Textile finishing is the term for chemical and mechanical processes used on fabric after it’s manufactured but before it is cut and sewn into garments or made into other things. Textile finishing is used to achieve desired effects and it can have aesthetic or functional benefits. Finishing processes might modify a fabric’s final appearance, make it softer, or improve elements of its performance. Whichever process is done, textile finishing makes fabric more appealing to the consumer. Today, most fabric is manufactured in factories. Right after it is made it’s very dirty and harsh. You wouldn’t want to wear or use it for other things. In this state, it’s called greige goods or grey goods. This is why textile finishing is important. Those dirty, nasty grey goods need to go through finishing processes before they can be used for clothing, bed linens, interior furnishings, and other uses.

Types of Finishes

Bleaching:

source: https://textilelearner.blogspot.com/2011/03/textile-bleaching-process_5937.html

If the cloth is to be finished as white or to be given surface ornamentation, all natural colours must be removed by bleaching. This is also necessary if discoloration or stains have occurred during the previous manufacturing process. Bleaching can be done in the yarn stage as well as in the constructed fabric. Suitable bleaching agents are used to remove the colour from the fabric namely oxidizing or reducing bleaches. Bleaching is done for the cotton, woolen and silk. Man-made fabrics do not need bleaching, as they are naturally white. The kind of chemical to be used depends upon the kind of textile fiber of which the fabrics is composed.

Mercerizing:

source: https://textilelearner.blogspot.com/2012/04/mercerizing-finishing-process-effect-of.html

Mercerizing is an important preparatory process for cotton fabric. It is also used in the finishing of linen. The process consists of holding the fabric in tension while treating it with a strong solution of sodium hydroxide at a temperature of 70 to 80 F. Mercerizing causes the flat, twisted, ribbon like cotton fiber to swell into a round shape and to contract in length. The fiber becomes much more lustrous than the original fiber, and its strength increased by 20%. Mercerizing is done to improve the dye pick up.

Shearing:

source: https://www.indiamart.com/proddetail/fabric-shearing-machine-11026646991.html

Pile-weave fabrics and fabrics that have been napped are usually sheared to give an attractive smooth surface to the cloth. Shearing levels all surface irregularities caused by the plucking action in the napping process. On the other hand, patterns may also be cut into the pile fabrics by shearing to give a ‘sculptured effect’ of a design having high and low surface levels. Shearing is done by a machine which has rotating cylinders and helical blades. Its action resembles that of a lawn mover. After shearing, the fabric is automatically brushed to remove the sheared ends of the yarns.

Singeing:

source: https://textilelearner.blogspot.com/2012/03/what-is-singeing-process-of-singeing.html

Singeing is one of the first essential preparatory processes that impart smooth finish to fabric. Singeing burns off lint, threads, fuzz and fiber ends and leave an even surface before the fabric passes through other finishing processes or a printing operation. Singeing is accomplished by passing a gray goods rapidly over gas flame, usually two burners to a side, at a speed of 100 to 250 yards (90-225m) per minute. After the cloth leaves the burners it is pulled through water and then it is dried.

Beetling:

source: http://www.wmclark.co.uk/history-beetled-linen/

Beetling is a common finishing process for linen. The yarns are flattened by the impact of wooden mallets. This hammering actually closes the weave and gives the cloth a firm, flattened, lustrous appearance. All table linens under go this process, but dress linens are never beetled. Beetling differs from calendering.

Tentering:

source: https://www.indiamart.com/proddetail/tentering-frames-9641441362.html

This process is applied at various stages of finishing. Usually, the fabric is wet when it is run into a tender. Drying and evening of the fabric width are the primary purpose of the tendering. The tender frame consists of two endless chains carried in rugged rails with a distance between them that can be adjusted. The chains are equipped with clips or pins, which grip the selvage of the fabric and carry into the heated housing where a blast of hot air removes any moisture. Pin frames are mostly used on woollen or knitted goods; clip frames are favored for cotton. The tiny holes or marks are sometimes noticeable in the selvages.

Calendering:

source: https://www.indiamart.com/proddetail/automatic-textile-calendering-machine-11475654730.html

Calendering is essentially an ironing process that adds sheen to the fabric. The method varies according to the type of finish desired. Calenders are heavy machines made up of at least two rolls. One is usually of chilled steel; the other, a softer material like wood, paper, cotton fiber, corn husks or combinations of cotton and corn husk. The rolls are supported in vertical frames. Plain rolling calenders may have as many as seven rolls, four steel rolls and three horn husk or cotton rolls. The steel rolls may be equipped to be heated by gas or steam. The textile material is passed through the calendering machine rapidly between the gap formed by the rollers. This is done at an average rate of 150 yards (135m) per minute, and under pressure of 40 to 60 tons (550-827 MPa); the goods are then wound up on the back of the machine.

