CAUSTIC CIRCULARITY A GAME CHANGER FOR THE TEXTILE INDUSTRY

Caustic circularity is not only environmentally beneficial; it will also improve the textile industry’s competitiveness. Caustic circularity can be a game changer for the industry!

Application of caustic soda in Textile Industry and its Impact on fabric

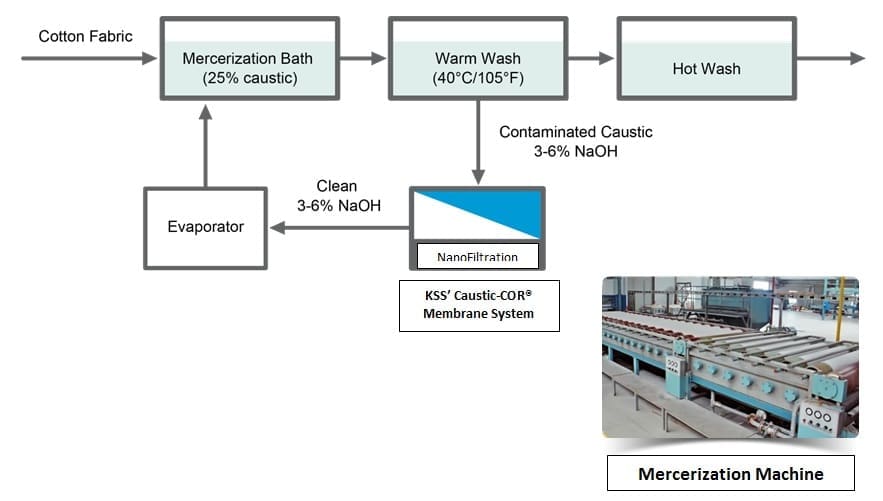

- Mercerization of Cotton Fabric

Enhanced dye affinity

Improved fibre strength

Enhanced air permeability

Better Lustre

Enhanced colour fastness

Enhanced shrinkage resistance

- Scouring & Bleaching of Fabric

Removes impurities (natural & added) such as oils, fats, waxes, proteins, and pectin. Removes added impurities during sizing, and gives proper whiteness to product, and makes it highly absorbent for next process.

Recent Trends in Textile Processing

- Spent caustic is rarely recycled in majority of the textile processing facilities due to the heavy impurities / contaminants.

- Spent caustic (wash liquor) is usually sent to the mill wastewater treatment plant or sold outside agencies at nominal price. This can be used either to generate NaOCl or purified and concentrated for recycle.

- In general, when wash liquor is sent to ETP, it has higher pH which is neutralized by hydrochloric or sulphuric acid, resulting in increased cost of operation and TDS of effluent being discharged after treatment.

- When spent caustic is sent to conventional CRP, plant technicians are not willing to reuse for processing of costly raw material due to impurities present in recovered caustic.

- Operating cost (steam, power and scaling -down) of conventional CRP is very high.

Impurities Present in Spent Caustic

- Dissolved chemicals / sizing chemicals (during mercerizing of material at Grieg / half bleached stage)

- Dyestuff (while dyed material is mercerized)

- Cotton lint

- Pectin

- Oils, Fats & Waxes

- Hemi-cellulose

- Gassing dust from singed fabric

- Metals from machines and pipelines

- Various metals from machines and pipelines

In short, recycling of caustic is not appreciated for quality product because of:

- Quality of recycled caustic

- Cost of recycling and treatment at ETP

- Adverse impact on end product

In order to resolve this issue, S.A. Pharmachem’s technical team has taken several trials and ultimately developed a full proof process for recycling of caustic. This new development is known as “Caustic Purification System”.

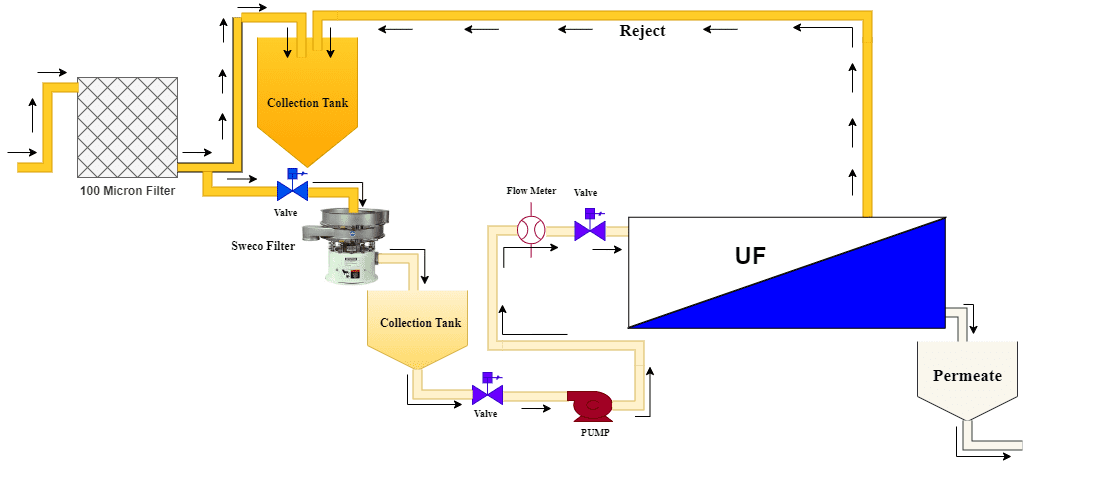

Caustic Purification System (CPS)

Caustic purification system is designed specifically to recover, purify and reuse caustic from various industrial applications.

Practical Experiences Using SelRO® Membrane

- >90% recovery

- Reduction in total suspended solids around 49%.(at ETP primary collection tank)

- Reduction in total dissolved solids around 9%(at ETP primary collection tank)

- Reduction in COD around 55 %(at ETP primary collection tank)

- Reduction in turbidity around 99% (recovered caustic is colourless & crystal clear)

- Reduction in iron content around 45% (recovered caustic stage while compared to conventional CRP)

- Compact design (required low space for installation)

- Payback < 2 years (enjoy with quality of end product)

Process advantages of Caustic Purification System

- As the purified Caustic is free of impurities, it improves Caustic Recovery Plant overall efficiency.

- It reduces steam consumption of CRP,

- It reduces scaling inside CRP (less damage to equipment),

- It reduces the cleaning frequency of CRP unit.

- Lower frequency of cleaning of CRP, reducing downtime of the CRP unit.

- It reduces acid consumption (required for neutralization at ETP)

- It reduces load on ETP (TDS, TSS & COD).

- Strength of purified caustic remains ~ same as feed.

Pilot Plant is available for techno commercial studies on request.

Please contact: Vinay D Patil, Director, S. A. Pharmachem, [email protected] , +91-9820098742