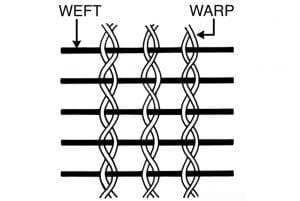

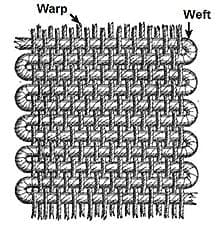

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft or filling. (Weft is an old English word meaning “that which is woven”; compare leave and left.) The method in which these threads are inter-woven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band which meets this definition of cloth (warp threads with a weft thread winding between) can also be made using other methods, including tablet weaving, back strap loom, or other techniques without looms.

The way the warp and filling threads interlace with each other is called the weave. The majority of woven products are created with one of three basic weaves: plain weave, satin weave, or twill. Woven cloth can be plain (in one colour or a simple pattern), or can be woven in decorative or artistic design.

History

Weaving is technique of fabric production. It consists of intertwining of two separate yarns or threads at right angles to form a fabric or cloth. Those two threads are called warp and the weft. Fabric is usually woven on a loom which is a device that holds the warp threads in place while weft is woven through them. There are also other methods of weaving. The method where the warp and weft interlace with each other is called the weave. The basic types of weave are plain weave, satin weave and twill which give different patterns and textures of fabrics for different uses.

Humans know about weaving since Paleolithic era. Flax weavings are found in Fayum, Egypt, dating from around 5000 BC. First popular fiber in ancient Egypt was flax, which was replaced by wool around 2000 BC. By the beginning of counting the time weaving was known in all the great civilizations. Early looms need one or two persons to work on them. Bible refers to loom and weaving in many places.

By 700 AD, horizontal and vertical looms could be found in Asia, Africa and Europe. At that time also appeared pit-treadle loom with pedals for operating heddles. That kind of loom first appeared in Syria, Iran and Islamic parts of East Africa. Faithful were required by Islam to be covered from neck to ankle which increased the demand for cloth. In Africa, the rich wore cotton clothing while the poorer had to wear wool. By 1177, loom was improved in Moorish Spain with rising higher above the ground on a stronger frame. Now the weaver’s hands were free to pass the shuttle, while operating the heddles was done by the feet. This type of loom became the standard European loom. In Medieval Europe, weaving was done at home and sold at fairs. The craft spread and the guilds were established. Wars, famine and plague shifted manufacturing of fabrics from home to purpose-built centralized buildings.

Colonial America relied on Great Britain for manufactured goods so they began to weave cloth from locally produced fibers. Cotton and wool was mostly used but because of the labor-intensive process to separate the seeds from the cotton fiber, wool was used more. That changed with the invention of the cotton gin, a machine that quickly and easily separates cotton fibers from their seeds. Flax and hemp were also used as a material for fabrics. Plain weave was preferred at the time with decorations woven into the fabric or wood block printing.

Industrial revolution switched weaving from hand to machine. John Kay invented the flying shuttle in 1733 and enabled weaving of wider fabric as well as made it faster. The first factories for weaving were built in 1785. Jacquard loom was invented in about 1803. It could be programmed with punch cards which enabled faster weaving of more complicated patterns. White fabrics were printed mechanically with natural dyes at first with synthetic dyes coming in the second half of the 19th century.

The weaving process

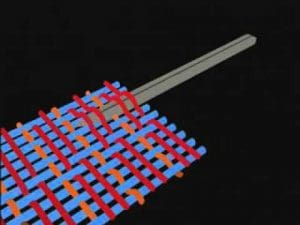

Woven cloth is normally much longer in one direction than the other. The lengthwise threads are called the warp, and the other threads, which are combined with the warp and lie widthwise, are called the weft (synonyms are “filling,” “woof,” and “shoot,” or “shute”). An individual thread from the warp, of indefinite length, is called an end; each individual length of weft, extending from one edge of the cloth to the other, is called a pick, or shot. Consecutive picks are usually consecutive lengths of one piece of weft yarn that is repeatedly folded back on itself.

