A non-fruit orienting species of banana, abaca (Musa Textilies), has been developed for centennial as a fabric filament. Additionally, recognized as “Manila Hemp”, banana filament manufacturing & its dealing have been targeted essentially across The Philippines because of the vegetation abundance & speedy germination.

What is an abaca banana?

Bananas emerge on plants, instead of trees, with the fruit precisely being a berry.

The leaf covering across the bottom of this blooming plant is where one can discover a concealed filament resource – and not in the fruit.

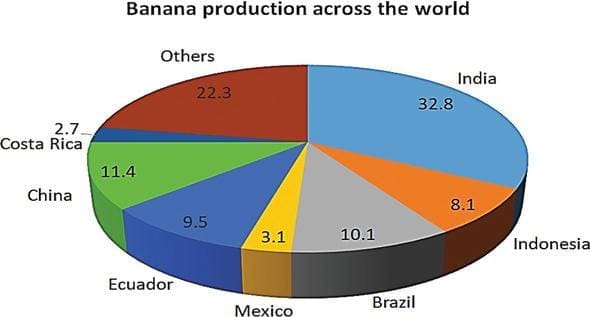

Organic fibers have vital benefits like low density, relevant stiffness, and mechanical properties, and peak sustainability. In addition, they’re renewable and biodegradable. There has been a lot of investigations on the utilization of organic fibers in the build-up. Banana fiber, a lignocellulosic filament, acquired out of the pseudo-stem of the banana plant (Musa sepientum), is a bast fiber with remarkably good habitual properties. The banana plant is a huge perennial herb with leaf coverings that become pseudo stalk. Its peak can be 10 – 40 ft (3.0-12.2 meters) encircling with 8-12 huge leaves. The leaves are as much as 9 feet in length and 2 feet broad (2.7 meters and 0.61 meters). The banana plant is accessible all over Southeast Asia India, Bangladesh, Indonesia, Malaysia, the Philippines, Hawaii, Thailand, and a few Pacific islands.

Attributes of Banana Fiber:

Banana fiber has its individual physical and chemical features and numerous qualities that make it an admirable filament.

1.The occurrence of banana filament is synonymous with that of bamboo and ramie filament. However, its sheerness and spinnability are superior to the two.

2.The chemical configuration of banana filament is cellulose, hemicellulose, and lignin.

3.It is an extremely strong filament.

4.It has a compact prolongation.

5.It has a bit glossy aspect relying on the extraction & spinning process.

6.It is translucent.

7.It has powerful wetness socking quality. It absorbs, in addition, to liberate wetness quickly.

8.It is decomposable and has no refusal impact on climate and hence, can be classified as an organic fiber.

9.Its standard fineness is 2400Nm.

10.It can be spun across all the procedures of spinning counting ring spinning, open-end spinning, bast fiber spinning, and semi-worsted spinning amidst others.

Banana Fiber uprooting, spinning & weaving:

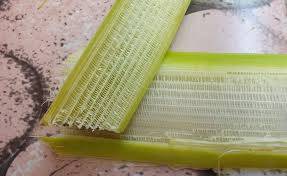

The uprooting of the organic fiber from plant essentials for required care to confront damage. In the latest experiments, banana plant segments are pierced from the focal stalk of the plant and then rolled gently to detach the extra wetness. Impurities inside the rolled filaments in particular: pigments, smashed filaments, layering of cellulose, etc are eliminated manually by a comb after the filaments are being wiped clean and then dried. This automatic and manual uprooting of banana fibers was unvaried, inefficient, and caused destructiveness to the filament. Therefore, this type of approach may not be approved for commercial demand.

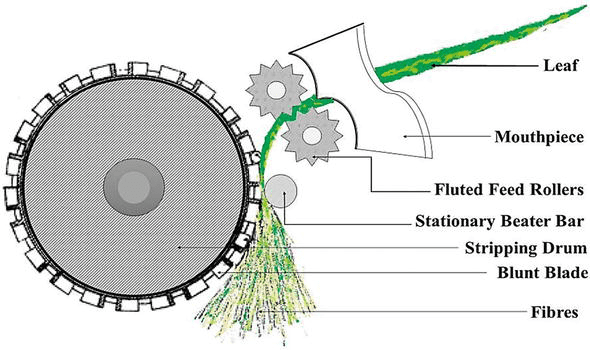

An appliance utilized for uprooting banana fiber consist of horizontal beams with a carriage connected and an exceptionally designed comb that could move back and forth. The fiber uprooting by utilizing this method can be executed directly via placing a clean section of the banana stalk at an anchored platform of the appliance and attached on the ends by jaws. This removes the relative motion of the stalk and prevents early damage to the filaments; this is followed after cleansing and drying of the filaments in a chamber at 200 0C for 3 hours. These filaments are then categorized and prepared for the lamination process.

Once the fiber is assembled, the procedure then moves to yarn spinning. The investigators look over the established operations, which utilize the fibre yarns in weaving the banana fabric. The research found that the convention process is very time-wasting. Therefore, is not suitable for modern use. Hence, this testing has explored an open-ended spinning system for fibre evolution. The yarn is trimmed to a 3-centimeter extent for the spinning procedure.

