniature protrusions, coated with water-repellant hydrophobic substance, cover their surface. Water cannot spread out on the leaves and it rolls around as droplets, removing grime and soil as it moves. The lotus effect is based on the surface roughness caused by different microstructures combined with hydrophobic properties of the wax covering the leave surface. The surface roughness is the key prerequisite for the lotus effect. The contact angle of water is large and the leaves are covered by wax like substance.

For the fabrication of the lotus fibers two major requirements are to be fulfilled:

- The fibers need to have low surface energy

- The extended degree of roughness should be created.

One of the promising methods to synthesize the rough and hydrophobic coating for fibers is utilization of a combination of a surface attached polymer layer and nanoparticles. The surface layer consisting of a low surface energy polymer will bring hydrophobicity to the fiber surface whereas nanoparticles will create necessary topography.

Application

These water repellent fibers are used in the production of outdoor sports wear general clothing industrial fabrics tents etc.

- PERFUMED FIBRES

The perfumed fiber Esprit De Fleurs produced by kanebo was First exhibited in 1987. It is made up of fibers to which resin-made microcapsules of 5-10ƒÝm in diameter containing perfume essence are bound when the microcapsules are pressed and broken, the perfume is released.

Applications

The Esprit de fibers can be used in scarves, T- shirts, handkerchiefs, hand knitting wools, stocking etc.

- MIRROR FIBRES

It is high performance mirror in the shape of hair like flexible fiber. A team of researchers at the Massachusetts Institute of Technology has created high-performance mirrors that can be formed into hair-thin fibers and woven into fabrics or even paper.

Unlike traditional metal mirrors which build on the intrinsic reflectivity of the metal material, these reflective devices are composed of layers of non-metallic materials that reflect due to their layered structure. Mirror fiber uses multiple layers of two materials — a polymer, or plastic, and a chalcogenide, an inorganic glass substance. The large difference in the index of refraction between these materials causes a strong backward scattering of light, leading to high reflectivity.

Applications

- When incorporated into paper, the super-thin fibers could create hidden “bar codes” that would be visible only when scanned by specific colors of light. That could lead to documents that would be nearly impossible to forge or duplicate.

- Future fabrics woven with the mirror fibers and other materials, for example, could create clothes that reflect and protect against invisible microwaves and radiation. And depending on how the mirror fibers are developed, they might even lead to clothes that can change colors like a chameleon.

- These fibers could also be used as filters for Telecommunications applications.

BIODEGRADABLE FIBRES

With increasing concerns regarding the effect the textile industry is having on the environment, more and more textile researchers, producers and manufacturers are looking to biodegradable and sustainable fibres as an effective way of reducing the impact textiles have on the environment. The emphasis in Biodegradable and sustainable fibres is on textiles that are beneficial by their biodegradation and come from sustainable sources. Biodegradable and sustainable fibres open with a discussion of microbial processes in fibre degradation. It then moves on to discuss the major fibre types, including bast fibres, alginates, cellulose and speciality biodegradable fibres, such as lyocell, poly(lactic acid) and poly(hydroxyalkanoates). The development of synthetic silks is covered along with biodegradable natural fibre composites, nonwovens, and geotextiles. Also natural fibres are by definition biodegradable.

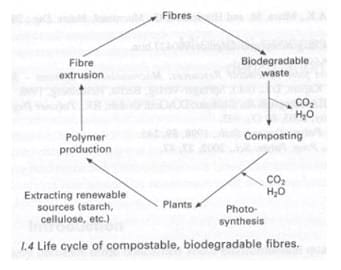

Life Cycle Assessment of Biodegradable Fibers

The life cycle assessment (LCA) of biodegradable fibers begins with the growing plant from which the fiber comes from. The LCA consists of plants growth by usage of carbon dioxide, water, and the interaction with the sun’s energy via photosynthesis. The next stage is the extraction of the plant fibers through mechanical and chemical processes to seperate unwanted components from the fiber material (i.e. cellulose). The third stage consists of polymer production where the material is cleansed or washed in different ways. This can be achieved with dissolving the materials (done with natural fibers), or melting the materials (done with synthetic fibers). Once changed into polymers, the liquified material is extruded through specially made spinnerets to get different size and shape fibers. Wet, dry, and melt spinning are the three different ways of fibre extrusion. The finished fibers are then treated and cleansed to then be used to make yarn. At the end of its use (i.e. clothing, home furnishing, etc.), the fiber becomes waste. The figure below illustrates this simple LCA of biodegradable fiber:

VARIOUS TYPES OF BIO-DEGRADABLE FIBRES ARE AS FOLLOWS:

- SPIDER SILK

What is spider silk made of?

