INTRODUCTION

The environment and increasing greenhouse gases in this current era causing climate change is behind the recent trend of our drive towards applying upcycling practices. Not only as individuals but also in what we choose to wear. Reusing and repurposing what we wasted has been an eyeopener.

By looking at textiles with a new perspective. Designers are converting food waste into synthetic fibres. Producing biobased alternatives that is appropriate for use in apparel.

Majority companies or businesses have linear model of take-make-waste thinking, without thinking about after use.

Today, agriculture wastes and other organic wastes are being seen as a potential renewable, biodegradable material to be made into textiles.

Traditional textiles from natural sources like cotton and leather, may seem eco friendly but have environmental issues and hurt animals.

The alternative synthetic materials like nylon and polyester are also not exactly good for the environment. Made from fossil fuels, they biodegrade like plastics. Petroleum based materials are damaging our plant. Therefore, we are turning to waste to provide solutions to reduce our carbon footprint.

ORANGE PEEL TO FABRIC

Orange Fiber, Italian label and product invented by Aderiana Santanocito and Enrica Arena. They converted citrus juice by-products into a sustainable fabric; a silky acetate made from the waste generated by Sicily’s orange juice industry.

PROCESS OF CITRUS WASTE TO FIBRE

Globally, 7,00,000 tons of citrus peel waste every year are thrown away in landfills without proper recycling alternatives. Orange fiber came up with a textile, made by recycling the cellulose from the fibres that are discarded from the pressing of whole oranges to make orange juice. Orange peel waste was collected from the local juice makers in the city and washed, cleaned, processed them.

The grounded orange peel waste is processed with their patented technology ‘Pastazzo’, that separates the cellulose from the material. This will be then mixed with material and made into a filament, which can be used for weaving or knitting, or a blend with silk and cotton to make satin and poplin. 100% orange peel waste fibre is also available which is similar to viscose. It can be dyed, printed, and even washed like other conventional materials.

MECHANISM

The peel of citrus fruits is composed by two portions, epicarp/flavedo, colored portion of the peel and mesocarp/albedo, inner white, highly rich in cellulose.

- Extraction from inner skin of orange peel

Alpha cellulose is obtained from the inner white-colored portion of peel of orange (mesocarp/albedo), which can be spun and form filaments. Extraction procedure is chlorine-free.

Preparation of a cellulose yarn by a cellulosic material composed of alpha-cellulose extracted from orange.

Treating raw material derived from citrus fruits with 2% hydrogen peroxide in basic and optionally in acid conditions with 0.5-6 wt % sodium hydroxide.

Carried out at a temperature from 65° C. to 90° C. with pH of 11 to 12, solution is filtrated. The solid comprising cellulose is recovered. After filtration, it is washed with distilled water and optionally with acetone. Washing is carried out until a neutral pH is achieved. The solid recovered after filtration is air dried or dried in an oven.

- Extraction from both outer and inner layer of orange peel

When the raw material comprises both the albedo and the flavedo, it is treated with solvents, preferably ethanol and toluene, before extraction.

the raw material deriving is suspended in a solution of hydrogen peroxide and heated under mechanical stirring. Temperature is kept between 65° C. to 80° C, pH of 11-12 with sodium hydroxide. Then the solution is filtrated and a first solid is recovered. The solid then undergoes extraction into a solution comprising, acetic acid and/or formic acid, to which hydrogen peroxide is added. Temperature kept 60° C. to 90° C, filtered then a second solid is recovered, which is suspended in a solution of 0.5-6 wt % sodium hydroxide. With temperature from 90° C. to 110° C., and a final cellulose product is recovered by filtration.

The cellulose obtained comprise alpha cellulose in amount equal or greater than 90 wt %.

PROPERTIES OF PASTAZZO TECHNOLOGY

This process differs from the conventional methods of extraction of cellulose like wood, which employs chlorine containing agents. It may react with cellulosic material and form toxic organochlorine.

Nanotechnology and microencapsulation were employed to retain the beneficial properties of citrus fruits on to fabric, maintaining these properties till 20 washes

essential oils and vitamin C that are present which the skin absorbs and is nourished, making the fabric a wearable body cream. But its not greasy.

Resembles silk in terms of softness, touch and shiny surface.