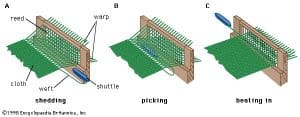

In all methods of weaving cloth (except the rudimentary form of darning), before a length of weft is inserted in the warp, the warp is separated, over a short length extending from the cloth already formed, into two sheets. The process is called shedding and the space between the sheets the shed. A pick of weft is then laid between the two sheets of warp, in the operation known as picking. A new shed is then formed in accordance with the desired weave structure, with some or all of the ends in each sheet moving over to the position previously occupied by the other sheet. In this way the weft is clasped between two layers of warp.

source: https://www.britannica.com/topic/textile/The-weaving-process

Since it is not possible to lay the weft close to the junction of the warp and the cloth already woven, a further operation called beating in, or beating up, is necessary to push the pick to the desired distance away from the last one inserted previously. Although beating in usually takes place while the shed is changing, it is normally completed before the new shed is fully formed.

The sequence of primary operations in one weaving cycle is thus shedding, picking, and beating in. At the end of the cycle the geometrical relation of the pick to the warp is the same as it would have been if the pick had been threaded through the spaces between alternate ends, first from one side of the cloth and then from the other, as in darning. This is the reason the weaving process is considered an interlacing method.

Types of Weaves

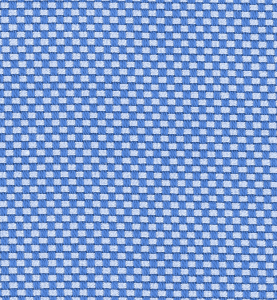

1 Plain weave

source: https://textilelearner.blogspot.com/2011/03/definition-and-characteristics-of-plain_4390.html

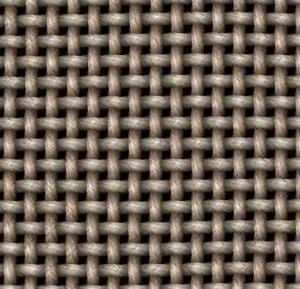

This is a weave with the most simple interlacing but it makes for a very strong and firm fabric because these interlacings are more frequent than for any other weave.

In this weave, the warp thread is interlaced over the weft thread by alternately lifting and lowering of the yarns. ie each and every weft thread goes under and over the warp threads across the width of the fabric. The advantage of this weave is that it is quite strong and durable and produces very fine good quality fabrics.

It is also called tabby weave or taffeta weave or linen weave.Also called Panama weave.

source: https://sewguide.com/fabric-weaving-types/

Hopsack is a plain weave with two or more threads in weft and warp interlaced instead of one. Also called Celtic weave

Percale is a type of plain weave which produces a very smooth high thread count fabric by the same name.

Poplin weave is an unbalanced plain weave in which two weft-threads and one warp-thread of the same colour cross each other. As weft threads are more than the warp thread there is a ridge on the weft thread creating a ribbed weave. In this weave cotton polyester and nylon fibers are used.

In most of the plain weave fabrics the weft thread and the warp thread are of the same colour resulting in an even coloured fabric but for some fabrics like end-on-end poplin and cambric the weft thread will be white or some other colour while the warp thread will be coloured – this results in a subtle shade of the colour.