After yarn spinning, weaving is terminated inside the looms in line with the standard procedure like other materials.

Applications of banana fibre

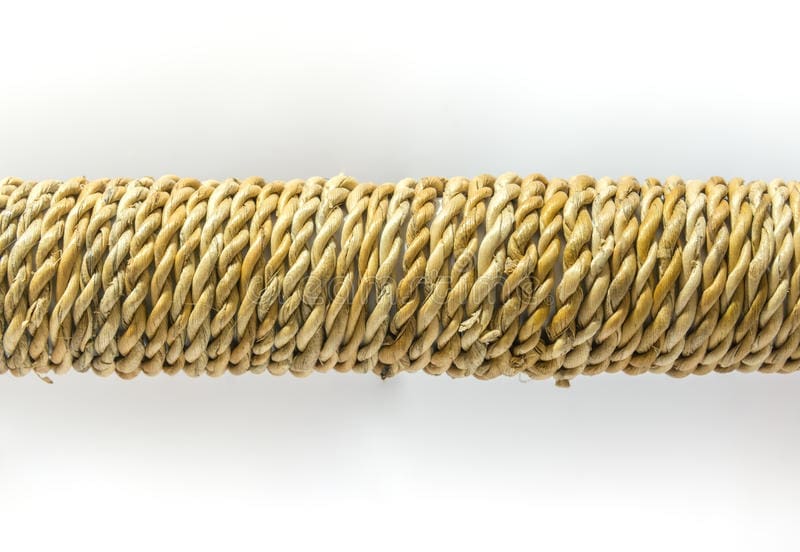

One of the common banana stem fiber merchandise constructed nowadays is rope and cordage. The seawater resistance of the banana stem fiber and its organic lightness property has made a market for this filament in the transport line manufacture. This fiber is additionally utilized to supply fishing nets, varieties of cordage, mats, packaging, sheets, etc. Besides, the Edo duration of Japan (1600–1868), banana stem fiber was utilized to manufacture traditional attire along with kimono and kamishimo. This filament is typically used due to its mild weight and comfort. Moreover, banana stem fiber is in manufacturing cushion covers, bags, table cloths, curtains.

Besides, there are a few potential uses of banana fibers, such as an organic absorbent, for manufacturing of mushrooms, arts/handicrafts, string thread, paper cardboard, tea bag, and top quality textiles/cloth materials, currency note papers, and many other merchandises. The use of banana fiber as an organic absorbent besides has good potential to soak oil spilling in oil refineries. It additionally can be used as an absorbent in colored wastewater from the dyes of fabric enterprises. Banana and banana stem include pathogenesis proteins, those own antimicrobial properties. The stem can be transformed into organic matter, it also holds a huge quantity of cellulose and starch, and can be utilized as cattle feed. Additionally, several investigations described using banana stem fiber in the fabrication of polymer/fiber synthesis.

Conclusion

Banana plants are examined as the world’s most convenient plants. Nearly all the sections of this plant, for instance, fruit, peel, leaf, pseudo-stem, stalk, and inflorescence, can be utilized. Nonetheless, the banana stem normally turns into biomass waste as soon as the harvest period of banana fruit is completed. Hence, investigators have commenced withdrawing the filaments and different constituents from the stalk and utilized them to manufacture numerous merchandise.

Reference:

- https://www.the-sustainable-fashion-collective.com/2019/06/03/what-is-banana-fibre-and-how-do-you-make-textiles-from-it

- https://textilelearner.net/banana-fiber-properties-manufacturing/

- https://www.intechopen.com/books/banana-nutrition-function-and-processing-kinetics/banana-pseudo-stem-fiber-preparation-characteristics-and-applications

Image source:

- https://encryptedtbn0.gstatic.com/imagesq=tbn:ANd9GcScyt4zf4_tiXuIMq2FUBHFdlbT2lnevrwYlQ&usqp=CAU

- https://www.intechopen.com/media/chapter/64570/media/F2.png

- https://thumbs.dreamstime.com/b/banana-fiber-twist-rope-white-tone-background-58133262.jpg

- https://lh3.googleusercontent.com/proxy/Y3ox2jCZrCvv3Tb9_wL99rKMNlEDKr_ucvbBXe-qjmVYRM9rAgZz_hh545MjHhl_XFoIX8AI0sqSZP8ADreq3YMplU7gCm3UwHM0_v6VCEEzINB26SITG-UYITrcfG3iQ7cePEL0ChmcnbtojDJWZjLX9EjmN_LEeemRnM52mAf28H-q1wqz2-HT3yv0mXwUoBQCzzEjStLVOF6zX13LqQjt4K6bNNuZ87_gmA

- https://64.media.tumblr.com/41ec23fdc596702a7efbca175f084296/tumblr_mhbgikJFtv1s47hb7o1_1280.jpg

- https://www.intechopen.com/media/chapter/64570/media/F4.png

- https://i.pinimg.com/originals/80/92/d4/8092d41daf0f08ce744ad4ba5493d42d.jpg

- https://img3.exportersindia.com/product_images/bcfull/2020/10/7307897/1603691864_p_5617343_1195279.jpeg