Instead of using new resources, it saves land, water and fertilizers, by using waste by products, and thus reducing environmental pollution.

Lightweight and biodegradable material. Textiles from recycling orange peel waste are considered to be a sustainable alternative as it uses a lesser carbon footprint compared to conventional textile production.

It can be blended with cotton, silk, elastane, and pineapple or any existing yarn. It can be opaque or shiny according to requirements of the designer.

APPLICATIONS

Boiling of peels, fresh or sundried, releases a light orangish-yellow colour to the water. Suitable mordant can be added to hold the dye on to the fabric. The resultant fabric is a light shade of yellow along with a sweet citrus smell. Can be used in functional clothing and sports textiles.

Wasted peels of orange and lemon with alum and sodium carbonate (30% mordants) gave good quality in shade and fastness. Isolate pectic acid from citrus peel waste by acid hydrolysis. Mixed with a thickening agent and used as a printing paste to print designs on textiles. Sodium alginate gives better dye take up, brightness in shade and wash fastness.

Grinded orange peels are used a textile finishing agent. Extracts combined with sodium bicarbonate, coated on a cotton fabric resulted in appreciable anti-odour and anti-microbial properties on the fabric. Can be used in medical textiles.

Friction occurred during washing decreases the efficacy of the active agents and their anti-microbial activity. Alkaline binder gives better performance properties.

Orange peel and papaya skin with silver nanoparticles combined induces anti-microbial properties to the fabric.

Peel dried, powdered and coated on the fabric using padding mangle was found to perform as an effective mosquito repellent fabric. The active extracts of limonene extracted from orange peel using the ultrasonic waves were converted into micro-capsules (microencapsulation) and further coated on the cellulosic fabric for better insect repellent property.

Properties of UV protection, self-cleaning, anti-microbial, antioxidant and a mild fragrance can stay up to twenty washes.

Applications in other areas like insulating material in building construction, a remedy for the oil spill, manufacturing of handmade paper. a good print transfer medium, transfer ink from one surface to another, variety of surfaces like wood, mica, paper, clothes, glass, human skin. An effective dye adsorbent, remove toxins and organic pollutants from the textile effluent water.

The orange peel waste can be used as cattle feed, compost, a soil amendment, perfumes, cosmetics, essential oil, polystyrene production, limonene extraction, as bio-adsorbent and as a source of carbon, biochar, and bio-fuel.

ORANGE FIBER IN FASHION INDUSTRY

Orange Fiber patented technology won several awards, including UNECE Ideas for Change Award in April 2015. Their idea was purchased by international brand H&M, and launched the Conscious Exclusive line 2019 collection.

Victoria Albert Museum in London organized on an exhibition displaying 300 works on the title ‘Fashion from Nature’, displaying over 300 garments along with the Ferragamo Orange Fibre Collection.

Salvatore Ferragamo, created high-end shirts, dresses using orange fibre and many designs that they launched as Capsule collection on Earth day. Citrus peel and pineapple leaf fibre were combined with Italian silk and embroidered with vegan material.

Chiling Lin, Taiwanese actress and model, was spotted wearing the Orange Fiber gown at the Global Change Award 2018.

EXPIRED MILK TO FABRIC

In the early 1900s German chemist Frederick Todtenhaupt attempted to turn milk byproducts into a silk substitute, but his efforts came to no fruition.

In the mid-1930s, Italian company SNIA Viscosa began producing milk-based fabric at large scale, but its fibres came apart.

Sour milk is a wasted potential, which can turn into yarn and clothes. As it is not suitable for human consumption, millions of tonnes of it are disposed every year. The protein casein present in milk is extracted to produce this soft fabric.

