Basics of pollution & pollutants, source of pollutants & Chemical Hazards.

This is specially focused on producing textile end products used for fashion & luxuries life in a non-toxic, ethical and sustainable manner. It also highlights the methodology – How to produce sensuous fabrics which are eco-friendly & not harmful to human beings & the surrounding environment.

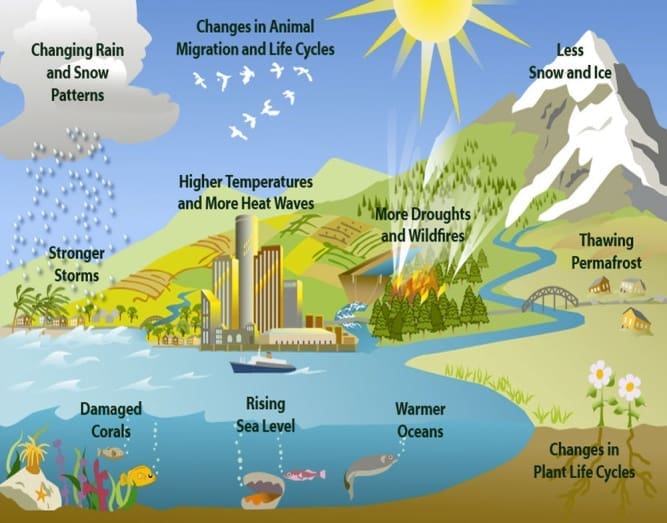

The textile industry in India is a gigantic industry – and it is gigantically polluting. The textile industry uses copious amounts of two things: water and chemicals third-largest pollution-generating industry after Leather & paper. This industry is a unique industry where the designer wants to touch the emotions of the human – the ultimate user. When this industry moves towards fashion, it is ultra-dynamic in nature & it changes at every moment. In this era of global warming, it is very clear that we stand at a turning point. For the first time, humans are no longer just affected by weather cycles & affecting natural seasons & climatic cycles – and also suffering the consequences of doing so.

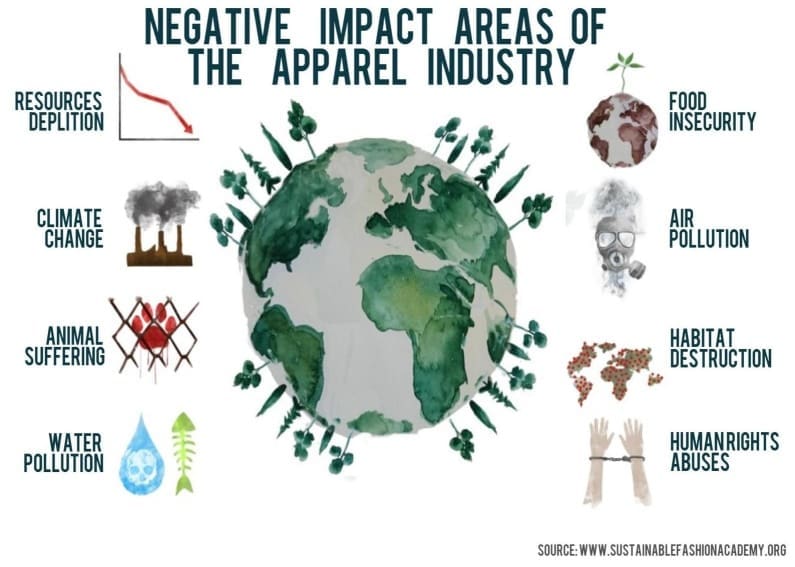

Climate change is one of the most pressing problems of the 21st century. It affects everything, right from the air we breathe, the water we drink, the food we grow & eat & the clothes we wear. Also, the textiles we consume on daily basis are produced in a harmful manner right from cultivation to disposal. This is because the chemicals used during the life cycle of garment releases harmful pollutants which affect nature including human being.

