HISTORY OF POWER WEAVING

The idea of starting factory production of cotton cloth and yarn in India took shape during the first two decades of the nineteenth century. The first cotton mill in India was established in Calcutta in 1818. The second cotton mill came into existence in 1830 in Bengal. The industry however found its most hospitable home in western India and especially in Mumbai. The first cotton textile mill called the Bombay Spinning and Weaving mill came into existence in Bombay in February 1856.

The Indian textile industry consists of.

- Traditional handloom sector with prim active technology

- Power loom sector which is a technologically improved form of handloom s and

- Com posited mill sector with its advanced technology.

All the three handloom sector is more scattered and spread throughout the country, and is seen in the villages, power loom sector is decentralized-scattered in and around some identifiable centers and the mill sector which is well organized and integrated to a large extent, a part of which is composited having spinning, weaving, and processing under the same roof.

POWER WEAVING A CHANGE

There was a change in the fortunes of the industry when yarn and cloth began to be produced on a mass scale on power-driven machines. The household enterprise handlooms could not face the changing situation. From sunrise to sundown a handloom weaver could not turn out four yards of cloth, while a Power loom on the same hour produces ten times the quality and quantity. The advent of the mill industry in the country was in the great interest of the situation. The birth of the industry was the necessity of the environment. Indian mills slowly replaced imported yarn and started supplying yarn to the handloom sector; the use of mill yarn by handloom weavers has brought a profound change in the social and economic status of the handloom weavers.

POWER LOOM- THE THIRD EYE

The traditional handloom s and textile mills were trying to fix their places in the industry. But both of them have certain limitations, it gave a chance to rise Power loom as a third pillar in the industry to overcome these limitations. Handloom s at the one hand has the least speedy production at higher cost and mills on the other hand require huge capital investments and scientific advanced technology. For speedy production on a small scale at distant places, the weavers started installing Power loom as ‘decentralized’ units.

POWER LOOM INDUSTRY IN INDIA

After independence many units in the mill sector started facing the problems. The technological changes were the need of the time and the mill sector could not meet this requirement. The labor problem also got multiplied due to the non-availability of skilled and trained workers. This resulted in a high cost of production and heavy losses to many units and finally closer to the mills. This adverse situation of mills also helped power looms to prosper fast. The factors like the wars, failure of mills, and the reservation for the handloom s helped power loom units to prosper very fast. All these are the external factors. Some internal factors also helped a lot in the development of these units. The very nature of the decentralized power looms is such that:

❖ It has reduced strain of operations

❖ It is less expensive

❖ Its installments are very easy because these are very small units.

❖ No labor laws are applicable.

All these favorable factors led the power loom sector to develop in small villages in the hands of small entrepreneurs and in scattered and far off areas. But this development is entirely unplanned. Today the power loom sector has developed a controversial subject. At one end. the handloom s- the traditional weaving says that the power loom units are eating its share in production and development and that’s why handloom s are lacking behind. Secondly handloom s cannot compete with the power looms because of their speedy production. At the other end the organized mill’s complains that many units are becoming sick because of power looms.

India manufactures 5% of cloth through the organized sector, 20% through the Handloom sector, 15% through the knitting sector, and 60% of Indian cloth is produced through the decentralized power loom sector.

The decentralized power loom sector is the lifeline of the Indian Textile Industry. India is having approximately 19.42 lakhs of power looms weaving almost 19,000 million meters of fabric, and provides employment to more than 7 million workers. The industry now produces a wide range of fabrics ranging from grey, printed fabric, dyed fabric, cotton fabric, a various mix of

cotton, synthetic, and other fibers. The country exports Rs. 44,000 million worth of goods to countries like the U.S.A., France, Germany, Bangladesh, Hong Kong, Italy, etc.

Although the growth of the power loom industry was slow initially; it has started gearing up now. The number of shuttleless looms has augmented to almost 50,000 and from this about 35,000 looms are working in the decentralized sector.

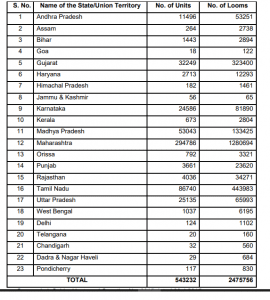

Most of the Power loom units are concentrated in semi-urban, or rural areas. Among all; Maharashtra has the highest number of power looms amounting to approximately 8 lakhs of the power loom, Tamilnadu is second with 5 lakh units, and Gujarat ranks third with 4to4.5 lakh worth of power looms.