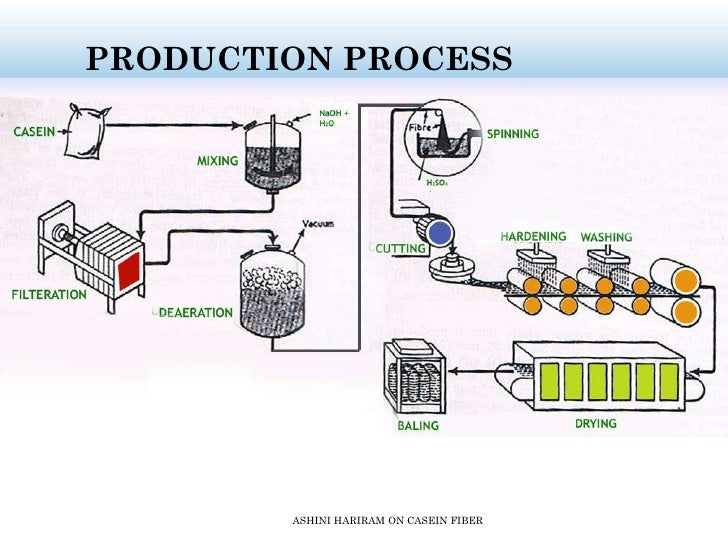

MECHANISM

The protein casein is obtained by the acid treatment of skimmed milk. Coagulation at 45° C. by means of acids at around pH 4. It is washed, dried and ground to a fine powder. Casein is dissolved in caustic soda solution, which is allowed to ripen until it reaches a suitable viscosity, and is then filtered and deaerated.

The spinning solution is wet spun by extrusion through spinnerets into a coagulating bath containing sulphuric acid (2 parts), formaldehyde (5 parts), glucose (20 parts) and water (100 parts). The jets of solution coagulate into filaments.

Following the coagulating bath, bunches of filaments are collected together into a tow. Hardening treatment is done with formaldehyde, minimizing the softening effects of water.

The filaments are subjected to drawing at this stage. After treatment, the tow is washed and dried, crimped mechanically, and then cut into staple fiber.

PROPERTIES OF MILK FABRIC

Milk fibre contains eighteen amino-acids, which is beneficial, functions as nourishing skin. pH level is same as human skin, feels soft and good on skin. A great option for people with sensitive skin and rash prone.

Smooth and silky feel, cheaper than silk. Easy care, does not have smell of milk.

Resembles wool, naturally crimped, soft, warm handle and resilient. It provides good thermal insulation.

Antibacterial, antiallergic, non-flammable properties. Absorbs moisture and temperature regulating.

Environment friendly and easy to compost. Uses 60% less water than the making of an organic cotton shirt. No extra resources were used that may harm the environment.

APPLICATION

Anything that is in contact with skin – interior of Automobile industry, in home like bedding and sofas. In medical field like wound dressings. It has silk and wool properties, therefore combining it in sportswear or outerwear can be beneficial.

It can be blended with cotton or nylon, used for interlock outerwear, T shirts, cardigans, jumpers, coatings, blankets. Blending with wool to make pressed felts, for use as floor coverings and carpets. Production of multi-component nonwovens.

Packaging from biopolymers can one day replace plastics.

MILK FIBRE IN FASHION INDUSTRY

Italian designer Antonella Bellina, founder of Duedilatte, gave a second life to milk waste. After heating the spoilt milk, citric acid is added to separate the protein casein, which is dried and ground into a powder. Machine spinner turns it into fibre, resembles cotton like thread. The resulting fiber is white in color. She uses natural dyes such as strawberry or coffee. The liquid material left with after extracting the casein from the milk can be used to feed farm animals, thus wasting nothing.

Microbiologist and designer Anka Domaske, founder of Mademoiselle Chi Chi, produced a bright summery collection with milk fabric. Qmilch, is her patented spinning process, with no use of chemicals. Zero waste and energy efficient procedure. Celebrities Mischa Barton and Ashlee Simpson have been seen wearing her Qmilch clothing.

Mi Terro is another company working with wasted milk. Providing solutions in fashion, healthcare and packaging industries.

Lanati Milk Yarn is Atom’s compression socks knitted with milk fiber. The fibers are cooling and moisture wicking, and has UV protection properties. They are gradually adding women’s shapewear, men’s compression wear and baby wear, with special knit technique has inbuilt stretchability. One size fits 6 months to 3 years old, with a ‘memory’, gently moulding the body without any discomfort.

FISH SKIN WASTE TO FABRIC

Two billion pounds of fish and crab by-products are being discarded into the ocean annually. Craig Kasberg of Tidal Vision, found a way to use fish by-product that support fisheries managed sustainably by going directly to the source. The only by-product of the process is an organic fertilizer.

The Hezhe ethnic tribe, or Nanai people, of the Far East, known as the “fish leather tribe”, make their traditional clothes out of fish leather. Their earliest work dates back to 18th century.