Water is used at every stage in the fabric manufacturing process to dissolve chemicals to be used & then to wash and rinse out those same chemicals to be ready for the next step. It takes large amounts of chemicals to produce fabric. The production of the one T-shirt (right from cultivation to disposal) consumes approximately 4000 Litres of water & a huge amount of chemicals. The chemically infused effluent – saturated with dyes, de-foamers, detergents, bleaches, optical brighteners, softeners, stiffeners, and many other chemicals – is often released into the local river, where it enters the groundwater, drinking water, & gives adverse impacts on flora, fauna, and our food chain. One should note the seriousness of this & try to understand that, many of these chemicals remain in the fabric that gets absorbed through human skin during usage. Over a period of time, we abrade tiny particles of the fabric that we then ingest or inhale. One Kg of cotton fabric conventionally processed into fabric contains 75% cotton fibers and 25% chemicals, many of which are proven toxic to humans and animals. These chemicals get mixed with local water reservoirs/rivers & pollute them. Just imagine living without fresh food & water. In India, alone the textile industry consumes water quantity equal to around 2 million Olympic size swimming pools every year that too release largely untreated. The use of chemicals and dyes during the manufacture of textiles generates an enormous quantity of waste as sludge, fibers, and chemically polluted waters. As a consequence of such high quantities of solid & liquid waste, textile industries are now facing major problems in environmental pollution.

While understanding the basics of Textiles, it leads to a variety of chemical operations and materials. Let us accept the truth that, Textile is the only material which is in contact with human skin for 24 hours & any pollutant present on fabric surface is tend to accumulate on the surface of the skin or accumulate in fat tissues & harm the body it is also harmful to mother earth when it is released to the atmosphere by the way of production activity, frequent washes at the user end, & also at the time of disposal after use. Textile contributes a range of potential hazards to its workers and the surrounding communities and environment. Chemicals are frequently used in workplaces & some of them are by nature hazardous. It is essential to understand the chemical nature & its impact on the environment before application & should try to eliminate such chemicals. Many scientists have worked deeply on this subject & derived a list of chemicals in textiles – popularly known as RSL (Restricted Substances List) In addition to this, as a further activity, they released a list MRSL (Manufacturers Restricted Substances List) This leads to restriction of chemicals used during production activity. This is because large numbers of manpower being used in textile production activity & they can have the adverse effect of pollutants & lead to developing harmful effect. European countries have worked in this connection & developed REACH document (REACH stands for – Registration, Evaluation, Authorisation, and Restriction of Chemicals ) REACH is a regulation of the European Union, adopted to improve the protection of human health and the environment from the risks that can be posed by chemicals, while enhancing the competitiveness of the EU chemicals industry. It also promotes alternative methods for the hazard assessment of substances in order to reduce the number of tests on animals.

In principle, REACH applies to all chemical substances; not only those used in industrial processes but also in our day-to-day lives, for example in cleaning products, paints as well as in articles such as clothes, furniture, and electrical appliances. Therefore, the regulation has an impact on most companies across the EU.

REACH places the burden of proof on companies. To comply with the regulation, companies must identify and manage the risks linked to the substances they manufacture and market in the EU. It also helps to understand how the substance can be safely used, and they must communicate the risk management measures to the users.

If the risks cannot be managed, authorities can restrict the use of substances in different ways. In the long run, the most hazardous substances should be substituted with less dangerous ones.

It’s necessary for Employers to make necessary arrangements to ensure the safety and health of employees which handle, store, and transports chemicals. In order to make such arrangements, the employer has to evaluate work-related hazards or potential hazards and develop safety procedures and risk control measures.

What is Pollution:-

The contamination of soil, water, or the atmosphere by the discharge of harmful substances is known as the act or process of polluting or the state of being polluted,

Generally, pollution is an outcome of human activity & the impact of other living animals on the natural atmosphere.

