CLOUD COMPUTING NEW TECHNOLOGY IN TEXTILE & APPAREL INDUSTRY

Since operating efficiencies are already high, participants of the garment and manufacturing supply chains must search for ways to boost margins other than lowering labour expenses. One of the most important aspects is collaboration with supply chain partners. Through greater capacity utilisation, lower reject rates, fewer charge-backs, and profitability, collaboration offers a way to cut costs in the supply chain in areas including product development, inventory management, and production. Collaboration enabled by information technology should be the primary focus for overcoming the hurdles. Collaboration among partners is becoming extremely crucial to make the supply chain more efficient.

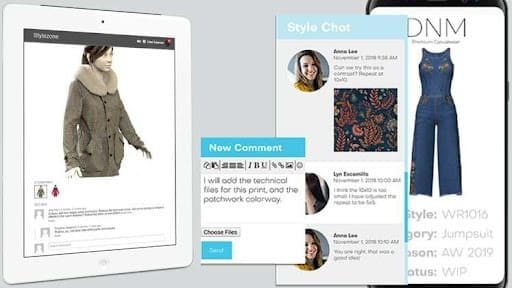

Cloud computing is a model for supplying on-demand, self-service computing resources with ubiquitous network connectivity, location-independent resource pooling, and quick flexibility that is enabled by information technology. Cloud computing is the next great trend that appears vague at first, but when measured in terms of the services it provides, it’s the most trendy and prominent computer system available over the internet. In the textile and garment industries, this computing system provides a variety of important services. There are certain unique management systems designed to make various company activities in the garment and textile and apparel industry easier.

What is Cloud Computing?

Cloud computing is a type of Internet-based computing in which shared resources, software, and information are sent to computers and other devices on demand, similar to electricity. Cloud computing is the method of storing, managing, and processing data via an Internet-based network of remote servers rather than a local server or a personal computer. People in favour of Cloud Computing believe that it helps businesses to reduce or eliminate upfront infrastructure costs.

Clothing, footwear, and accessory industries can profit from this technology in various ways. It allows you to set up a virtual office, providing access to your company from any location at any time. Access to your data has never been easier, thanks to the expanding number of web-enabled devices utilised in today’s work environment (e.g., smartphones and tablets).

Adaptation of Cloud Computing in Textile/Apparel/Fashion Industry

The textiles and garment industries can be considered as a supply chain made up of various distinct activities. The supply chain is rapidly being organised as an integrated production network, with each operation being positioned where it can add the most to the value of the end product, from sourcing raw materials to design and manufacture to distribution and marketing. Expenses, quality, delivery reliability, access to quality inputs, and transportation and transaction costs are all key factors to consider when deciding where each activity should be located.

Supply Chain Management

Supply chain management is a collaborative process and project management approach to efficiently and effectively meet the needs of the end customer. Collaboration is one of the most important aspects of successful supply chain management. It’s worth mentioning that there are three types of flows that happen in supply chains:

- Product returns, servicing, and recycling are all examples of material flows, which represent product flows from suppliers.

- Order transmission and tracing are represented by information flows, which coordinate the physical flows.

- Credit terms, payment schedules, consignment, title ownership agreements, and everything else related to finance are all represented by financial flows.

Three essential pillars support these flows: processes, which combine the firm’s logistics, new product development, and knowledge management capabilities. Organizational structures, which encompass a wide range of interactions ranging from total vertical integration to networked companies, as well as management styles, performance evaluation, and reward schemes. Enabling technologies, which comprise both process and information technology, are essential for supply chain management in any firm.

Supply Chain Management in Textile/Apparel/Garment Industry

In the textile and garment industry, the supply chain begins with the consumer and ends with the product. In many situations, information can also be seen to flow directly from retailers to textile manufacturers. Textiles are manufactured for use in the apparel industry as well as in the home. When decisions are made on different areas such as patterns, colours, and material, there is direct and unambiguous communication between retailers and textile mills in the former instance. Textile industries also supply household appliances directly to the retailers in the second example. Since the Indian Apparel and Textile Industry is one of the largest sources of foreign exchange flow into the country, with apparel exports accounting for nearly 21% of total exports, and also because textile is one of the largest sectors, cloud computing can help it grow faster and survive in this competitive world.

Many businesses still use conventional means of communication and other procedures nowadays. For companies in the apparel industry, cloud computing is the ideal solution. As more companies and retailers embrace cloud technology, it is gradually being recognized as an efficient solution for managing global supply chain in the garment industry.

Benefits of Cloud Computing in Textile and Apparel Industry

Cloud computing has numerous advantages in the textile and apparel sector. Any disruptions in any process are always communicated to a brand. It could be a delay in obtaining raw materials or at the production level, or a delay in transportation, etc. The brand is quickly notified thanks to cloud technology, and they have plenty of time to make the best decision possible in order to deliver the complete order on time.

Quick payments are yet another advantage of cloud computing. A renowned footwear firm uses this technology to approve payments in as little as 48 hours, with no paperwork required. An international clothing brand employs cloud applications to notify consumers about the discount they received for making early payments, which reduces the duty on payments. In exchange, the brand receives discount from its suppliers if payment is received within 5 days of delivery. In addition, the brand pays less duty on the invoice value. As a result, both parties benefit from the scenario.

Conclusion

Coordinating with all parties at all times is a difficult task. If traditional procedures are followed, they will result in inefficiency and will take time. Furthermore, a typical sourcing business agreement involves 5-15 parties. They are also from various nations, have different time zones, and speak different languages. Using cloud technology, however, it is possible to communicate and collaborate with all parties at the same time. As a result, if adequate planning, technology, and operations are carried out, cloud computing can be a true lifesaver.

With unusual consumer demands, different trading partners, and other factors, the textile and garment sector is unpredictable. Since customer expectations are already high, apparel and manufacturing supply chain partners must adopt other approaches in addition to lowering labour costs and sustaining profits. Cloud computing is an ideal solution for apparel industry to achieve supply chain coordination.

Source: Textile Learner

References:

Featured image: Tukatech.com

https://textilelearner.net/cloud-computing-in-textile-and-apparel-industry/

https://www.fibre2fashion.com/industry-article/6906/cloud-computing-in-textiles

https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.403.3659&rep=rep1&type=pdf

https://www.apparelsearch.com/terms/c/cloud_computing.html

Author:

Somasree Roy