Fabrics with a plain weave: About half of the woven fabrics are in this weave. It includes most of the different types of cotton like muslin, organdy, canvas; linen, rayon, silk, Chiffon, organza, voile, wool, crepe and a whole lot of other fabrics

2 Rib weave

https://www.koofers.com/flashcards/fm-exam-3/review

A variation of the plain weave. Here, either weft yarn or warp yarn is woven raised because it is a thicker yarn ie the warp and weft yarns are of different weights. Usually, it is the weft yarn which is thicker in which case there is an appearance of prominent ribs in the horizontal direction.

source: https://sewguide.com/fabric-weaving-types/

Fabrics with a rib weave : Broadcloth, Faille, Poplin, grosgrain

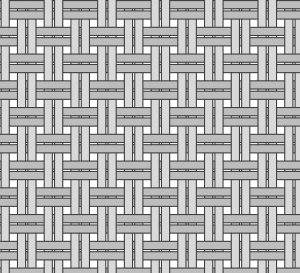

3 Basket weave

source: https://www.stonecenteronline.com/carrara-white-diagonal-basket-weave-stanza-black-dots-marble-mosaic-tile-polished

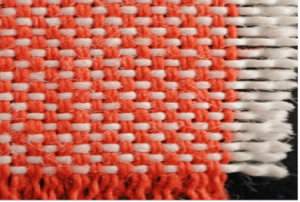

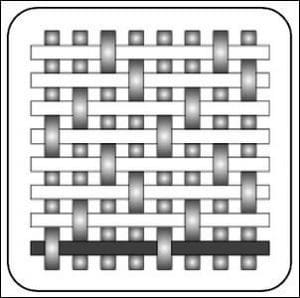

This is a variation of the plain weave but with more than one thread. Two or more warp fibers alternately interlace with two or more weft fibers. Instead of the over under pattern in a plain weave we have a over over under under pattern.

The resultant fabric has a matt weave and flexibility and a looser construction. It is not as durable as plain weave, though and may shrink in the wash. It is difficult to sew. Another name is a hopsack weave

source: https://sewguide.com/fabric-weaving-types/

Fabric with this weave: Canvas, Duck cloth, Monk’s cloth.

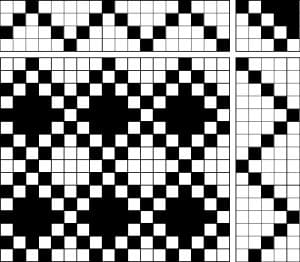

4 Twill Weave

source: https://ya-webdesign.com/image/weaving-drawing-plain-weave/1565249.html

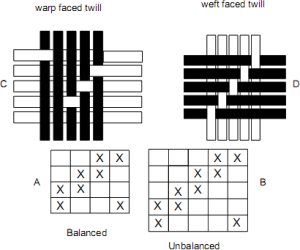

In this weave, one or more warp fibers alternately weave over and under two or more weft fibers repeatedly (Weft-faced)or one or more weft fibers alternately weave over and under two or more warp fibers repeatedly (warp-faced). This results in a strong and soft fabric which has more drape than all other weaves with a self-design effect, with parallel diagonal ribs formed left-to-right or right-to-left but the fabric has a smooth surface.

There are clear diagonal lines on the surface of the fabric. The back side of this weave is rough and will show the opposite pattern of the front. Fabrics with twill weave are more durable, heavy and wrinkle resistant than ones with plain weave

In denim, inarguably the most famous twill fabric, the weft-thread is white or off-white and the warp-thread is indigo-dyed.

source: https://sewguide.com/fabric-weaving-types/

Fabrics with Twill weave: Denim, flannel, Velvet, Drill, Jersey, Gabardine etc has this weave.

Twills have a wale. Wales can be S or Z. If the wales run from upper right to lower left the weave is called right-hand twill / z twill;

If the wales run from upper left to lower right the weave is called left hand twill / s twill. When there is a combination of right-hand and left hand twill it is called a broken twill

Variations : One and one (Pick & Pick) has light and dark warp and weft. 3 by 1 twill has three threads crossing over one weft thread. This is a common denim weave. 2 by 1 twill has two warp thread crossing over one weft thread.

Gabardine is a fine steeply set twill weave. Cavalry twill is a slightly broader steeply set twill; Whipcord is another bold and steep twill. Diagonal twill has a pronounced diagonal twill weave. Double diagonal twill weave has two or three differently wide and bold twill lines.