The textile industry is one of the most pollutants releasing industries of the world. … Besides, 20 percent of all freshwater pollution is made by textile treatment and dyeing. Pollutants released by the global textile industry are continuously doing unimaginable harm to the environment. It is essential to have a sharp focus on pollution & pollutants created by the Textile industry.

Impact of pollution is observed on Air, Water & Soil.

It Disturbs the Natural cycles (seasonal changes) in the atmosphere.

Global warming Ozone layer depletion

There are three basic needs that a man possesses food, clothing, and shelter. When we think of pollution, we envision coal power plants, strip-mined mountaintops and raw sewage piped into our waterways. We don’t often think of the clothes on our bodies. The global textile and clothing industry is bound to be huge, as it fulfills the second basic requirement of man. The consumption of textile products is very huge & is increasing day by day due to increase of population & also increase in sq. meter consumption per person. Ultimately the overall impact the apparel industry has on our planet is quite large. Fashion is a complicated business involving long and varied supply chains of production, raw material, textile manufacture, clothing construction, shipping, retail, use, and ultimately disposal of the garment. It is said that textile is the second-largest polluter (after the paper industry) in the world. A general assessment says that, right from the pesticides used in cotton farming, the size used in fabric manufacturing, the toxic dyes used in manufacturing, and the great amount of waste generated during disposal of garments. Other supporting systems also generate lots of pollution load which includes coal for steam generation, transportation & packing material. Pollutants released by the global textile industry are continuously doing unimaginable harm to the environment. It pollutes land and makes them useless and barren in the long run. Surveys show that cotton consumes the highest amount of harmful pesticides and fertilizers. The majority of them fall on land while they are sprinkled on the crop. Similarly, textile manufacturing units release hazardous waste into the nearby land.

What are Pollutants:-

Here we link this word with chemical pollutants. The substance that pollutes something, especially water or the atmosphere is known as chemical pollutant. The textile industry is water intensive and produces pollutants of different forms. The manufacturing operation also generates vapours’ during dyeing, printing and curing of dye or colour pigments. Dust emission is associated with Fibre processing / boiler operation. Other than these process operations, textile mills have wood, coal or oil fired boilers and thermic fluid heaters which are point emission sources. Major environmental issues in textile industry result from wet processing. Wet processes may be carried out on yarn or fabric. The transformation of raw cotton to final usable form involves different stages. The various important wet processes involved in the textile industry are as follows

| Process | Pollutants |

| Sizing & Desizing | Enzymes, Starch, Waxes, CMC, PVA, etc.….. |

| Scouring & Bleaching | Hydrogen Peroxide, caustic, Soda ash, Sodium Hypo chloride, Pero stabilizer, Surfactant, Acetic acid, cotton wax, etc.….. |

| Mercerizing, | Caustic Soda, Cotton wax, etc. … |

| Dyeing | Dyes, Salts, Surfactant, Urea, Soda Ash, etc. … |

| Printing | Urea, Dyes, Pigments, Binder, Soda Ash, Thickener, etc. … |

| Finishing | Resins, Formaldehyde, PVA, Waxes, silicones, Polyethylene, etc. |

Sizing: This process involves the sizing of yarn with starch or polyvinyl alcohol (PVA) or carboxyl methylcellulose (CMC) to give the necessary tensile strength and smoothness required for weaving.

Desizing: The sizing components which are rendered water-soluble during sizing are removed from the cloth to make it suitable for dyeing and further processing. This can be done either through the conventional process of acid steeping or through enzymes.

Scouring / Bleaching: This process involves the removal of natural impurities such as greases, waxes, fats, and other impurities. The desired cloth is taken for scouring. This can be done either through the conventional method (kier boiling) or through modern techniques (continuous scour). Kiering liquor is an alkaline solution containing caustic soda, soda ash, Hydrogen peroxide, Peroxide stabilizer, with a small amount of detergent. This process removes the natural coloring materials and renders the clothes white.