THE INCEPTION OF POWER LOOMS IN INDIA

There are no authentic records to indicate the first introduction of the power loom in the country. The First power loom unit started in Ichalkranji town in Maharashtra in 1904 was also the first to start in the decentralized sector in India.

NUMBER OF POWERLOOMS IN THE COUNTRY STATE/UT-WISE

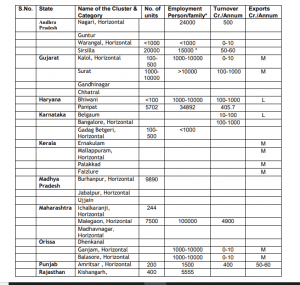

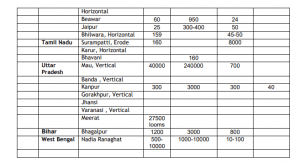

LIST OF POWER LOOM MACHINERY IN SOME OF THE CITIES IN INDIA

Solapur textile cluster – Rapier Loom

Sirsilla – The Centres Are Well Equipped With Modern Machinery And Equipment Such As Projectile, Rapier Looms, Air Jet, DropBox Looms, Pirn Winders, Cone Winders, And Wrapping Machine Etc.

Surat – Water Jet Machines, Rapier Machines, Air Jet Machines, Projectile Machines

Bhiwani Cluster – Shuttle-Less Power looms

Erode Cluster – Rapier, Air Jet,

Bhilwara Cluster – Air Jet Machines, Projectile Looms, Water Jet

Bangalore – Air-Jet, Water-Jets, Rapier

Jabalpur – Shuttle Less Power Looms

Malegaon – Plain, Semi-Automatic, Automatic & Shuttle-Less

Kishangarh – Rapier Looms Mostly

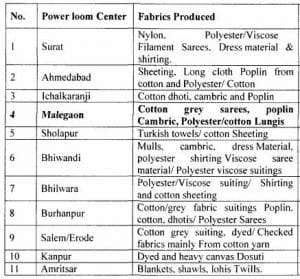

THE PRODUCTION PATTERN OF IMPORTANT POWER-LOOM CENTERS IN THE COUNTRY

PRESENT SCENARIO

Currently, modernization in looms is not satisfactory and the Indian industry still lags significantly behind the US, China, Europe, and Taiwan, etc. Most of the looms currently in the country are shuttle-less. There are less than 15,000 modern looms, whereas traditional looms are in large numbers. Value addition and the manufacturing of fabrics according to customer’s compliances, is not possible due to the obsolete technology of looms3. In the light of the above background, various challenges and adversities being faced by the Power loom Sector

CHALLENGES AND ADVERSITIES

1) A higher power tariff is one of the biggest challenges this industry is facing. Unlike the spinning industry weaving loom sector is mostly concentrated in small areas of nations, where power fluctuations are a matter of routine. Productivity also gets affected from time to time by fluctuating in power in such areas.

2) Another issue is the poor knowledge of many entrepreneurs, who feel that cheaper is always better and who are tempted to take shortcuts in their quest to curtail expenses. Their focus is absolutely short-term and they are more worried about surviving the current season rather than building up a competitive business. These shortcuts may include evasion of taxes and electricity tariffs, insufficient or improper selection and maintenance of machinery, exploitation of the labor pool, etc.

3) For most entrepreneurs, it is their family business. A few are aware of options such as technical textiles and specialty fabrics, which may offer them an avenue to earn better margins.

4) Most of the entrepreneurs in this field are basically investors without any technical knowledge. Another good avenue for spending the funds would be in training manpower but there is no coordinated effort in manpower training as the Indian loom industry is small scale unlike industry of China and Taiwan and therefore incurs high co-ordination cost.

5) Automation will also result in a reduction in the number of machines in each of these sectors (as each machine becomes more productive). This may create redundancy of jobs. Some effort also needs to be taken to ensure that those displaced are retrained and absorbed in the industry. Manpower training and organized placement services may address this issue.

6) Advance technology installation demand skilled labor to understand and install such facilities, shortage of skilled labor is also a roadblock in the adaptation of new technology in the weaving loom industry.

SCHEMES FOR THE DEVELOPMENT OF POWERLOOM SECTOR

For the purpose of promotion and development of various segments of the textile sector, particularly the power loom and handloom segments and also for the welfare of workers, weavers in this sector, the Government has initiated the following various schemes.