It is a fibrous protein secreted as a fluid, which hardens as it oozes out of the spinnerets, which are mobile finger-like projections. As the fluid oozes out, the protein molecules are aligned in such a way that they form a solid; the process is not yet well understood. The spider hauls out the silk with its legs, stretching, fluffing it up or changing it in other ways to suit the purpose at hand. Spider’s silk is made up of chains of amino acids. In other words, it is simply a protein. The two primary amino acids are glycine and alanine. Spider silk is extremely strong it is about five times stronger than steel and twice as strong as Kevlar of the same weight. Spider silk also has the ability to stretch about 30- percent longer than its original length without breaking, which makes it very resiIient.

Properties

Spider silk is incredibly tough and is stronger by weight than steel. Quantitatively, spider silk is five times stronger than steel of the same diameter. It has been suggested that a Boeing 747 could be stopped in flight by a single pencil-width strand and spider silk is almost as strong as Kevlar, the toughest man-made polymer. It is finer than the human hair (most threads are a few microns in diameter) and is able to keep its strength below -40°C. The toughest silk is the dragline silk from the Golden Orb-Weaving spider (Nephilia clavipes), so-called because it uses silk of a golden hue to make orb webs.

Spider silk is also very elastic and capture silk (sticky silk for catching prey) remains unbroken after being stretched 2-4 times its original length. Spider silk is tougher, more elastic and more waterproof than silkworm silk so it could have a much wider range of applications. It is simple to see why spider silk is of such interest to materials chemists since new ultra-strong fibres based on the silk could be developed.

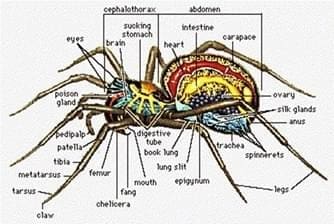

Production

There are seven types of silk produced by seven silk glands. A single spider does not possess all seven glands but has at least three if it is male (dragline, attachment and swathing silk) or four if it is female. The additional one is for egg sac silk. The seven types of gland are:

- Achniform gland: swathing silk.

- Cylindriform gland: egg sac silk.

- Ampullate glands (major and minor): non-sticky dragline silk. Silk from the minor ampullate gland is only half as strong as that from the major gland.

- Pyriform gland: attaching threads – attachment discs are made which anchor a thread to a surface or another thread.

- Flagelliform gland: core fibres of sticky silk.

- Aggregate gland: outer part of sticky silk droplets of an adhesive substance is deposited along the threads.

The glands are located on the lower side of the abdomen (see diagram below) and contain a watery fluid known as ‘dope’. This fluid passes through to the spinneret via a multitude of microscopic tubes where water recovery and solidification begins. Fluid from different glands can lead to the same spinneret so silk with specific properties required for a particular function can be produced. There are usually three pairs of spinnerets but this can vary between 1 and 4 pairs depending on the species. The substance exits through the spiggots which are mobile, finger-like protrusions and the resulting silk emerges as a solid. There are many spigots so many fibres are bound together like a cable. The diameter of a single fibre is controlled by the muscular action of a valve. The faster and tighter the strand is drawn, the stronger the silk.

Applications

- Swathing silk for the wrapping and immobilisation of prey.

- Webs for catching prey using sticky silk – it is elastic to prevent the prey from rebounding off the web.

- Draglines which are used to connect the spider to the web, as safety lines in case a spider should fall and as the non-sticky spokes of the web. Dragline silk is the strongest kind of silk because it must support the weight of the spider.

- Parachuting or ballooning which is used to aid the dispersal of young and to find new areas as a food source. Silk is released and is caught by the wind to lift the spider up into the air – flying spiders

- Shelters such as burrows or nests

Mating: male spiders weave sperm webs on which they deposit sperm and subsequently transfer it to their front palps, ready for placing on a females genital organs. Some species make a web and coat it with sex pheromones to attract a mate.