Mercerizing: The process of Mercerization provides luster, strength, increases dye affinity and abrasion resistance to fabrics. It is generally carried out for cotton fabrics only for easy dyeing. Mercerization can be carried out with the help of highly concentrated caustic soda (250 to 300 GPL) with an alkaline stable wetting agent.

Dyeing & Printing: This is the most complex step in wet processing which provides attractive color on the product. Dyeing is carried out either at the fiber stage, yarn stage, or fabric stage. For the dyeing process, hundreds of dyes and auxiliaries are used. In the textile industry, various types of fibers are used which leads to different processes & various Dyes & chemicals printing paste add to a load of pollution drastically.

Finishing: The finishing process is a specialized process that leads to the use of various specialized chemicals & the ultimate pollution load is increased. The finishing chemicals are more harmful to human health & also are environmental hazards.

With the combination of all the above processes used in textile manufacturing, a large volume of water with various pollutants is generated & it needs to be treated in an Effluent treatment plant. There are two wars to reduce pollution load

1) By treating effluent in the correct manner with correct discharge norms.

2) By avoiding/reducing the use of chemical hazards in the process.

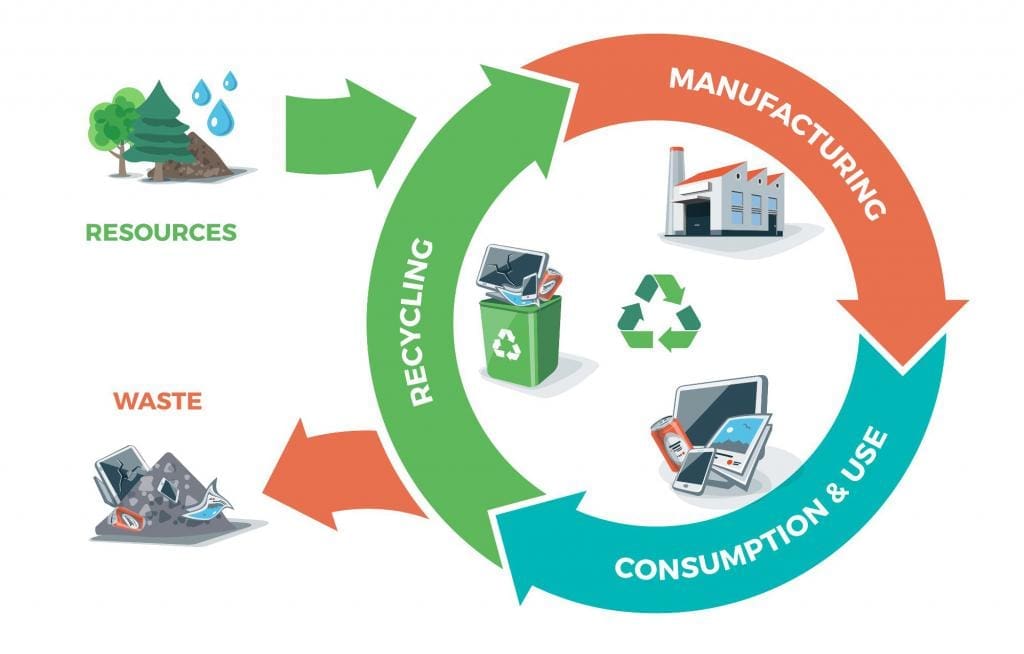

In the second option, one can select green chemicals which are no or less harmful & gets bio-degraded without adverse impact on the atmosphere. Green chemistry is a whole new way of thinking or entirely new production approach that helps in using the existing knowledge and fundamentals of chemistry and other sciences to decrease the negative impact environment is facing. Green chemistry is different processes and methods that can help in minimizing the effect of pollution or environmental deterioration.