Integrated Scheme for Power loom Sector Development (ISPSD) In order to achieve the overall development of the power loom sector, the Government had announced the Integrated Scheme for Power loom Sector Development during 2007-08. The Scheme has various components:-

Marketing Development Programme for Power loom Sector (Buyer-Seller Meets and Seminars / Workshops):

Marketing Development Programme has a vital role in the power loom sector. Therefore, an activity for promotion and marketing of power loom products through different mechanisms such as the organization of Exhibitions and Buyer-Seller Meets (BSM), Seminars/Workshops, Publicity & Awareness Programmes, etc., have been implemented in association with Power loom Development & Export Promotion Council (PDEXCIL). During the period, April, 2014 to November 2014, twelve BSMs have been conducted and the fund released under the Scheme amounts to `1.31 Corers. A total of 30 Seminars and Workshops have been conducted for which GOI released Rs.0.20 corers during the period April, 2014 to November 2014.

Exposure visit by Power loom Weavers to Other Clusters:

The power loom weavers in the clusters using technology below par are not exposed to other areas using a higher level of technology to produce diversified textile products or value-added fabrics owing to limited technical knowledge and financial constraints, etc. With a view to overcoming such difficulties, the power loom weavers in different clusters, are encouraged to visit other developed clusters to get familiarized with the benefit of upgraded technology, diversified products, and the marketing techniques adopted in those clusters. The Regional Offices concerned to assist the power loom weavers during the exposure visits and facilitate effective and meaningful interaction.

Common Facility Centre (CFC):

CFC provides infrastructure support to the Power loom weavers associated in a group and is willing to set up the Common Facility Centre. · It also includes house design center/studio, testing facilities, training center, information- cum-trade center and common raw material/yarn/sales depot, water treatment plant for industrial use and common pre weaving facilities viz. warping, sizing, etc. under the projects in PPP mode for backward and forward integration as per the need of the cluster.

Group Workshed Scheme (GWS)

The Government of India introduced a Group Workshed Scheme for the decentralized Power loom Sector on 29 July 2003, under the X the Five-Year Plan. The Scheme aims at setting up Power loom Parks with modern weaving machinery to enhance their competitiveness in the Global Market and the same was subsequently modified. Under the Scheme, 102 projects have been approved up to November 2014, providing Government subsidy on an eligible construction area of 32.02 lakh square feet. A total subsidy of Rs.29.74 corers has been released as on 30.11.2014.

Margin Money Subsidy (MMS) Scheme

The Government is implementing 15 percent, 20 percent, and 30 percent Margin Money Subsidy (MMS) under Technology Up-gradation Fund Scheme (TUFS) for Power loom Sector, especially to modernize the decentralized Power loom Sector7. Funds utilized/ Subsidy given under the Schemes is shown in Annexure-II

Comprehensive Power loom Cluster Development Scheme

The Comprehensive Power loom Cluster Development Scheme was formulated in the year 2008-09 to develop Power loom Mega Clusters at Bhiwandi (Maharashtra) and Erode (Tamil Nadu), Bhilwara (Rajasthan), Ichalkaranji (Maharashtra) and Surat (Gujarat), respectively. Its aim is to create world-class infrastructure and to integrate the production chain in a manner that caters to the business needs of the local Small and Medium Enterprises (SMEs) to boost production and export. The broad objective of the Mega cluster approach Scheme is to enhance the competitiveness of the clusters in terms of increased market share and to ensure increased productivity by higher unit value realization of the products. The Scheme provides requisite support /linkages in terms of adequate infrastructure, technology, product diversification, design development, raw material banks, marketing & promotion, credit, social security, and other components that are vital for the sustainability of weavers engaged in the decentralized power loom sector.

Group Insurance Scheme for Power loom Workers (GIS)

The government of India launched a Scheme for the welfare of Power loom workers through the Group Insurance Scheme, in association with LIC, from 1 July 2003.

