There are more Sustainable Alternatives

Bamboo fabric has been paraded as one of the Sustainable alternatives to ‘resource guzzling’ cotton or polyester – a ‘polluting’ petrochemical derivative. With fame came detractors, and soon we were made to realize that Bamboo fibre production process was indeed ‘unsustainable’.

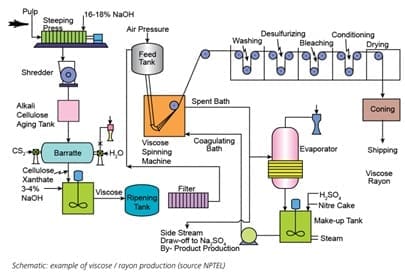

Growing of bamboo grass was pro-nature with incredible set of benefits like lower requirement of water, fertilizer, or pesticides, and sequesters a large amount of carbon dioxide, absorbing five times more carbon dioxide and releasing 35% more oxygen than similar plants. It’s also naturally regenerating, so harvesting bamboo still allows the plant to survive. However, the truth is that the process of converting this fibre present in bamboo stalks to fabric is ‘chemically toxic’ for our environment. The process involves dissolving the harvested bamboo stalks using strong chemical solvents like sodium hydroxide and carbon disulfide. This process is also known as hydrolysis alkalization which is combined with multi-phase bleaching.

In most of the factories, the revival of solvent is 50%. This means the other 50% is discarded into the environment. The production processes for bamboo and other regenerated fibres using hydrolysis alkalization is not considered sustainable or environment friendly because it poses severe health risks and pollutes the surrounding environment. This process is similar to the production of Rayon from wood chips and plant-based materials, and should be ideally called bamboo-rayon with no residual natural properties of bamboo.

The ideal ‘sustainable bamboo fibre’ can be achieved only through a mechanical extraction process that involves combing out the fibres and spinning these into threads, which is then called bamboo linen. This is labour-intensive and offers low production output. Given these inefficiencies, the cheaper alternative is the chemical-intensive alternative.

Another sustainable alternative of bamboo fibre production would be if ‘lycocell-process’ is adopted for bamboo. It’s made in a closed-loop cycle, so its chemicals and water are recycled and never released into the environment. Unfortunately such disclosures are not available for bamboo fabric used in garments.

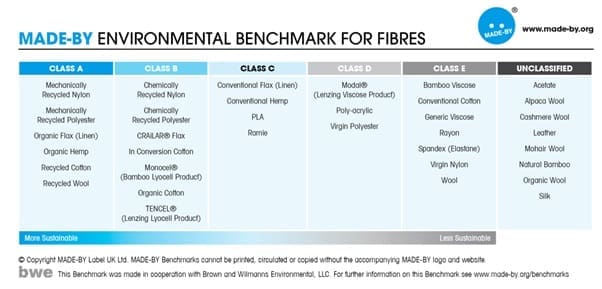

For the community of health-conscious consumers of Activewear, it has been a genuine desire to opt for clothing that is also ‘healthy’ for the environment. Many leading sports brands have championed the cause of recycled polyester and nylon by salvaging PET bottles, ocean plastic or fishing nets. Their branding efforts have created credible awareness among consumers, significant enough to command a 30 to 50 percent price premium for their recycled products. Its important to understand the spectrum of products along the sustainability scale to take an informed decision about choosing the right pair of Activewear.

It has become increasingly important to incorporate circularity in ‘production & consumption’ process. For the textile industry, these are understood as recycling of post-industrial waste and post-consumer waste. Few notable examples are ones like joint efforts by Invista and Nylstar to produce recycled nylon yarn from the post-industrial waste. Invista sources post-industrial nylon 6.6 material from its plant in Kingston, Canada, where fibres for airbags and carpets are produced. Through its proprietary process, Invista then converts post-industrial fibre waste to pellet form and supplies it to Nylstar for spinning, enabling some of the world’s top fashion houses to deliver sustainable garments to the market.

Lenzing has approached the post-consumer circularity concept through its proprietary REFIBRA™ technology; which involves upcycling a substantial proportion of cotton scraps e.g. from garment production, in addition to wood pulp, where the raw material is transformed to produce new virgin TENCEL™ Lyocell fibers to make fabrics and garments.

For Activewear, in addition to Tencel and Micromodal, few preferred sustainable fibres are reprocessed cotton like Cupro and Hemp. Cupro is a regenerated cellulose fibre derived from cotton linter. Cotton linter is the short downy fibre that enfolds the cotton seeds. The production process does not release anything into the environment using only clean water systems. Cupro is smooth, hypoallergenic, anti-static fabric with great resilience, especially in higher temperatures. The breathable fibre with micropores that quickly absorb moisture and release it to the outside making it a fantastic fabric to regulate body temperature by effectively reducing clinging and transporting moisture away from the skin, making it a perfect fabric for activewear with amazing technical properties.

Growing hemp is more sustainable than cotton and bamboo as it grows more densely, needing no pesticides or herbicides and returns almost 70% of the nutrients it takes back to the soil. The manufacturing process of hemp textile can be done organically through a mechanical process that requires no chemicals similar to the linen manufacturing. Hemp is naturally UV-protective and holds its shape because it stretches less than other natural fibres. It finds application in near-to-skin activewear which helps in sweat management, temperature regulation and also outerwear which requires higher rip-strength and UV protection at same time being soft & comfortable.

The emergence of Athleisure category has merged Activewear into the world of ‘fast-fashion’ due to broadened use of activewear garments and constantly changing trends, creating a huge environmental burden. Many brands have embraced responsible manufacturing by including ‘sustainable collections’ alongside their regular range of activewear. From a customer’s point of view, it is still difficult to identify an ethical brand, as many companies use sustainability as their advertising slogan or greenwashing. It’s a journey of realisation and taking corrective steps, the bigger responsibility lies with leading brands who have power to influence the entire value chain and communicate effectively to consumers.

Manoj John

CEO & Founder of WEARACTIV

WEARACTIV™ is a brand of Activewear designed with a purpose of enhancing the performance of users engaging in different types of sports or physical training / endurance / fitness activities.