It is a combination of chemistry and chemical engineering for the betterment of the environment. There are several processes in the textile production line, that not only add to the environmental pollution but processes are not cost-effective and harmful to the environment. These processes are the cause of hazardous waste generation. Moreover, disposal of by-products (Sludge) & also garments after usage are dumped & are the cause of environmental pollution. The process should be such that even though the garments or by-products cannot add anything gainful but it should not add to the environmental pollution.

Importance of Green Chemistry

Therefore, it is important to utilize the presently available knowledge to reduce the chemical hazards and also help in developmental activities. This should form the basis of green chemistry. So, what are the measures that need to be taken? For instance, we should be careful while using certain highly toxic organic solvents like toluene, benzene, carbon tetrachloride, etc.

It is fact that the textile industry is a highly water-consuming industry. In addition to this, the effluent characteristic and effluent quantity vary according to the processes involved, chemicals used, and the scale of operation. Therefore, the quality of effluent from one industry varies from the industry. As the textile manufacturing units use different types of raw materials, chemicals, and processes. As per market demand, textile units change their product mix & lead to variation in effluent characteristics which leads to difficulties in treatment at ETP. Avoiding the use of hazardous chemicals is the only solution for pollution prevention.

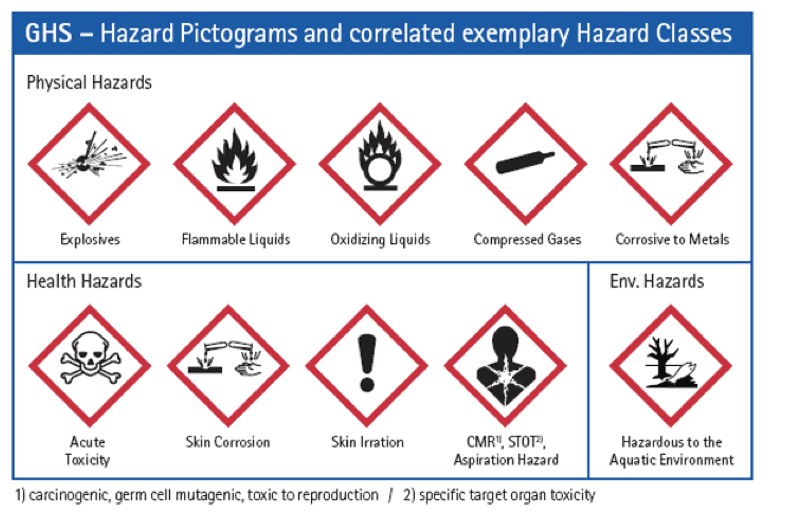

There are three types of chemical hazards

| Type of

Chemical Hazard |

Impact of Hazard | Precautions to be taken |

| Physical hazard | Cause fire | Proper storage of chemicals |

| Explosive | ||

| Corrodes equipment, plant & machinery | ||

| Causes violent reactions when used with other chemicals in the process | ||

| Human health hazard | Skin – eye irritation | Use of proper Personal Protective Equipment’s |

| Cause allergies | ||

| Cause cancer | ||

| Damage organs | ||

| Affect fertility & reproduction | ||

| Dusting / Odour | ||

| Endocrine disruptor | ||

| Environmental hazard (This segment is a focused area) | Toxic to aquatic life | Avoid the use of

Chemicals |

| Toxic to terrestrial life | ||

| Persistent | ||

| Bioaccumulative | ||

| Contaminates soil, air & groundwater |

It is essential for a technician to know the chemical he uses & its impact on the environment.

Chemical hazards are further categorized by their chemical nature into 11 priority groups as under;

- APEO

- Phthalates

- Azo Dyes

- Brominated & Chlorinated Flame retardants

- Chloro-phenols

- Chlorinated aromatics

- Chlorinated solvents

- Organotin Compounds

- Short Chain Chlorinated Paraffin’s (SCCPs)

- Heavy metals

- Per-fluorinated Chemicals (PFCs).