Twilled hopsack weave looks as if twill is running both left and right. Pinhead has one ligt and one dark warp and a solid dark weft. Barleycorn is a twill way arranged to look like barley corn.Pepper and salt is a variation of the one and one with highly contrasted twist in the warp and weft.

5 Herringbone weave

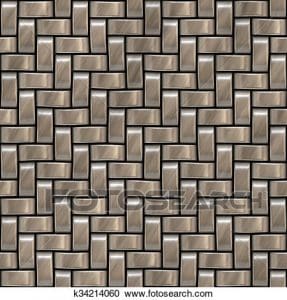

source: https://www.fotosearch.com/CSP035/k34214060/

This refers to a broken twill weave which gives a herringbone (zig zag) pattern with right and left twills appearing alternatively side by side , both having the same width.

The herringbone weave is also called feather twill or arrowhead twill. Other than the attractiveness of its design it has all the qualities of a twill weave. This is similar to other broken twill designs like the chevron pattern

source: https://sewguide.com/fabric-weaving-types/

Shell weave has a combination of right and left-hand twills – looks like a shell

Corkscrew weave has the herringbone pattern but at a very low angle.

Fabric with the herringbone weave: Tweed

6 Satin weave

source: https://in.pinterest.com/pin/404338872766732849/

This is a variation of the twill weave but with continuous warp yarn, with as few interruptions of weft as possible ie it has fewer intersections of warp and weft threads – weft yarns are floated over warp yarns, which results in a smooth and shiny surface.

The fibers used are filament fibers like silk or nylon. The fabric in this woven pattern will be very smooth and lustrous and has a flexible structure, because of the long floats. The greatest luster will be in the lengthwise direction.

source: https://sewguide.com/fabric-weaving-types/

The disadvantage is that the fabric fibers will easily snag so this weave is not considered as strong as the other weaves.The advantage of this weave is its own disadvantage – it is the long floating yarns that snag.

Fabrics with this weave: Many types of satin fabric like peau de soi, charmeuse.

7 Sateen weave

This is a satin weave with short staple yarns like cotton. The floats will be in the weft direction ie continuous weft yarn, with as few interruptions of warp as possible. The fabric is not as lustrous as the satin weave fabric but they are more durable.

source: https://sewguide.com/fabric-weaving-types/

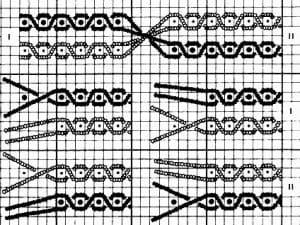

8 Leno weave

source: https://www.heddels.com/2017/12/7-weave-patterns-to-know-twill-basketweave-satin-and-more/

In this weave, wrap yarns do not lie parallel to each other as in other weaves; the adjacent warp fibers (two or more) are twisted around consecutive weft fibers (one or more)to form a spiral pair (figure 8). It results in a sheer open weave fabric which is at the same time strong. It is also called gauze weave

source: https://sewguide.com/fabric-weaving-types/

Fabrics with Leno weave : Gauze, net, tulle.

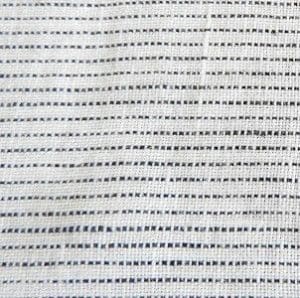

9 Oxford Weave

source: https://www.oldbullshorts.com/oxford-weave

In this two, thin warp yarns are woven to each very soft, thicker yarn in the weft direction. This results in the thin warp yarns to break leaving holes. The resultant fabric is very fine and soft. In a similar Pinpoint weave weft-thread alternatively pass over and under two warp-threads.

source: https://www.oldbullshorts.com/royal-oxford-weave

Fabrics with oxford weave : Oxford cloth, shirting.

