Dr N.N.Mahapatra

B.Sc( Hons),B.Sc (Tech )(Bom)M.Sc ( Chem ),Ph.D ( Chem ),M.B.A( IMM,Cal)

C.Col FSDC ( UK),CText FTI ( Manchester ),Int Trg ( Australia)),Sen Mem ,AATCC (USA),FAIC(USA)

FIC ,FTA , FICS,FIE,FIIChE ,MISTE ( INDIA)

President

COLORANT LTD, Plot No. 116, Phase II Near Ambica Cross Road G.I.D.C.Vatva,

Ahmedabad-382445

We all know that 2009 is named as the YEAR OF NATURAL FIBRES . It may be vegetable fibre or animal fibre. The use of various type of natural fibre in spinning of synthetic or worsted yarn was at the peak from 1980 to 1990 . We all know during this decade Jayashree Textiles ( a unit of Aditya Birla group ) situated in Rishra , Dist Hooghly ( West Bengal) was the main manufacturer of Poly/wool blends with Ramie, Flax, Hemp, Silk ,Camel hair, Angora, Mohair , Pineapple etc under the able guidance of Mr Jayant Shroff , Mr Badal Das , Mr R.N.Chatterjee and Mr Govind Rathi . During this period the author had a chance to work with the above pioneer people of fancy worsted yarn production in India.

Almost during the same period the use of various type of natural fibres was used in Poly/viscose synthetic spinning at Gujarat Spinners Ltd situated in Amletha, Rajpipla, Gujarat under the able guidance of Mr Asis Bagrodia, Mr B.K.Ametha, Mr J.S.Anand , Mr S.K.Bhatia and Mr P.K.Choudhury . The fibres used were Flax , Jute, Silk, Mohair , Ramie etc. During this period the author had a chance to work with the above pioneer people of fancy synthetic yarn production in India. All the above fancy yarns were used in making fabrics like suiting, shirting and dress materials like Gwalior Suitings, Raymonds, Digjam , Vimal Suitings, Dinesh etc.

Although wool is by far the most important animal fibre , there are a number of hair fibres which are of considerable commercial value . These come mostly from animals of the goat and camel families . Mohair comes from Angora goat , one of the oldest animals known to man . Mohair is only produced by Angora goats .Mohair is considered a luxury fibre because it is a silky material and should not be confused with Angora fibres which come from Angora rabbits . And cashmere ,which is a softer fibre obtained from another species of goat . Until early in the nineteenth century ,Turkey was almost the sole producer of mohair .As the manufacture of textiles expanded during the period of the Industrial Revolution ,efforts were made to raise the Angora goat in other parts of the world. The Angora goat , which originated in Turkey ,has a coat of long, lustrous hair which provides the textile fibre known as mohair .Much of the world’s production of mohair is in Turkey ,South Africa and the USA. Mohair is the hair of the Angora goat , native to the province of Angora ,Turkey . This species of goat is now raised in South Africa and the United States ,principally in Oregon, California , and Texas . The U.S. is now the chief producing country and also the biggest consumer of mohair .Some domestic mohair ,particularly the mohair obtained from Texas ,is of excellent quality .

Imported mohair is long staple ,9 to 12 inches ( 230-300 mm)long and allowed a full year ‘s growth before shearing . Mohair is as warm as wool although it is much lighter in weight making it ideal for traveling. Mohair is also desirable due to its warmth ,durability and beauty and has been used to make garments for kings ,sultans and as part of the tabernacle in the bible .

Production –

The domestic goat is shorn twice a year ,yielding a shorter staple ,from 8 to 10 inches ( 200 -250 mm) .They are usually clipped twice a year ,providing about 1.8 – 2.3 kg ( 4-5 lb) of mohair per animal at each clip. Good quality mohair goats will produce 10-20 pounds of mohair per year in two shearings yielding staple lengths of 4-6 inches .Imported mohair can be spun to fineness of Ne 60 in yarn count. The highest count possible for domestic fibre is Ne 40 .The domestic fibre has a great amount of coarse ,stiff hair ,known as kemp ,which does not process readily or allow thorough penetration of dye. Quality mohair comes in two basic styles , a ringlet shaped lock with bundles of fibres togother and flat wavy locks. Most animals will also have some kemp or medulated fibres . Kemp fibres have a hollow core ,are coarser and shorter than the mohair lock and will stick out of the yarn and make a garment feel scratchy .These fibres are the “guard hairs “ that exist to help protect the animal from the weather .Angora goat breeders work hard to breed this out of their stock. This may be why most Angora goats don’t like being in the rain. With little or no guard hairs they can get wet to the skin and need shelter from the rain especially if it is cold . Medulated fibres tend to be as long as the mohair and still have some hollow characteristics but are not considered to be as big of a problem as kemp. Therefore the quality of the fibre varies ,depending on its source and the conditions under which the goat has lived . Fleeces are graded into three types as below.

- Tight lock – It is characterized by its ringlets and is usually very fine .

- Flat lock – It is wavy and of medium quality .

- Fluffy or open fleece – It is the least valuable.