Newly Launched Schemes

Pilot Scheme of In-Situ Up-gradation of Plain Power looms:

The Pilot Scheme of In-situ Up-gradation of Plain Power loom for Small Scale Industries (SSI) was launched on 11.09.2013 on a pilot basis in selected clusters in eight States to provide financial assistance to economically weak, low-end power loom units. Ø The scheme aims to improve the quality and productivity of the fabric being produced by upgrading their existing plain loom with certain additional attachments and enable them to face the competition in domestic and international markets. It aims at covering 99,000 looms during 12th Five Year Plan. Ø Financial assistance of Rs.15,000/- per room will be given to the power loom units for upgrading ordinary loom by installing specific/ identified attachments (kits) into semiautomatic to the maximum of 8 looms per weaver are eligible under In-situ scheme. Ø In-situ Up-gradation of plain power loom has been approved for 17 clusters at Sircilla, Mau, Tanda, Burhanpur, Bhagalpur, Malegaon, Nagpur, Ichalkaranji, Bhiwandi, Surat, Ahmedabad, Somanur, Ludhiana, Kishangarh, Nagari, Hindupur, and Dholka.

Health Insurance Scheme for Power loom Weavers:

The Health Insurance Scheme for power loom weavers has been approved for implementation in the 12th Five Year Plan. The Scheme provides the power loom weavers and ancillary workers comprehensive (IPD and OPD) healthcare assistance for a wide range of ailments including all pre-existing/ new diseases.

Hire-Purchase Scheme for Power loom Sector under TUFS:

This Scheme has been approved and notification to this effect has been made under the Revised Restructured Technology Up-gradation Fund Scheme (RR-TUFS). Under the Scheme, the hirer (SPV) would procure the machines and then provide them on hire purchase basis to the weavers. The risk and rewards incidental to the ownership of the asset are transferred to the purchaser but not the actual ownership until the end of the period. Ultimate ownership will transfer only at the end of the term of hire-purchase.

powerloom DEVELOPMENT AND EXPORT PROMOTION COUNCIL

The Power looms Development and Export Promotion Council (PDEXCIL) is the nodal agency for the development and promotion of exports of power loom products. The Council undertakes direct promotional activities such as participation in international trade shows, sending and hosting trade delegations, and sustained image building exercise through advertisements abroad, publications, and audiovisuals.

REVAMPING INDIAN POWERLOOM SECTOR

In spite of various schemes being implemented for the promotion of Power loom Sector, the recent strike in the Bhiwandi cluster of Maharashtra, in the month of August 2015, is the burning example of recession in the Sector. The strike has brought half of India’s power loom sector to a halt. The striking power looms are demanding Government intervention over control on yarn prices, permission to export cloth and restructuring of duties and taxes, and also giving direct subsidy to farmers instead of procurement of cotton at minimum support prices by the State Governments11.

As an initiative, the Ministry of Textiles had constituted an Expert Committee headed by Shri Ajay Shankar, Member Secretary, and National Manufacturing Competitiveness Council for reviewing/revamping the Textile Policy 2000. The Expert Committee has since submitted a draft Vision, Strategy, and Action Plan based on which formulation of a New National Textile Policy 2015 is under process to promote all sectors of Textile Industry i.e. handloom, power loom, and Khadi also to resolve various challenges faced by power loom sector.

CONCLUSION

The power loom sector occupies a pivotal position in the Indian textile industry. Though current growth of this sector has been restricted by technological obsolescence, fragmented structure, low productivity, and low-end quality products, in future Technology would play a lead role in this sector and will improve quality and productivity levels. Innovations are also be happening in this sector.

To reap benefits of these developments Indian Power loom Industry has to prepare itself for drastic technological changes and will have to focus on areas such as Technology up-gradation: modernization of Power loom Service Centres and testing facilities; Clustering of facilities to achieve optimum levels of production; Welfare schemes for ensuring a healthy and safe working environment for the workers in future

REFERENCE

https://www.fibre2fashion.com/industry-article/3218/indian-powerloom-sector

http://164.100.47.193/Refinput/New_Reference_Notes/English/Powerloom.pdf

https://shodhganga.inflibnet.ac.in/bitstream/10603/147213/15/09_chapter%203.pdf

https://www.dcmsme.gov.in/reports/solapurtextile/13Autoloom08.pdf

http://www.jetir.org/papers/JETIR1712145.pdf

http://ministryoftextiles.gov.in/sites/default/files/StudyReport-SecondHandloomShuttleLoom.pdf

https://shodhganga.inflibnet.ac.in/bitstream/10603/31845/4/chapter_ii.pdf

http://clusterobservatory.in/dsr/124.pdf

Article written by Swati Patali B.Sc in Textile and Apparel Designing from Sir Vithaldas Thackersey College of Home Science. Textile Value Chain intern.