The restrictions on these chemical groups were imposed as & when its severity was identified. The above pic shows the year when a particular hazard was banned (Pic is from the IKEA brand)

In order to reduce the use and impact of harmful substances in the industry, it is essential to focus on the entire supply chain starting from fiber generation to end consumer to disposal. This includes suppliers of raw material & chemicals, production houses, accessories manufacturers, packaging material suppliers, screen-printers, laundries, etc…

RSL & MRSL: – Restricted Substances are chemicals whose use or presence is banned in a particular end-product such as a finished article or garment. Restricted Substances List or RSL is a comprehensive list of all chemicals that are restricted or banned from use on products. RSLs are developed individually by Brands, Eco-labels, or legislations and are continuously updated based on international, federal, and local governing bodies. MRSL is the next step to control the use of restricted substances right from the manufacturing stage. The MRSL differs from an RSL because it restricts hazardous substances potentially used and discharged into the environment during manufacturing, not just those substances that could be present in finished products. The MRSL takes into consideration both process and functional chemicals used to make products, as well as chemicals used to clean equipment and facilities. It addresses ANY chemical used within the four walls of a manufacturing facility. Thus MRSL has broadened the area of RSL.

A typical RSL manual contains the following:

- Substance name

- CAS Number

- Limit Values of each restricted group

- Terms such as Not Detected and Detection Limit

- Test Method

- Regulations under which the chemical group is restricted.

RSLs Focus on End-Product: Certain chemicals used at different stages of production are released into the environment through wastewater, air, or sludge. RSLs are focused only on restricted substances in the end product and do not monitor the presence of these chemicals in wastewater or sludge. RSL compliance is monitored only through random testing on the samples of the finished product. But, this is like solving the problem after the damage has been done! Due to these limitations, Brands have shifted focus from RSLs to Manufacturing RSLs or MRSLs. One must understand the difference between RSL & MRSL.

RSLs Focus on End-Product whereas MRSL Focus on Usage of Chemicals: – Certain chemicals used at different stages of production are released in the environment through wastewater, air, or sludge. RSLs are focused only on restricted substances in the end product and do not monitor the presence of these chemicals in wastewater or sludge. RSL compliance is monitored only through random testing on the samples of the finished product. But, this is like solving the problem after the damage has been done! Due to these limitations, Brands have shifted focus from RSLs to Manufacturing RSLs or MRSLs. One needs to understand the difference between RSL & MRSL.

| RSL / MRSL | RSL | MRSL |

| Definition | RSL is a list of hazardous chemicals that are restricted below a certain threshold in finished textile products. | MRSL is a list of hazardous chemicals that are restricted below a certain threshold in textile, apparel, and footwear manufacturing. This list includes process chemicals, which may be used in manufacturing but may not be present in the finished product. |

| Criteria | Provides threshold limits of hazardous chemicals allowed in finished products | Provides threshold limits of hazardous chemicals allowed in chemical formulations |

| Identification | Products tested for the presence of hazardous chemicals | Chemical formulations tested for the presence of hazardous chemicals |

| Process permissions | Allows hazardous chemicals in manufacturing | Do not allow hazardous chemicals to enter the factory gate. |

| Tool | Tool used to adhere to regulatory requirements | Beyond compliance |

| Focus | Focus on end-of-pipe | Focus on input chemistry |

An important point to consider is that if hazardous chemicals are restricted at the factory gate before they even enter the manufacturing facility, theoretically they will not be present on the finished product. This means

The cost of product testing can be reduced significantly.

Fewer products to test and less transportation to testing labs save money.

Fewer garments need to be destroyed which is a requirement for testing.