Embossing:

source: https://www.indiamart.com/proddetail/fabric-emboss-machine-17150929788.html

The process of producing raised figures or designs in relief on the surface of the fabrics by passing the cloth between heated engraved rollers is known as embossing. The process can be applied to the fabrics made of all types of fibers except the wool. To preserve the embossed finish of such fabrics, they should be washed in lukewarm water with a mild soap, never be bleached, and ironed on the wrong side while damp.

Napping:

source: https://www.indiamart.com/proddetail/raising-machines-2293625862.html

Napping is chiefly used to obtain a relatively deep hairy surface, but the degree of depth depends upon the technique used. The fabric is passed under a roller that has fine steel wires with small hooks on the ends. The hooks scrape the surface of the fabric pulling up fiber ends out of the yarn. The fuzzy finish, produced by napping makes a soft fabric that holds warmthness.

Starching:

source: https://www.indiamart.com/bestimpex-surat/finishing-and-starching-machine.html

Glue, wax, casein, starch and clay are used for cotton fabrics to give weight, stiffness and shiny appearance. Starch is applied on the fabric and passed between two rollers. Wax and oil are mixed together to the starch solution to give the shiny appearance to the fabric. Starching is a temporary finish.

Sanforizing:

source: http://www.technofashionworld.com/power-shrink-sanforizing-line-finishing/

Fibers spun into yarn are under constant tension during the weaving process. The yarns are made to assume a final condition by shrinking the fabric in a preparatory finishing process that minimizes subsequent shrinkage such as immersion in cold water. The factors that control the shrinkage are the stability of the fiber and the construction of the fabric. Construction is based on the type of the weave, the yarn twist and the yarn count.

The piece of fabric is taken and measured and then immersed in the water and the shrinkage of the fabric is calculated. Then the fabric is passed through the machine to make it shrink as to a desired measurement. This is known as sanforizing.

Wrinkle resistant finish:

source: https://www.fibre2fashion.com/industry-article/3532/wrinkle-resistant-cotton-fabrics

These finishes are also sometimes referred to as ‘crease-resistant’ or ‘Wash and wear’ finishes. DMDHEU namely Dimethyl Dihydroxy Ethylene Urea is used to impart wrinkle resistant finish on the textiles. The purpose of this finish is to prevent deformation of the fabric by undesirable and unintentionally introduced folds and rumples. Some finishes are more wrinkle-resistant than others, but fabrics treated with any of these finishes tend to smooth out when properly hung after wearing.

Flame retardant finish:

source: https://www.sciencedirect.com/science/article/abs/pii/S0144861717305714

A wide variety of flame retardant chemical finishes have been developed for application to fibers and fabrics. Carbonate and ammonium salts are used for flame retardant finish.

Antibacterial finish:

source: https://www.slideshare.net/Shameem_Byadgi/antibacterial-finishes

Chemical antiseptic finishes using Chitosan, impart a self-sterilizing quality to a fabric. The appearance and the feel of the fabric does not change and no chemical odour remains. Dry cleaning does not impair the finish.

Prevention of mildew:

source: https://www.slideshare.net/Shameem_Byadgi/antibacterial-finishes

Cellulose fibers are particularly susceptible to mildew. Silk and wool are also susceptible, but to a lesser extent. Such untreated fabrics will become stained, malodorous and eventually deteriorated by the fungus if allowed to remain in a moist condition for a period of time.

Shower curtains or other fabrics may be mildew proofed at home by soaking the material in soapy water, then, without rinsing, dipping it into a solution of boric acid and carbolic acid, which prevents rapid growth of the mildew fungus. The most effective mildew proofing agent is 0.05 per cent solution of phenyl mercuric acetate in water.

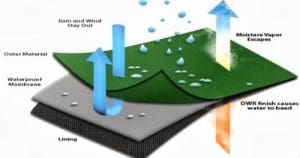

Water repellent finish:

source: https://textilelearner.blogspot.com/2013/08/repellent-finishing-mechanism-of.html

The fibres in the fabrics become covered with a film of synthetic resin. This repels and delays adsorption and penetration of water through the fabric. This finish allow air to permeate the fabric, and its comfort is largely retained in contrast with the water proof finishes.

Most of the original water proof finishes, produced by the application of rubber, waxes and oxidised oils, have been replaced by applying impervious films of polyvinyl chloride – PVC plastic. The low cost of this type of application, associated with the very light weight of the water proof fabric produced, compensates for the lack of comfort in the garment produced. For a fabric to be truly waterproof, it must be completely sealed with a substance that is insoluble in water. Modern waterproofing materials include the vinyl resins, which do not oxidize and crack as readily as rubber.

Reference

https://study.com/academy/lesson/types-of-finishing-in-textiles.html

https://en.wikipedia.org/wiki/Finishing_(textiles)

https://www.brainkart.com/article/Fabric-Finishes—Types—Basic-finishes,-Functional-finishes_1847/