Dr. M.S.Parmar, Maheshwar Singh, Nidhi Sisodia and Archana Singh

Northern India Textile Research Association

Sector-23, Rajnagar, Ghaziabad

Introduction:

The role of natural fibres is immense in the emerging “green” economy which

focuses on concern for the environment, the well-being of fibre producers & consumers, and the conditions of workers in the textile industry. During processing, they generate mainly organic wastes and leave residues that can be used to generate electricity or to make ecological housing material. And, at the end of their life cycle, they are 100% biodegradable.

Cornhusks show great potential in providing large quantities of natural cellulose fibres with significant economic benefits than any other agricultural by-product. The economic feasibility of developing cornhusk as an alternative to natural fibres also looks promising, especially when compared to the potential availability and production cost of other natural fibres. “Cornhusk fiber comes from nature, and completely returns to nature in the end” therefore cornhusk fiber is “the natural, green, and eco-friendly new-type textile fibre of 21st century”. However, these benefits cannot be realized unless cornhusk fibres are suitable for various applications, especially for textile materials. In India at present corn husk is mostly treated as a waste and burned to get rid of this. No systemic work has been done on this fibre in India. Keeping this challenge in mind an attempt has been made in this paper to extract corn husk fibres from corn husk and explore the possibility of its application in the textiles field.

NITRA Study:

Corn husk as shown in Fig 1, was collected from Aterna village in Panipat (Haryana). The fresh husk was medium-dark green in colour and soft in touch.

Fresh cornhusks Dried cornhusks

Fig. 1: Corn Husk fibre

The cornhusks were cleaned manually to remove any external impurities and rotten leaves and cut into lengths ranging 3-5 inches as shown in

Cleaning of cornhusks Cleaned cornhusks

Fig.2: Cleaned and cut cornhusks

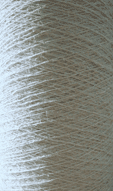

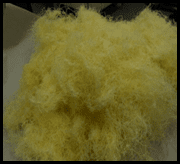

The corn husk was air dried at room temperature and stored in a properly ventilated room followed by alkali treatment to extract corn husk fibre as shown in

Fig. 3: Extracted corn husk fibre

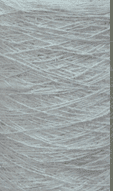

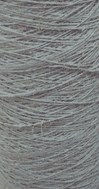

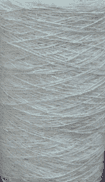

The extracted fibre was spun in to yarn by blending it with cotton, acrylic and polyester separately on various proportions (Fig. 4) and finally converted in to fabric using rapier loom. The complete cycle, from raw cornhusk to garment making is shown in the

Cornhusk/Cotton (30/70) Cornhusk/Polyester (30/70)

Cornhusk/Polyester (30/70) Cornhusk/Acrylic (30/70)

(Hand spun) (Ring spun)

Fig 4: Yarn samples from corn husk fibre

Fig 5: Cycle of converting waste cornhusk to Garments

The garments were designed and constructed using fabric developed out of various blends of corn husk is shown in the

Fig.: 6 Garments out of Corn Husk Fibre

ACKNOWLEDGEMENT:

Authors are thankful to Ministry of Textiles, Govt. of India for sponsoring this project.