As in the case of wool ,mohair contains the dead ,dull fibres that are known as kemps. The fibres vary in length ,depending upon the age of the goat . Mohair is typically sold in three grades .These grades are also used as classes in fleece competition judging .

- Kid – Finest of all grades .It can be in the 19-20 micron range .Usually the first and second shearings from the Angora goat are kid grade . At six months ,an Angora kid will provide fibres 10-15 cm (4-6 in ) long

- Yearly – Fine to medium .Usually the 3 rd and 4 th shearings from the goat although some animals will remain fine past this point and is considered fine adult . At twelve months ,they will be 23-30 cm (9-12 in ) The goat will be less than 2 years old.

- Adult – While the Angora goat is not considered to be a full adult until 4 years old ,adult fleece is generally considered to be any fleece from a goat more than 2 yers old . The fibre can be fine ,medium or “strong “ depending on the quality and age of the animal.

The surface of a mohair fibre has some resemblance to that of wool .It is covered with epidermal scales which are anchored much more closely to the body of the fibre than are wool scales.There are only about half as many scales as there are on wool.Mohair has some 5-6 scales per 100 microns length of fibre ,whereas fine wool will have about 11 .

Properties of mohair fibre –

It is two – and – a –half times as strong as wool and outwears it . Unlike sheep’s wool ,it is not curly .It is stronger than wool and produces hardwearing fabrics. Mohair resemble wool in being covered with epithelial scales and in consisting of keratin .But the scales are more smoothly arranged and so mohair do not felt readily as does wool fibre . Mohair has a circular cross-section. It is a smooth ,strong and resilent fibre . It doesnot attract or hold dirt particles. Mohair fibre is more uniform in diameter than wool fibre. It does not shrink or felt as readily as wool.

Mohair is almost non-flammable .When placed under ,or near ,a naked flame ,it tends to shrivel into a bead like ash. Once taken away from the flame ,burning stops instantaneously . Early Teddy Bears were made from mohair because of this property and because there is less allergic reaction to mohair than wool . Mohair can be twisted or bend without damaging the fibre .This is due to its structure which established it is the most durable of all animal fibres.

Mohair will stretch an average 30 % over its length and then will be able to spring back into shape. Due to this property ,mohair garments resist wrinkling ,stretching or sagging during wear. Mohair possesses great strength . Diameter to diameter ,it is stronger than steel. Mohair fabrics are wrinkle –resistant and do not mat readily because of the natural resailiency of the fibre.

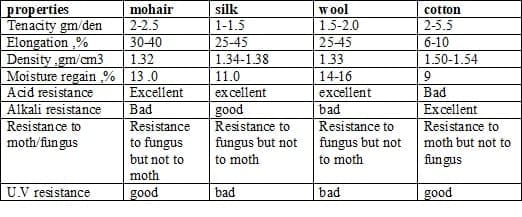

Comparison of properties of mohair fibre :

Blending of mohair fibres –

It is very difficult to spin 100 % yarn. So it is mixed with other fibres to make warm ,lightweight fabrics . The hair can be used for knitting yarn. Vardhman and Oswal Industries mix mohair with Acrylic fibre by 10-15 % and make knitting yarn which is used for making sweaters, cardigans etc. Thick ,spongy ,open fabric ,in plain weave ,with a very hairy texture .Its composition is usually 70 % mohair and 30 % wool .

Dyeing and finishing of mohair fibre –

Like wool ,mohair is contaminated with natural grease ,dirt and vegetable impurities .These may account for as much as one-third of the weight of the raw fibre .The clean ,scoured fibre is usually white and silky.

Acid dyes and Metal complex dyes are used for dyeing of mohair fibres. It absorbs dye evenly and permanently. It dyes well and has an attractive lustre .The lustre of mohair is one of the most important characterstics .Lustre is the natural sheen of the fibre caused by light being reflected more directly by the larger outer scales of the fibre . This lustre or sheen helps dyed mohair resist fading caused by time and the elements and makes it very hard wearing.

Different types of functional finishes are given to the mohair fabrics. One of them is it is made mothproof.

Uses of mohair fibre –

Uses include fancy goods ,felt hats ,linings , plushes and in blended yarn ‘s for use in men’s and women ‘s suiting fabrics . It is very expensive . Mohair can be combined with worsted yarn ,or woven alone ,to produce a very lightweight ,shiny ,attractive suiting fabric . It is used for men’s lightweight suits, dinner jackets etc. The mohar /wool blended fabric is bulky and can be used for warm ,lightweight lined coats ,but is best for simple wrap-overjackets,sleeveless waistcoats ,etc , which are unlined ,and is excellent for shawls and stoles .It is soft and may ‘seat’ .Mohair is used to a considerable extent for making plush fabrics.

Mohair is characterized by its remarkable resistance to wear .Mohair fabrics are therefore used wherever durability is the first essential. Upholstery in public vehicles ,car hoods ,etc are often made from mohair where resistance to wear and tear can be combined with attractiveness .

In combination with wool ,mohair is often used for summer suitings . It is made into all manner of dress materials , plushes and astrakhans .

Acknowledgement – The author is thankful to Mr Subhash Bhargava FSDC ( UK),MD,Colorant Ltd ,Ahmedabad for giving permission to publish this article.