PROCESS

Aquatic salmon leather produced by using vegetable based foodgrade materials instead of harmful chemicals. Vegetable tanning based on tannins (polyphenols and gallic acid) which are found naturally in plant species. Tannins binds to the collagen proteins and coats them, causing them to become less water-soluble, flexible and more resistant to bacterial attack.

Tannins are found in around 300 different plant species worldwide with varying concentrations. In wine, chestnuts, black and green tea, sawdust, olive leaves, rhubarb roots, oak, spruce bark, cecidia etc.

No formaldehyde, no chrome based tanning chemicals to dispose of. They have come up with a way to remove dry skins without any manual labour. Resin is heat pressed into salmon skin, providing durability and glossy finish.

PROPERTIES

It is biodegradable, biocompatible, and nontoxic, naturally inhibitive to bacteria and microorganism growth.

A better alternative to the silver nanoparticles which are a heavy-metal toxin that absorbs into the skin and washes out of clothes, polluting waterways.

It is stronger and more durable, has natural cross-fiber structure unlike the fibers in cow leather, which run in one direction. It is softer in texture compared to snakeskin leather.

APPLICATIONS

In the upholstery industry as sustainable leather couches and chairs. In foot wear, as it is soft and flexible compared to conventional leather. A guitar company wants guitar cases made out of salmon leather.

SALMON LEATHER IN FASHION INDUSTRY

Tidal vision created the vegan leather to make wallets, phones cases.

Designer Isaac Mizrahi created an ivory short chiffon dress and jacket featuring textured salmon leather pailletes, or sequins, which mimics the scales on a fish.

CONCLUSION

Sustainable production by reusing by-products that would have otherwise been discarded and polluted the environment. Innovators have focused on unwanted materials as a way of maximizing usage. Collection of heaps of pre-existing consumer waste to recreate another product in fashion and other industries. Approach to waste as a valuable raw material in development, thereby, transforming the textile and fashion industry towards a sustainable future.

We have observed banana and pineapple leaves as raw materials for fabric, however, using discarded foodstuff are solving issues of pollution, contamination of land and large consumption and waste.

REFERENCES

- http://stdj.scienceandtechnology.com.vn/index.php/stdj/article/view/1730

- Production of textile from citrus fruit, Adriana Maria SANTANOCITO and Elena Vismara

https://patents.google.com/patent/US9771435B2/en

- https://www.livekindly.co/italys-orange-fiber-sustainable-vegan-silk-cruelty-free/

- https://amberoot.com/blogs/blog/future-of-fashion-innovative-fabric-orange-fibre

- http://orangefiber.it/en/

- https://fashnerd.com/2019/04/orange-fiber-x-hm-conscious-collection-reinventing-fashion-in-a-greener-way/

- http://www.feteafete.com/blog/mademoiselle-chi-chi-qmilch-eco-fashion-made-from-milk.html

- https://fashionunited.uk/news/fashion/sustainable-fabrics-italian-brand-duedilatte-makes-clothing-from-sour-milk/2019030141896

- https://gpidesign.com/2016/11/meet-the-makers-textiles-made-from-milk/

- https://www.qmilkfiber.eu/qmilk-faser-modische-anwendung?lang=en

- https://www.smh.com.au/lifestyle/fashion/milk-fibre-dresses-a-hit-with-celebs-20111013-1llwg.html

- https://atom.fit/pages/lanati-milk-fiber

- https://welum.com/article/qmilk-new-generation-fabrics/

- https://thefishsite.com/articles/alaska-fish-factor-tidal-vision-upcycling-seafood-byproducts

- https://www.ijcmas.com/7-4-2018/Neha%20Chauahn,%20et%20al.pdf

- Process for Producing Milk Protein Fibers and Milk Protein Fiber Products Obtained Therefrom, Inventor Anke Domaske https://patents.google.com/patent/US20130256942A1/en

- http://www.takepart.com/feature/2016/05/23/food-upcycling-fashions

- http://parsonsmaterialslibrarian.blogspot.com/2011/04/salmon-leather-new-eco-friendly-leather.html

- https://www.synzenbe.com/blog/salmon-leather-a-sustainable-and-exotic-material-for-the-future-644/644