Source of pollutants

| Restricted Substances in the Textile production process. | ||

| Process | Name of Restricted Substance | Details |

| Natural Fibre

Cultivation |

APEOs | Emulsifier & wetting agent in formulations of pesticide & insecticide. |

| Restricted Pesticides | The pesticide used to protect plant growth | |

| Heavy Metals (Arsenic) | Preservative,

Contaminant in input water |

|

| All Heavy Metals | Contaminants from soil | |

| Synthetic Fibre Production | Heavy Metals (Antimony) | Used as a catalyst in polyester manufacturing |

| APEOs | The emulsifier in spin finish, texturing oil | |

| Spinning | APEOs | Spin finish component |

| SCCPs | Waxing during yarn winding | |

| Sizing | Unreacted monomers | Acrylate based size |

| Pentachlorophenol | The preservative in size paste | |

| Knitting | APEOs | The emulsifier in Knitting oil and spotting oil |

| Desizing | APEOs | Wetting Agent |

| Pentachlorophenol | The preservative in size paste | |

| Isothiazolinone | Biocide in enzyme& size formulations | |

| Unreacted acrylate Monomer | From acrylate-based size | |

| Scouring & Bleaching | APEOs | Wetting agents, lubricants, de-aerating agents, scouring agents |

| Chlorinated Solvents | Stain removers | |

| Mercury | Impurity from caustic soda | |

| EDTA | Chelating agent | |

| Mercerization | Mercury | Impurity from caustic soda |

| APEOs | Surfactant and Wetting Agent | |

| Bio-polishing | Isothiazolinone | Preservative in enzymes |

| Dyeing processes | APEOs | Emulsifiers, Wetting Agents |

| Dyestuff formulations | SCCPs | De-dusting Oil |

| Washing process | APEOs | Washing–off chemicals |

| Reactive Dyeing | Banned Amines | Part of dyestuff |

| Formaldehyde | Dye- fixing agent | |

| Heavy Metals | Part of dyestuff | |

| Disperse Dyeing | Allergenic Disperse Dyes | Dyestuff |

| Phthalates | Leveling agents | |

| Chlorobenzenes | Carrier/Swelling Agent | |

| Acid Dyeing | Carcinogenic Dyes, Banned amines | Dyestuff |

| Basic Dyeing | Carcinogenic Dyes | Dyestuff |

| Metal Complex Dyeing | Heavy metals | Part of dyestuff |

| Direct Dyeing | Banned Amines | Part of dyestuff |

| Formaldehyde | Dye-fixing agent | |

| Carcinogenic Dyes | Dyestuff | |

| Pigment Dyeing | Heavy Metals | Part of Pigments |

| Formaldehyde | Fixer | |

| Unreacted Acrylate monomer | Binder in Pigment Dyeing | |

| Printing processes | APEOs | Emulsifiers, De-aerating Agents |

| Discharge Printing Process | Heavy Metals (Zinc, Nickel) | Part of Discharging Agent; printing screens, rollers |

| Formaldehyde | Discharging Agent | |

| All Printing processes | Unreacted Acrylamide Monomer | Binder |

| Natural Printing gums | Pentachlorophenol | The preservative used in ptg. Gums |

| Pigment printing | Formaldehyde | Dye Fixing agent |

| Washing process | APEOs | Washing-off Aids |

| Pigment Printing | Banned Amines | Part of a pigment |

| Heavy Metals (Lead, Cadmium,) | Part of a pigment, | |

| Phthalates | Plasticizer in PVC | |

| Diisocyanates | Binders based on PU or PVC | |

| Dibutyltin | Catalyst in PVC | |

| Reactive Printing | Banned Amines | Part of Dye-stuff |

| Heavy Metals | Part of Dye-stuff | |

| Plastisol Printing | Phthalates | Plasticizer |

| Dibutyltin | Stabilizer for PVC | |

| Silicone softener & fatty acid condensates & PE/ Paraffin wax | APEOs | Wetting Agents,