10 Bedford cord weave

source: https://www.youtube.com/watch?v=3ioFV51c9BQ

This is a characteristic weave found in the fabric Bedford cord with lengthwise ridges. The weave has prominent lengthwise ribs with sunken lines in between. This is a combination of a plain weave and whipcord twill weave. Wadding threads are introduced in this weaving to bring more prominence to the cords.

source: https://sewguide.com/fabric-weaving-types/

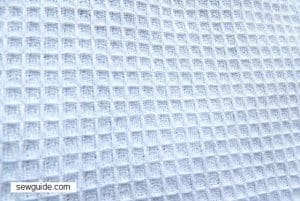

11 Waffle Weave

source: https://www.gistyarn.com/blogs/journal/waffle-weave-lap-blanket

This is also called honeycomb weave because of the pattern it creates on the face of the fabric. The warp and weft threads are interlaced and floated in a manner that produces a regular pattern of small square ridges and hollows in the fabric. This weave has a 3D effect but makes for a rough surface because of the raised areas on the face of the fabric. The shapes formed on the fabric surface maybe square or diamond.

source: https://sewguide.com/fabric-weaving-types/

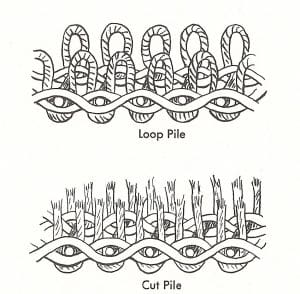

12 Pile weave

http://artquill.blogspot.com/2017/09/woven-pile-fabrics1-art-resource-marie.html

This is a weave that is used to make a soft pile fabric which is very absorbent and insulating . You will find cut/uncut piles on one side or either side of the fabric as a result of this weaving. The uncut or loop piles has loops

on the face and back of the fabric. Ground yarns and additional yarns for the pile are used in the fabric construction

source: https://sewguide.com/fabric-weaving-types/

Fabrics with a pile weave: Velvet (Cut pile), terrycloth , Corduroy, Velveteen (Uncut/loop pile).

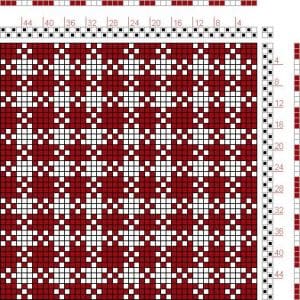

13 Jacquard weave

source: https://www.fashion-era.com/fashion_fabrics/fabrics_jacquard_brocade_damask.htm

This is a beautiful weave with intricate and colourful designs woven into the fabric. This weave is produced on a jacquard loom.

The weave results in a fabric which is strong and lustrous and has a luxurious look and feel. Jacquards can be made one color or a mix of colors and can be used to create simple as well as complex patterns. Often the back side of a jacquard is the mirror image of the pattern on the front. The weave is named after the Frenchman Joseph Marie Jacquard who invented the jacquard loom.

source: https://sewguide.com/fabric-weaving-types/

Fabrics with this fabric weave : Brocade, Damask, Brocatelle, Matelasse are fabrics with this weave and these fabrics are typically used for bedding, upholstery, draperies etc.

14 Dobby weave

source: https://in.pinterest.com/pin/AbCYje4o2p2mIvL9lLX8mPCUx_oTBVdeK1I_y47oxVmqeZu5UwTMpAY/

This is a patterned plain weave with small designs/geometric patterns. You need special dobby machines to create this weave. The machine selectively raises some warp threads and selectively depresses others with the help of a dobby card. The fabric which is woven this way is comparatively flat and fine.

source: https://sewguide.com/fabric-weaving-types/

Fabric with Dobby weave : Moss crepe.