Some interesting web facts:

- Not all spiders weave webs.

- Spiders do not stick to their own web because only the central spiral part of the web is sticky, not the spokes. The spider knows where to tread!

- Webs lose their stickiness after about a day due to factors such as dust accumulation and exposure to air. In order to save energy the spider eats its own web before making a new one so the protein used for the silk threads is recycled.

INTERESTING FUTURISTIC APPLICATION

Spider Silk Could Weave Biodegradable Computer Chips

Spiders and some insects use silk to build strong webs and spin cocoons, and now scientists have figured out how to use the material for something even more amazing: electronic computer chips. In addition to other important properties discussed silk also has properties that make it ideal for use in electronic devices. Light can travel through a silk strand as easily as it does through a fiber optic cable. It is possible to transmit laser light down a short strand of the silk on an integrated circuit chip. With a coating and further development, the silk could one day have better transmission capabilities.

The achievement could open the door to medical applications, such as silk fibers carrying light to places in the body for internal imaging. Because spider silk is incredibly thin — roughly five microns in diameter or 10 times thinner than a human hair – surgeons could perform diagnostic exams using very small openings in the body. Because it is fully biodegradable, electronic silk technology could potentially become widespread.

- POLYLACTIC ACID

PLA fibres has many potential uses in non-wovens, spinning & filler material. It is easily converted into variety of fibre forms using conventional melt spinning process. PLA fibre is biodegradable under right conditions therefore well suited for waste treatment through composting. PLA minimizes environmental waste, as it may be fully biodegraded by microorganisms under appropriate conditions into carbon dioxide and water.

Properties:

PLA fibre is more hydrophilic than PET, have a lower density, have excellent crimp & crimp retention. Shrinkage of PLA material & thermal bonding temperatures are readily controllable. The PLA fibre tend to be stable in ultra-violet resulting in the material which shows light fading. They also offer low flammability & smoke generation characteristics.

Applications:

Major applications of PLA fibres & non wovens include, but are not limited to clothing & furnishing such as drapes, upholstery and covers. Some exciting potential applications include household & industrial wipes, diapers, feminine hygiene products and disposable garments etc.

- BACTERIAL CELLULOSE

Bacteria produce cellulose called bio- cellulose or bacterial cellulose. Plant cellulose and bacterial cellulose have the same chemical structure, but different chemical and physical properties.

Applications:

The bacterial cellulose works as a coating for life. It is used as an artificial blood vessel for microsurgery. Also used to make artificial leather , skin substitute and wound healing bandages. Our new composite fibers consist of a strong core coated with a drug-releasing, or ‘eluting,’ solution. They combine strength with the desired elements necessary for drug delivery, so they can be used as the basis of biodegradable drug-eluting stents.

Fibers to mend cancers and brain tumors

Biodegradable drug-eluting fibers only five times the thickness of a human hair can be applied in cancer treatments as well, particularly for cancers in hard to reach and sensitive areas such as in the brain, or in small children. When you take a tumor out of the brain, you can’t ‘clean’ the surrounding brain tissue attempts to do so may lead to additional tissue damage. But if you left our biodegradable drug-loaded fiber in the brain, it could do the work, then disappear when it’s no longer needed. And since the fibres are thin and delicate, laparoscopic methods can be used for their insertion, further increasing the chances for a full recovery.

- COLLAGEN FIBRES

Collagen is a protein fiber obtained from bovine skin. It consists of three polypeptide chains arranged in triple chain helix. These triple- chain helixes Assembles in to micro fibrils and then fibrils.

Structure & Uses

Collagen fibers form the basic structural components of extracellular matrix (ECM) of vertebrates that serve to:

- Store elastic energy during muscular deformation,

- Transmit stored energy into joint movement

- Transfer excess energy from the joint back to the attached muscles for dissipation.

They also act as mechanotransducers by transferring stress borne by the musculoskeleton to the attached cells in order to either up – or down – regulate tissue metabolism as a result of changes in mechanical loading. Finally, they prevent premature mechanical failure of tissues by limiting deformation of most ECMs and organs.

Applications

Collagen fibers are the major constituents of tissues termed extracellular matrices (ECMs). ECMs make up the structural components of surface and internal linings found in the human body, connections in musculoskeletal and oral tissues, walls of conduits and holding structures of the cardiovascular system and gastrointestinal tract.