Emulsifiers |

| Dibutyltin | Catalyst in silicone finishing | |

| Easy care/Anti-crease/ Crease resistant | Formaldehyde | Cross-linking agent |

| Water, Oil & Stain-repellent Finishing | PFCs (PFOA/PFOS) | Water, Oil and Stain-Repellence |

| Fire-retardant | Chlorinated and Brominated Flame Retardants | Flame Retardant-finishing agent |

| Anti-microbial / Moth-proof Finishing | Tributyltin | Anti-microbial finishing Agent |

| Triclosan | Anti-microbial finishing Agent | |

| Antistatic Finishing | APEO | Emulsifier |

| PVA Emulsion | Phthalates | Stiff finish |

| Powder Coating | APEOs | Emulsifier |

| Benzene | Thickener | |

| Phthalates | Softener/plasticizer | |

| Acrylates | Softener/plasticizer | |

| Vinyl Chloride | Unreacted monomer | |

| PVC | Coating Material | |

| Polymer Dispersion Coating | Isocyanates | Polyurethane coating |

| Free Acrylamide | Unreacted monomer | |

| Acrylonitrile | Unreacted monomer | |

| Formaldehyde | Cross-linking Agent | |

| Solvent Based Coating | N-Methylpyrrolidone (NMP) | Solvent |

| Dimethyl Formamide (DMF) | Solvent | |

| N, N-Dimethyl Acetamide (DMAC) | Solvent | |

| Toluene | Solvent | |

| Tinting/Over dyeing | Heavy Metals | Part of Direct Dyes,

Reactive Dyes |

| APEC | Part of Reactive Dyes | |

| Garment Wash Effects | APEX | Soaping Agent, Lubricant |

| Stain Removal | Chlorinated Solvent | Stain Remover |

| Packaging and Transportation | Dimethyl Fumarate (DMF) | Biocide and Fumigant |

| PVC | Plastic Packaging Material | |

| Phthalates | Plasticizer in PVC wrapping | |

| Formaldehyde | Paper Packaging Material | |

| Heavy metals (Pb, Cd & Cr) | Cardboard manufacturing | |

The above list is guidance for the possible presence of restricted substances. One can study MSDS & TDS for the correct selection of chemicals & dyes in the process. Even chemical manufacturers can guide the selection of Dyes & chemicals for restricted substances.

MSDS

Let us understand important factors in MSDS

MSDS is a document generated by the manufacturer of chemicals.

A Material Safety Data Sheet (MSDS) is a document that contains information on the potential hazards (health, fire, reactivity, and environmental) and also gives information on how to work safely with the chemical product. It is a basic document for the development of a complete health and safety program. It also contains information on the use, storage, handling, and emergency procedures all related to the hazards of the material. The MSDS contains much more information about the material than the label. MSDSs are prepared by the supplier or manufacturer of the material. It is intended to tell what the hazards of the product are, how to use the product safely, what to expect if the recommendations are not followed, what to do if accidents occur, how to recognize symptoms of overexposure, and what to do if such incidents occur. There are 16 sections in standard MSDS & it can give complete information about hazards (Physical, Health & Environmental.

The standard format of Safety Data Sheets

MSDS should be provided in the official language of the country, where the substance is supplied.

There are total of 16 sections in MSDS & should be as under.

- Identification of the substance/mixture and the company/undertaking

- Hazards identification (assessment)

- Composition/information on ingredients

- First-aid measures

- Firefighting measures

- Accidental release measures

- Handling and storage

- Exposure controls / personal protection

- Physical and chemical properties

- Stability and reactivity

- Toxicological information

- Ecological information

- Disposal considerations

- Transport information

- Regulatory information

- Other information

This format is based on GHS recommendations and it is accepted throughout the world.

For sustainability, one must focus on hazard identification. The same is seen in section no. – 2, 10, 11, 12 & 13. No doubt section 15 is also important for hazard handling.

The impact of pollution is so high that, Government has laid down stricter norms for discharge of effluent & sludge (CPCB, SPCB) In addition to this, various NGOs, Brands, Buying houses are not allowing any industry to do business if they are polluting the atmosphere. The solution to the above issue is very simple & is known as CMS that is a Chemical Management System.

Author: Sanjay Harane