15 Crepe weave

source: https://www.youtube.com/watch?v=K41T_M1jGTQ

A type of weave that results in a broken irregular pebbled appearance by the use of high twist yarns and a special method of weaving.

source: https://sewguide.com/fabric-weaving-types/

Fabric with this weave : Crepe fabric

16 Lappet weave

source: http://texpedia.org/blog/2013/09/21/woven-fabric-patterns/kilim_weaving_technique_6/

Lappet weave is a method of creating machine-made embroidery-like figures on a fabric ground, by introducing warp threads. Swivel weave a similar weave in which weft threads are introduced. It is very similar to how embroidery is done.

source: https://sewguide.com/fabric-weaving-types/

17 Tapestry Weave

source: https://en.wikipedia.org/wiki/Weaving

This is also done by the jacquard loom but it is mostly based on handlooming techniques and has very elaborate designs made usually of a single repeat. The complex designs characterized by numerous colour changes are formed by weft yarns and warp yarns. It is used interchangeably with jacquard weave. You will find wall hangings and flatweave rugs made in this technique.

source: https://sewguide.com/fabric-weaving-types/

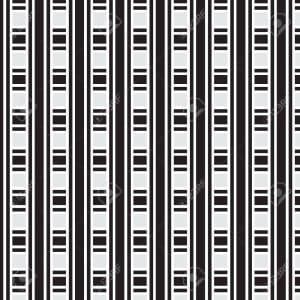

18 Striped weaves

source: https://www.123rf.com/photo_83486490_stock-vector-black-and-white-thick-and-thin-striped-weave-pattern-background-vector-illustration-image.html

A pinstripe patterned weave has a single fine striped thread that looks like a line made up of pinhead shots

Eton stripe is a Plain weave variation with light and dark warp and weft – resulting in a straight vertical line of light and dark alternatively. Also called Hairline.

Chalk stripe weave results in light lines like the one made by a tailor’s chalk.

source: https://sewguide.com/fabric-weaving-types/

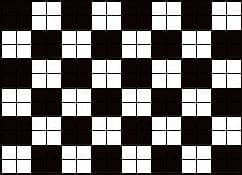

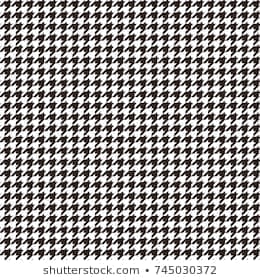

19 Checquered weaves

source: https://www.shutterstock.com/search/dog+tooth+pattern

This weave makes beautiful checks on the fabric. Think tartans and plaids

Block check weave has blocks of check patterns in light and dark yarns

A diamond weave is a twill weave with right and left twills looking like a diamond pattern

Two and two glen stripe with overcheck has one and one base with a two and two stripe

Three and Three has a twill base with three light three dark weft and warp

Shepherds check has a twill weave with five or more light, five or more dark warp and weft

Glenurquhart check has a twill weave with dark and light warp and weft coloured yarns to give a chequered effect.

Dog’s tooth has a twill weave with four or more light, four or more dark warp and weft

Gun club check has four or more light, four or more mid, four or more light, four or more dark, warp and weft.

source: https://sewguide.com/fabric-weaving-types/

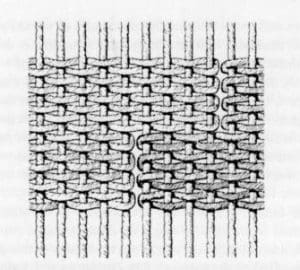

20 Double cloth weave

source: https://slideplayer.com/slide/5230985/

In this weaving technique, two fabrics are held together with another set of yarns. Sometimes, they are separated, as in the case with velvet.

source: https://sewguide.com/fabric-weaving-types/

Fabric with this weave : Velvet.

Reference:

https://en.wikipedia.org/wiki/Weaving

http://www.historyofclothing.com/making-clothing/history-of-weaving/

https://www.britannica.com/topic/textile/The-weaving-process#ref60768

https://sewguide.com/fabric-weaving-types/

Article Writtten By-

Ms. Sidrah Mubin Patel. B.Sc. in Textiles and Apparel Designing, Sir Vithaldas Thackersey College of Home Science.

Textile Value Chain Intern. Email: [email protected]