Collagen has an excellent biocompatibility which makes it a popular choice as a major component of artificial issue and would dressing. Collagen products such as sutures can readily be accepted by body because of their low immunogenicity.

- 5. CHITOSAN

Chitosan is a natural biopolymer that is derived from chitin. Chitin is the most abundant natural amino polysaccharide and estimated to be produced annually almost as much as cellulose.

Properties:

Chitin & chitosan are of commercial interest due to their high percentage nitrogen (6.89% ) compared to synthetically substituted cellulose. This makes chitin a useful chelating agent.

Applications :

Chitin & chitosan are unique material for versatile applications. It has applications in areas of pharmaceutical & biomedical industries (Properties are useful for wound treatment and it also used as excellent material for healing wounds.), paper industry, textile finishes, photographic products, cements, heavy metal chelating agents, cosmetics etc.

FUTURISTIC APPLICATION OF PRESENT FIBRES:

- Futuristic Fibers Could Replace Camera Lenses

Researchers at the Massachusetts Institute of Technology (MIT) in Cambridge found so-called multimaterial fibers can turn incoming light waves into images without the need for a camera lens. And unlike fiber optic cables, they can transmit images that have been captured across their entire length.

Current cameras rely on lenses to produce a recognizable image. The curved glass or plastic of a lens focuses light waves reflected off an object onto a surface that can display the resulting images, either film or, in the case of digital cameras, charged-coupled devices. The idea has worked well for decades, but it’s always contained an Achilles’ heel: Damage the lens, and you lose or diminish the ability to see.

The multimaterial fibers developed by the MIT team could solve this problem and provide a host of other benefits. The multimaterial fibers consist of an array of metal electrodes connected to a semiconductor and are covered by an insulating polymer sheath. The semiconductor layer in the fiber detects light and relays signals via the electrodes to a microprocessor, which combines the signals from an array of the fibers to determine the light’s intensity, direction, and color. Visualization software then takes that data and recreates the source image and displays it on a monitor screen. And the whole process is accomplished without a lens.

- Putting spark into Cotton

Chinese and US researchers have made cotton fibres conduct electricity by coating them in carbon nanotubes. These ‘cotton wires’ feel and behave like ordinary cotton – allowing them to be easily woven into fabrics – and can be modified to detect blood. The research is a step towards futuristic clothing, perhaps capable of monitoring biological functions such as heart beat, perspiration or insulin levels, say the scientists.

CONCLUSION

Natural fibers have good properties but have some limitations; to overcome those synthetic fibers are produced. Still they have some drawbacks, to remove them developments are going on. The new performance fibers, which have been introduced today, have applications in the above fields of medical, sports, aero/space industry, transportation industry, civil engineering and construction industry and defense industry. These fibers serve as fibers with high temperature resistant and numerous advantages over traditional materials. Higher strength, lighter weight, higher operating temperatures and flame-retardant ability are some of the most prominent features of these fibers. Fibres can replace even metals, so enormous developments are done in fiber field. Now the aspects of eco-friendly, environment friendly (fiber) have come in future.

These outstanding properties create opportunities to manufacture products that historically could not be made due to technical constraints. The functional fibers are used in an increasing range of functional application, including flexible technical textiles like sports materials and hygiene medical applications with high compatibility, where their ability to meet demanding requirements makes them an effective choice.

The bio- fibers are environmental friendly fibers so it has been more demand in future.!

The development of special fibers is the consequence of merging fundamentals scientific and technical knowledge, as there is a quest for high performance fibres. Thus, constant and continued endeavors of fibre scientists jointly ventured with material technologies had made dreams into reality. These special fibres totally provide the potential for providing new technology.

References

- sciencemag.org

- chinapost.com

- springer.com

- slideshare.net

- com

- tasfish.com

- naturalnews.com

- fibre2fashion.com

- chm.bris.ac.uk

- newscientist.com

- wired.com

- eetasia.com

- go.com

- hindu.com

- ntcresearch.org

- ncbi.nlm.nih.gov

- buzzle.com

- jeffjournal.org

- woodheadpublishing.com

- cambridge.org

- fibersource.com

- technicaltextile.net

- answers.com

- 2wtextile.com